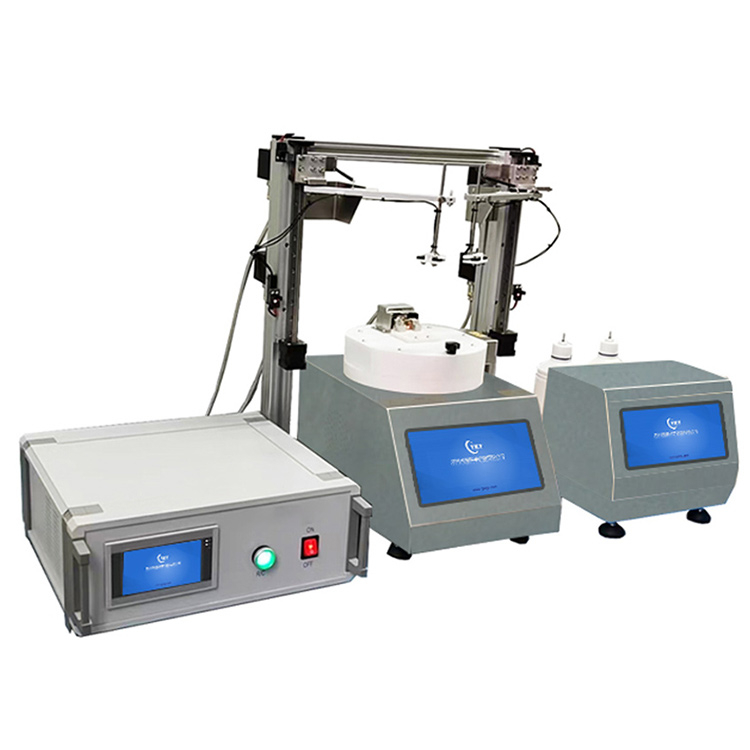

Fully automatic multi-layer perovskite rotary coating machine is suitable for coating perovskite materials, as well as for surface coating processes in semiconductors, crystals, optical discs, and plate making. The machine achieves automatic dripping, spinning, and drying of the entire process; it can simultaneously alternate between two types of films, with each liquid alternating up to 500 times, achieving the coating of thousands of layers of thin films. The machine can be used for coating solutions with acidic or alkaline properties. The equipment comes with vacuum suction cups of different sizes, which can be selected according to the size of the sample, and fixed to the substrate using vacuum adsorption. This machine is mainly used in laboratories of universities and research institutes for the generation of thin films.

Main features:

1. Vacuum adsorption method for fixing samples, easy to operate.

2. Using positioning tools, samples can be easily placed in the center position to reduce vibration or flying debris caused by eccentricity.

3. Different suction cups can be used according to the sample size, and replacement is convenient and simple.

4. The motor adopts a 24V DC brushless motor, with high reliability, strong adaptability, simple maintenance and repair, low noise, small vibration, stable operation, quick and stable start-up, and smooth operation after acceleration, which can ensure the consistency and uniformity of the coating thickness.

5. Using an oil-free vacuum pump, it has the advantages of small size, simple structure, easy operation, convenient maintenance, and no environmental pollution.

6. The chamber is made of polytetrafluoroethylene material, with a longer service life, excellent chemical corrosion resistance and stress cracking resistance; the body is made of sheet metal structure, sturdy, durable and lightweight.

7. After heating, it can be quickly cooled by ventilating gas.

8. Chinese operation interface (full English operating system optional)

9. With lid opening protection function, when the upper cover is opened during the coating process or after the coating is completed, the machine will immediately decelerate until it stops.

10. The control interface adopts touch screen control, which is simple and convenient to operate, and the display is intuitive.

11. Fully automatic coating process: automatic dispensing, automatic ventilation, automatic spin coating, automatic drying.

12. Two liquids can be alternately coated, and up to 1000 layers of thin film can be coated.

Technical parameters:

product name | CY-SPC-100MLFully automatic multi-layer perovskite rotary coating machine |

Product model | CY-SPC-100ML |

Installation conditions | This equipment is required to be used below an altitude of 1000m, at a temperature of 25 ℃± 15 ℃, and at a humidity of 55% Rh ± 10% Rh. 1. Water: No need 2. Electricity: AC220V 50Hz, must have good grounding. 3. Gas: Compressed gas or self prescribed protective gas 4. Workbench: size 600mm × 600mm × 900mm, with a load-bearing capacity of over 50kgs |

Parameters | 1. Power supply: host 24V Peristaltic pump 24V heating: 220V 50HZ 2. Power: Total power 1200W Heating: 1350W 3. Rotating speed: 500-10000rpm (minimum increment is 1rpm.) 4. Running program: The machine can be divided into two groups to complete each coating: AB and AB. Each group of programs is divided into six sections to run, and each group of programs can cycle 500 times. The two groups of programs can apply up to 1000 layers of film. 5. Setting range of increase/decrease rate: 10rpm/s -2000rpm/s (in increments of an integer multiple of 10) 6. Heating function: Heating range: RT-200 ℃ (chamber made of heat-resistant and corrosion-resistant PTFE material) (carbon fiber heating tube) 7. PTFE vacuum suction cups and aluminum suction cups, specifications: 1 inch, 2 inches, 4 inches. |

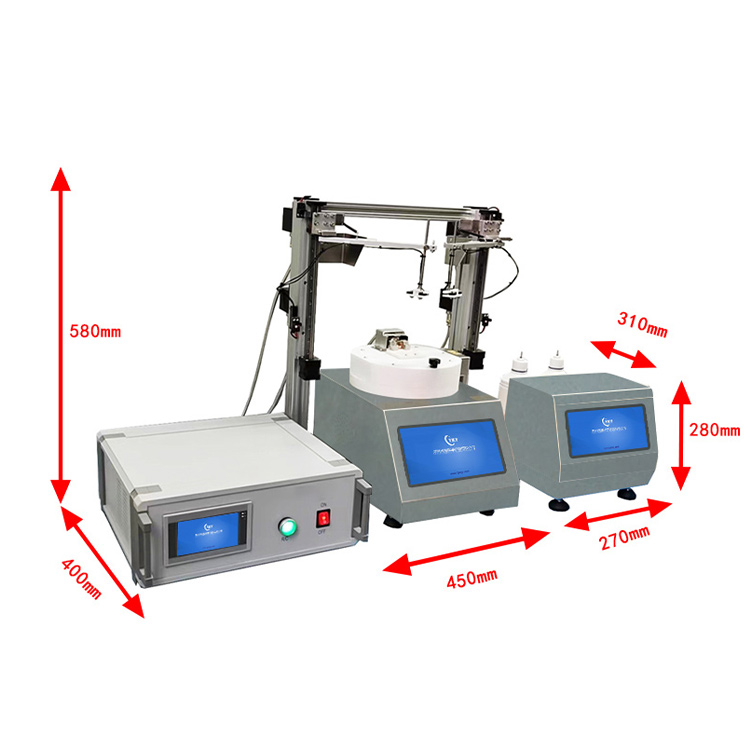

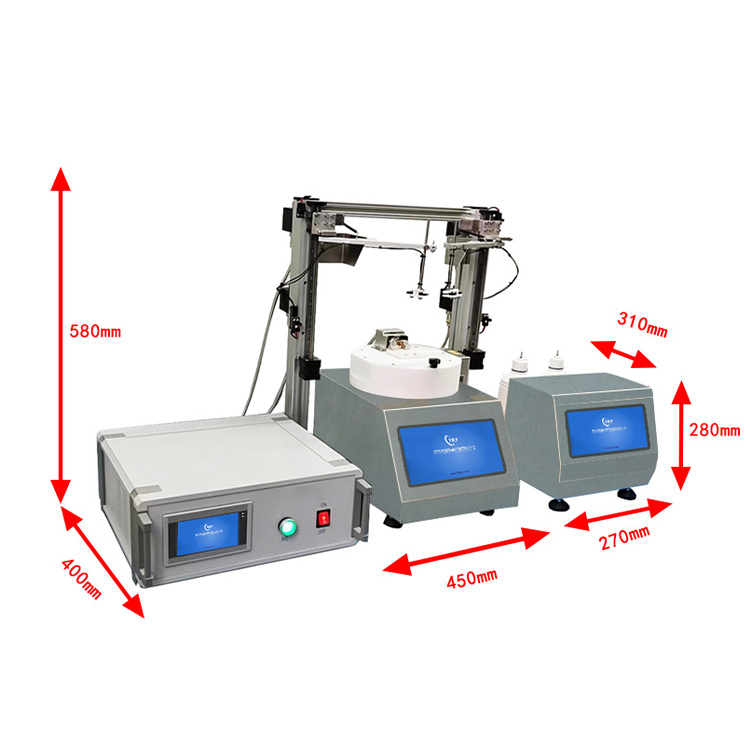

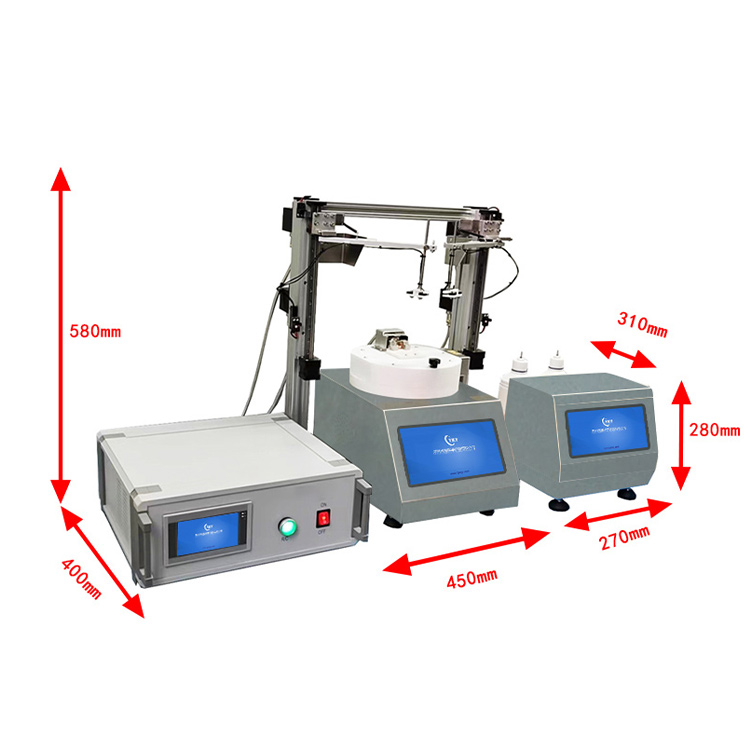

Product specifications | Size: spin coating machine 450x400x580mm; Peristaltic pump 270x310x280mm; Weight: 50kg |