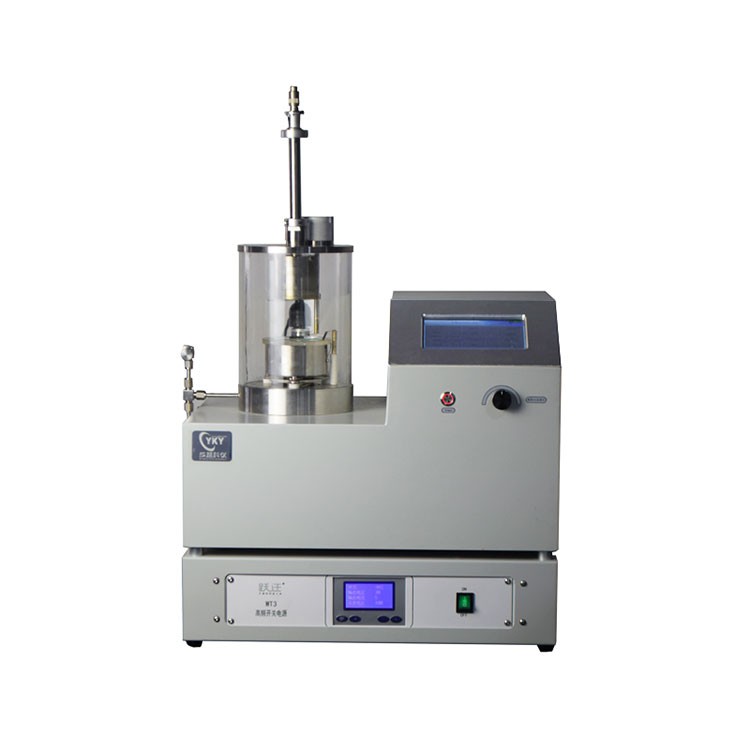

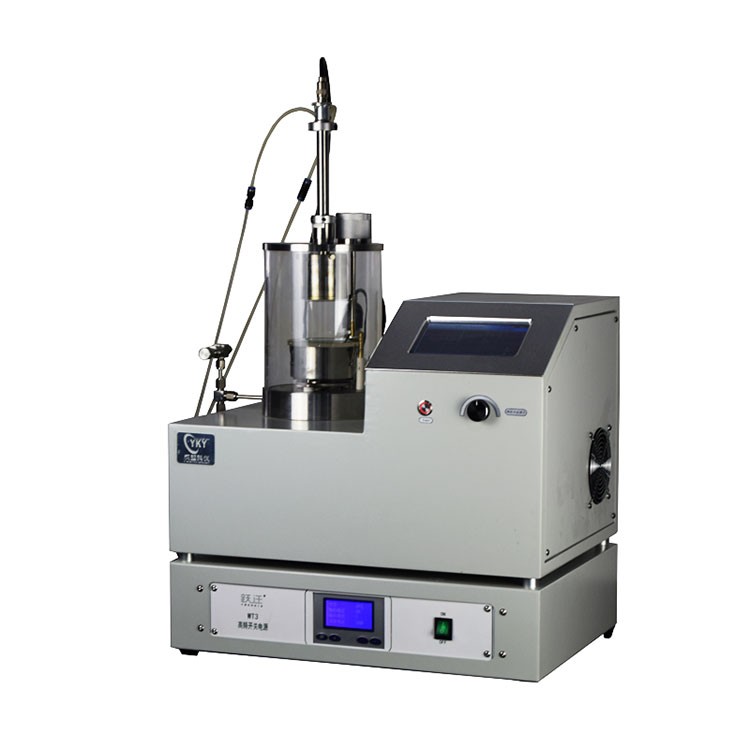

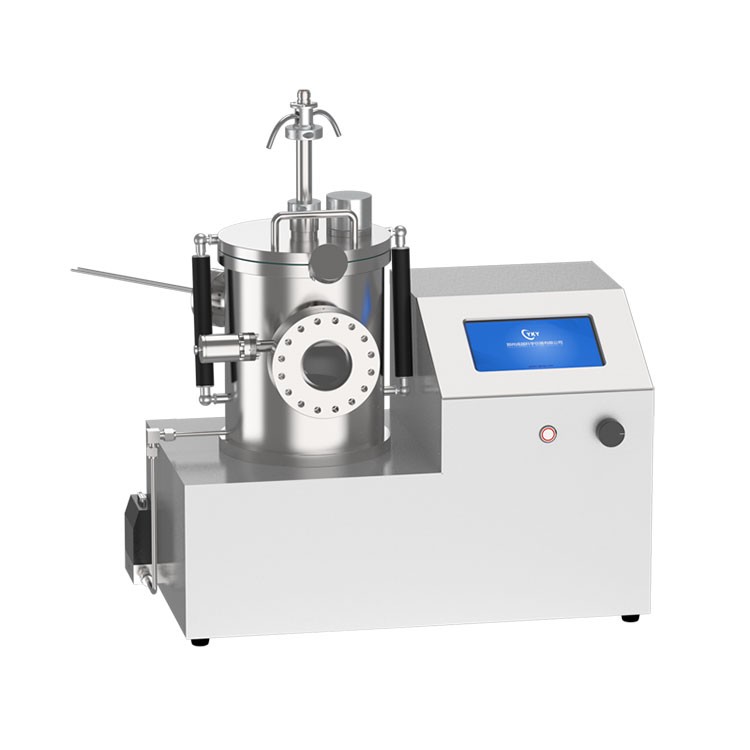

1、 Sputtering power supply:DC power supply 300W;maximum output voltage 600V,limited current output 500mA 2、 Magnetron target:2 inch balance target,magnetic coupling baffle; 3、 Bias power supply: output voltage <1000V, type: high-frequency pulse DC power supply 4、 Suitable target material: φ50mm x 3mm in thickness 5、 Cavity size :outside diameter194,inside diameter186mm x height 230mm 6、 Cavity material: 304 stainless steel 7、 Rotating heating sample table:rotate speed 1~20rpm continuously adjustable;maximum heating temperature 500℃,the lowest recommended heating rate 10℃/min,the highest recommended heating rate 20℃/min. 8、 Cooling mode :magnetic target and molecular pump require circulating water cooler 9、 Water-cooling machine:the tank volume 9L,flow rate 10L/min 10、 Gas supply system:mass flow meter, type of gas Argon,flow 1~30sccm(customizable) 11、 Accuracy of flow meter :±1.5% measuring range 12、 The air pumping interface of the vacuum chamber is KF25 13、 Air intake interface is 1/4 inch double ferrule joint 14、 Touch screen is 7inch color touch screen 15、 Adjustable sputtering current,sputtering safety current value and safety vacuum value can be set; 16、 safety protection: over current, vacuum is too low automatically cut off the sputtering current 17、 Ultimate vacuum:5E-4Pa(matching molecular pump); 18、 Vacuum measurement is Parana vacuum gauge ,the range is:1~105Pa |