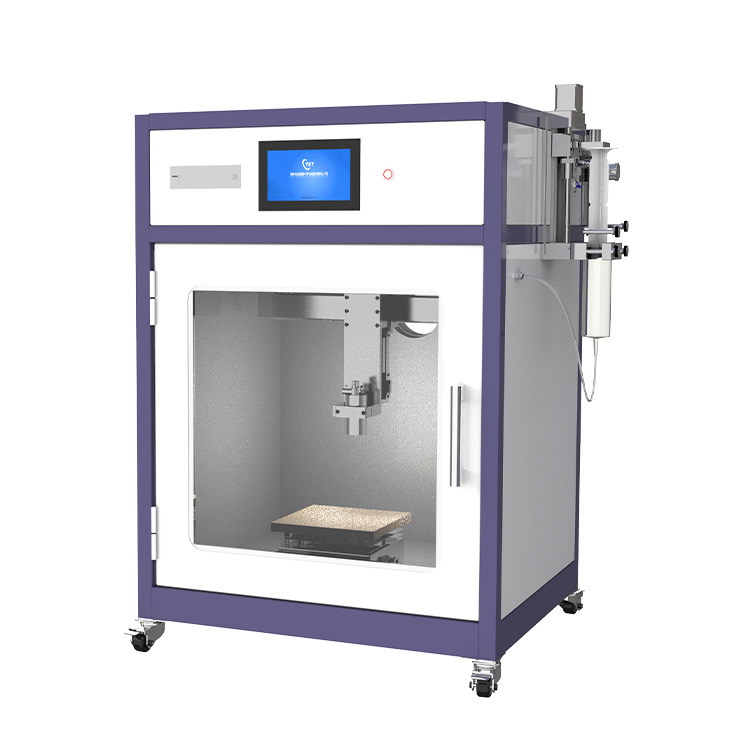

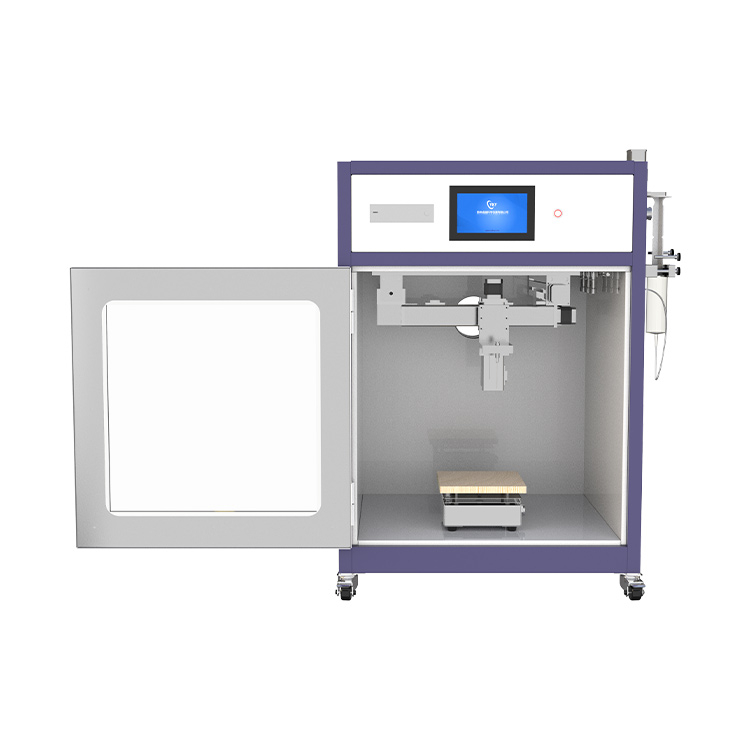

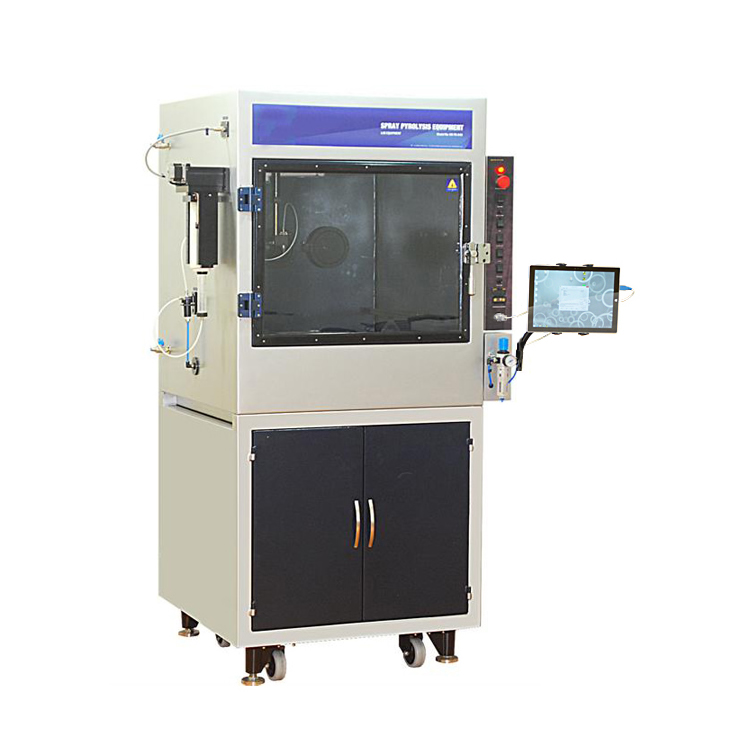

The spray pyrolysis film preparation method is to atomize the solution and spray it onto a heated substrate, and then obtain a desired material structure on the substrate. This equipment is an ultrasonic spray pyrolysis equipment independently developed by our company. It is equipped with 40KHz 130W ultrasonic sprayer, PID temperature-controlled substrate heater plate, high precision peristaltic pump and precision programmable stepping motor moving mechanism. The integrated design of the device can accurately control the parameters such as the amount of solution, the speed of the spray particles and the size of the spray particles, and the substrate temperature can also be controlled to meet your various experimental needs.

Ultrasonic spray pyrolysis coater application range:

Product name | Automatic ultrasonic pyrolytic spraying CY-USP30-A |

Control mode | Automatic touch screen control |

Sample size | 2.54mm*2.54mm |

Deposited film | 10cm*10cm FTO transparent electrode |

Supply voltage | AC110V,60Hz |

Maximum power | 3.5KW (about 1.5KW including compressor and peristaltic pump) |

Ultrasonic atomizer | 50KHz 30W |

Liquid viscosity | 1-50mPa·s(cP) |

Nozzle stroke | X-Y axis Max 180mm |

Velocity of movement | 0-100mm/s (X-axis) 0-100mm/s(Y-axis) |

Heat the substrate substrate | 200mm X 200mm |

Maximum temperature | 500℃ |

Temperature control mode | AI-PID temperature control |

Exhaust device | The equipment is provided with an exhaust device so that

the decomposed gas can be discharged from the exhaust outlet device |

Injection method | High flow injection pump |

Communication protocol | In Windows, the default communication port is RS485 or RS232 |