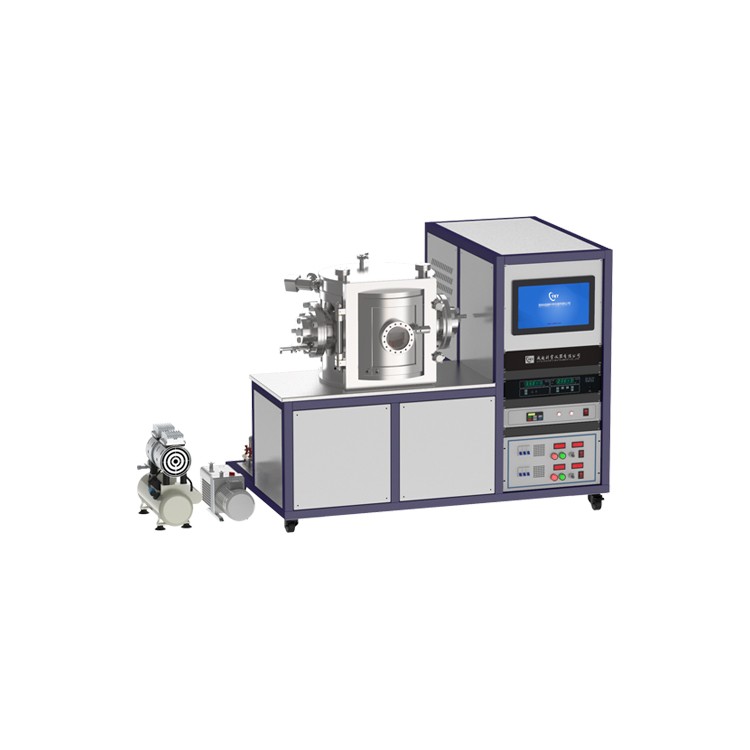

Three Evaporation Source High Vacuum Coater is a high-vacuum coater with three evaporation sources. The equipment adopts a front door type vacuum chamber design, which has a large chamber space and strong expandability, which can meet the evaporation coating of multi-style and large-size samples. The chamber is equipped with an upper sample stage, and the clamping or clamping sample mounting parts can be selected according to the user's sample style. The sample stage is rotatable, heated, and all operations are integrated through the touchscreen. The vacuum pump group of the equipment is a two-stage vacuum system, which consists of a bipolar rotary vane vacuum pump and a turbo molecular pump, which can provide a clean and oil-free high vacuum environment for vacuum coating experiments; the vacuum system contains a complete pneumatic valve system, users can One-button operation through the touch screen realizes operations such as vacuum extraction, non-stop sampling, and complete shutdown.

high vacuum evaporation coater Detail intruduction:

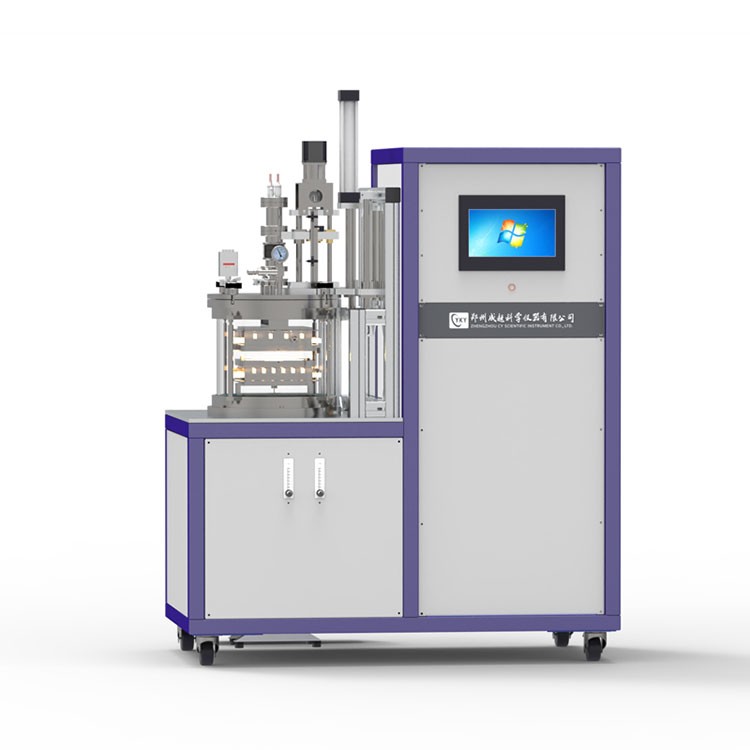

There are three groups of evaporation sources in this equipment, which are tungsten boat evaporation sources and water-cooled copper electrodes, which can support a maximum current of 260A, and the heating temperature can reach up to 1800℃. It can realize the evaporation of various refractory metals. The three groups are independent Thermal evaporation source, will not cause mutual contamination of plating materials. The equipment adopts an integrated design, the cavity and the electric control part are separated left and right, which realizes the separation of water and electricity, and effectively ensures the safety of users. The electronic control part adopts the design of the combination of touch screen and button panel. Auxiliary functions such as vacuum system and sample stage are operated by one button on the touch screen, and power-on evaporation and film thickness control are operated independently through the panel, which is as convenient as possible for users at the same time. Avoid the possibility of misuse. The equipment has perfect design and excellent performance, and is a must-have for high-precision evaporation coating experiments in laboratories.

high vacuum evaporation coater Application areas:

Metal and Dielectric Films

Manufacture of thin film sensors

Optical element

Nano and Microelectronics

Solar battery

high vacuum evaporation coater Technical parameter:

Three Evaporation Source High Vacuum Coater |

Sample stage | Size | Maximum support φ150mm sample |

Function | Rotatable, heating up to 500°C |

Evaporation source | Quantity | Tungsten boat x3 |

Power | Each evaporation source is equipped with an independent power supply; three evaporation sources have a total of three independent power supplies |

Vacuum chamber | Cavity size | φ300x400mm |

Observation window | Front φ100mm |

Cavity material | 304 stainless steel |

Open method | Front door |

Film thickness control (optional) | Crystal-type film thickness measuring instrument, optional multi-channel film thickness controller |

Vacuum system | Foreline pump | Bipolar Rotary Vane Pump |

Exhaust port | KF16 |

Secondary pump | Turbomolecular pump |

Exhaust port | CF160 |

Vacuum measurement | Resistance + Ionization Composite vacuum gauge |

Exhaust rate | Mechanical pump 1.1L/s Molecular pump 600L/s |

Ultimate vacuum | 1.0E-5Pa |

Power supply | AC 220V 50/60Hz |

Pumping rate | Rotary vane pump: 1.1L/S |

Control System | PLC automatic control Operation interface: touch screen + operation panel (touch screen controls deposition process and fast data entry; user friendly PLC software system, can be updated via network) |

Other | Supply voltage | AC380V,50Hz |

Overall size | 1000mm X 800mm X 1500mm |

Total power | 5kW |

Total Weight | 350kg |

Video of Three-source High Vacuum Evaporation Coater: