Application

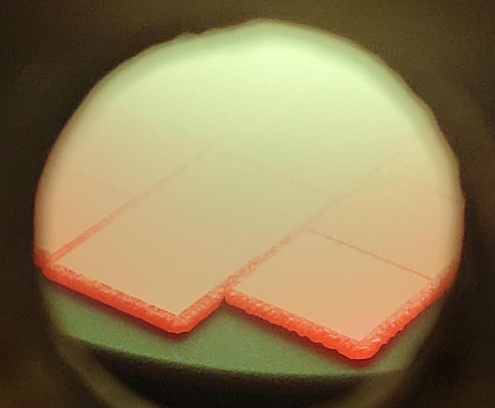

Preparation of high-quality single crystal diamond;

Preparation of high-quality polycrystalline free-standing diamond films;

Preparation of high quality polycrystalline diamond films;

Preparation of various carbon nano films such as graphene, carbon nanotubes, fullerenes and diamond films.

Features

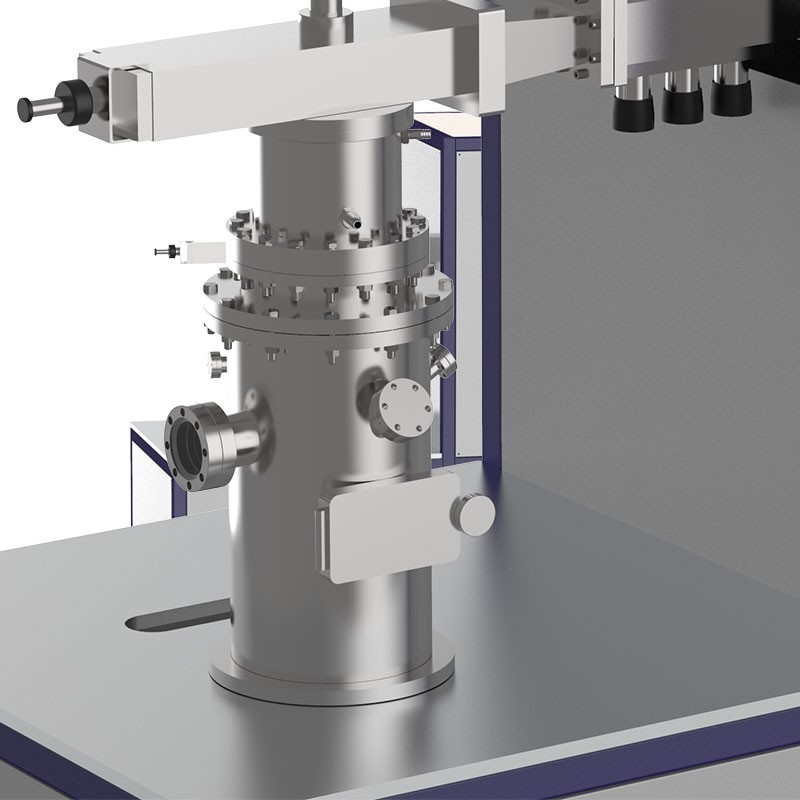

a. Stainless steel cavity type 6kw microwave plasma equipment, high power density;

b. The water-cooled substrate stage and the water-cooled metal chamber ensure the system can work stably for a long time;

c. The substrate temperature is achieved by microwave plasma self-heating;

d. The vacuum measuring instrument adopts a full-range vacuum gauge, which can accurately measure the background vacuum and working gas pressure;

e. The vacuum pump and valve adopt turbo molecular pump (the ultimate vacuum is 1×10-5Pa) and the rotary vane mechanical vacuum pump (the ultimate vacuum is 1Pa), and the system can automatically control the deposition pressure;

f. Cooling water circulation system to ensure long-term safe and stable operation of the device under high power;

g. 15-inch touch screen, PLC automatic control, can set the temperature or pressure to be constant, can save and reuse up to 20 sets of process files;

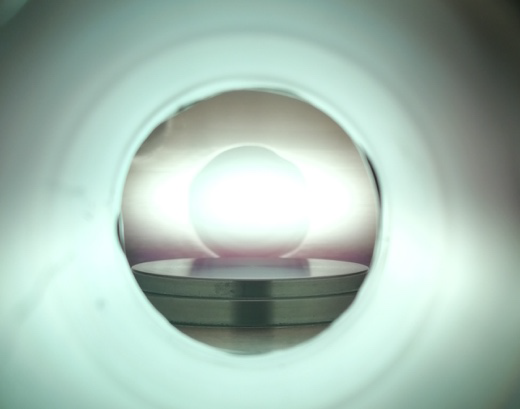

Fully automatic process control module, which can stably and reliably prepare high-quality diamond films and crystals

Technical specifications

Microwave system (Sairem microwave source, France) | microwave frequency | 2450±25MHz |

output power | 0.6kw~6kw continuous adjustable |

Microwave tuning | 3-stub tuner Mode conversion antenna |

Microwave reflection protection | Circular,Water load |

Microwave operating mode | TM013 |

microwave leak | ≤ 2 mw/cm2 |

vacuum system | Operating pressure range | 10~250Torr |

Automatic pressure control | 40~250Torr |

Vacuum pump | 4.4L/s rotary-vane vacuum pump |

Vacuum integrity | < 1.0x10-9 Pa * m3 /sec (by Helium leak detector) |

Pressure holding capacity | The pressure rise is less than 0.2 Torr every 24 hours |

Ultimate vacuum | 0.1Pa(7.5 x10-4 Torr) |

Vacuum measurement | Brand film gauge |

Vacuum reactor | Reactor materials and structures | double-layer water-cooled stainless steel |

Vacuum seal | Metal seal + fluororubber ring seal (load door) |

Reactor ID | φ140mm |

Sample table window | 105x50mm Rectangular port, Front door sealed with Fluorine O-ring |

Watch window | Two ports, CF35 large bore, 180 ° distribution |

Temperature measurement window | The horizontal angle of the two windows is 25~30°, 180° distribution; The window is convenient to detect the temperature of the sample stage from the oblique angle of the upper part of the reactor downward |

Sample stage | Electric lift water-cooled substrate platform φ100mm,Adjustable height range 0~70mm |

When the diameter of molybdenum substrate is ≥50mm, the plasma fireball can cover the whole substrate stage at 5000W and 180torr |

Substrate temperature 250~1400℃ Depending on the process parameters |

Gas channel | Flowmeter and flow control valve imported from Japan |

system-provided 4-channel MFC |

4MFC maximum flow:H2: 1000sccm,CH4:100sccm,O2:20sccm,N2:2sccm |

Temperature measurement system | German Raytek infrared temperature measurement system, temperature range: 300 ~ 1300 ℃ |

Systems software | 15”touch screen with PLC control, friendly user operating interface |

The system supports two levels of users: engineer and operator, and provides user authority management function |

The system is equipped with automatic protection such as water shortage, air shortage, power supply phase failure, fireball jump, over temperature overload, ignition and so on |

Up to 10 sets of process recipes can be set, each set has 40 rows of data, the production process is automatically controlled by the process recipes, and the process data can be backed up and exported via U disk |

The system comes with fully automatic air extraction, ignition, heating, cooling and other preset processes, easy for users to operate |

Fully automatic temperature control and air pressure control greatly reduce the workload of system operators |

System installation requirements

The following installation conditions are provided by the customer:

1. Gas connection

a) Working gas path: users need to provide four channels of CH4, H2, N2 and O2, the gas pressure is 0.2MPa, and the gas purity is determined by the user according to the process requirements

b) Gas interface: 1/4"VCR interface

2. Power supply

a) Power supply voltage: AC 380V (± 10%), frequency 50 Hz, three-phase four wire, There is independent ground wire in the room, the efficiency of grounding resistance is 4 Ω, and the maximum power is 20kW

b) It is recommended to reserve a separate air switch on the wall 1 meter away from each equipment. The specification of air switch is 4P32A and with leakage protection.

c) Before making any connections, the electronic system in the system should be shut down.

3. Cooling water

Customers need to provide their own industrial chillers:

a) Cooling capacity:10kw

b) Flow rate:>30L/min

c) Recommended inlet water temperature:20℃,maximum inlet water temperature<25℃

d) Inlet water pressure:≥5.0 kg/cm2 (or head>45 m)

e) System water inlet and outlet connection:φ19mm(pagoda joint)

f) In order to avoid problems caused by corrosion, pure water is recommended

4. Compressed air demand for system control

a) Compressed dry air (CDA): the system needs to provide CDA gas path with gas pressure ≥ 0.4MPa.

b) Interface: φ 8 quick plug (pneumatic quick plug)

5. Equipment exhaust

a) Customers need to prepare their own exhaust channels, and the exhaust port of the equipment is connected to the exhaust channel through the KF25 interface.

Check before acceptance

1. Vacuum leakage: the leakage rate of vacuum chamber is less than 0.1torr/12h

2. Microwave leakage: the measured value is less than 2MW/cm2 (when the microwave output is 5kW)

3. Water pipe leakage: make sure the water pipe is not leaking

4. System test: the system can start and run normally, and the plasma fireball is even and stable

Warranty

1.Grantee period is 12 months from the date of acceptance of the system or 14 months from date of shipment (Airwaybill date), whichever comes first.

2.The following are not covered by warrantee:

a)Unauthorized modification of hardware/software.

b)Improper operation which are not mentioned in the user manual.

c)Consumable parts

3. Customers need to ensure that the construction progress of public facilities such as gas, electricity and water will not affect the installation and commissioning of the equipment and the delay caused by this will not extend the warranty period.