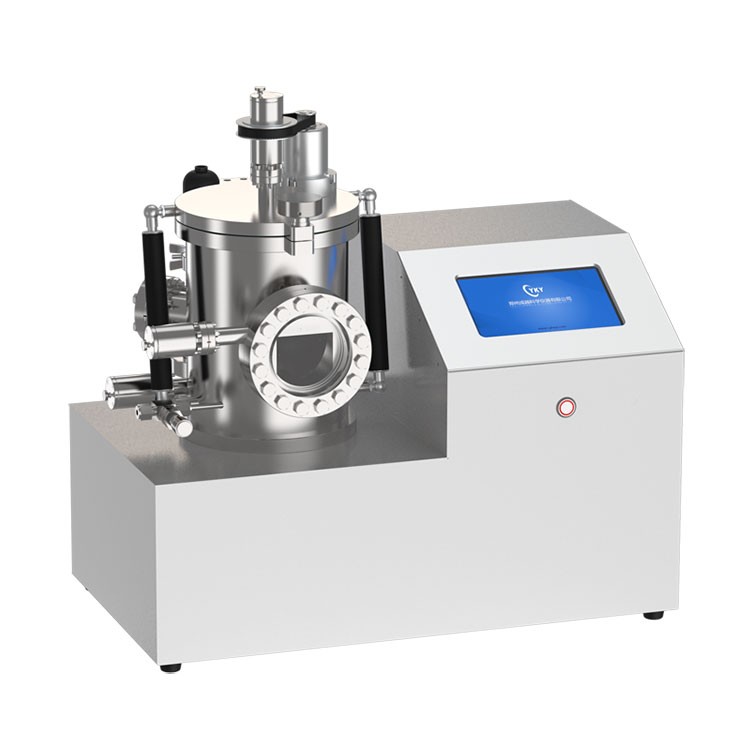

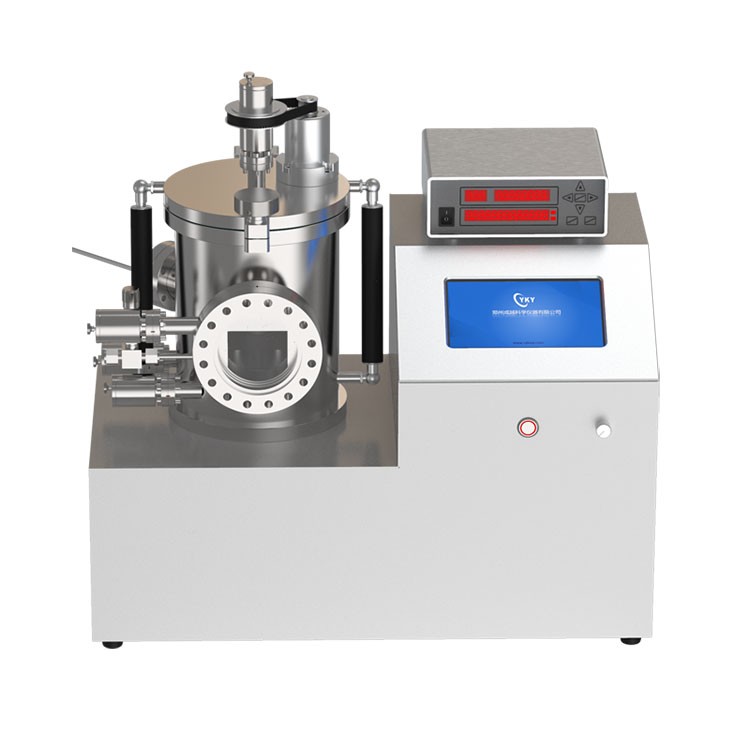

1、 Number of evaporation sources: 2, each evaporation source is equipped with baffle; 2、 Evaporation source voltage: 10V 3、 The evaporation current is continuously adjustable from 0 to 100A 4、 With two tungsten boat, two tungsten basket; 5、 Stainless steel water-cooled rotating upper sample platform, diameter is 100mm, rotating speed 1~20rpm continuously adjustable; 6、 The distance between the sample platform and the evaporation source is 300mm; 7、 The water cooling interface of the sample table is φ6mm quick plug connector, which needs to be equipped with circulating water cooler. 8、 The vacuum cavity is a stainless steel cavity with an outside diameter of 195mm , an inside diameter 185mm and a height of 350mm; 9、 Quartz observation window with baffle, size ofφ60mm 10、 The air pumping interface of the vacuum chamber is KF40; 11、 Air intake interface is 1/4 inch double ferrule joint ,stainless steel fine-tuning valve is provided by default to adjust the air intake; 12、 Touch screen is 7inch color touch screen; 13、 Adjustable sputtering current ,sputtering safety current value and safety vacuum value can be set; 14、 safety protection: over current, vacuum is too low automatically cut off the sputtering current; 15、 Ultimate vacuum:1Pa(matching double stage rotary vane pump); 16、 Vacuum measurement is Parana vacuum gauge ,the range is:1~105Pa |