Performance specifications and basic configurations |

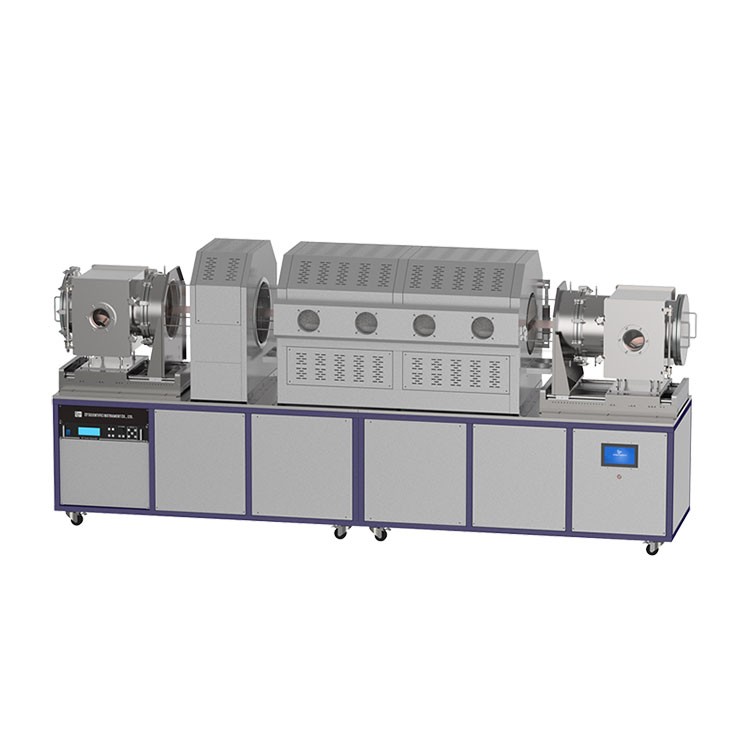

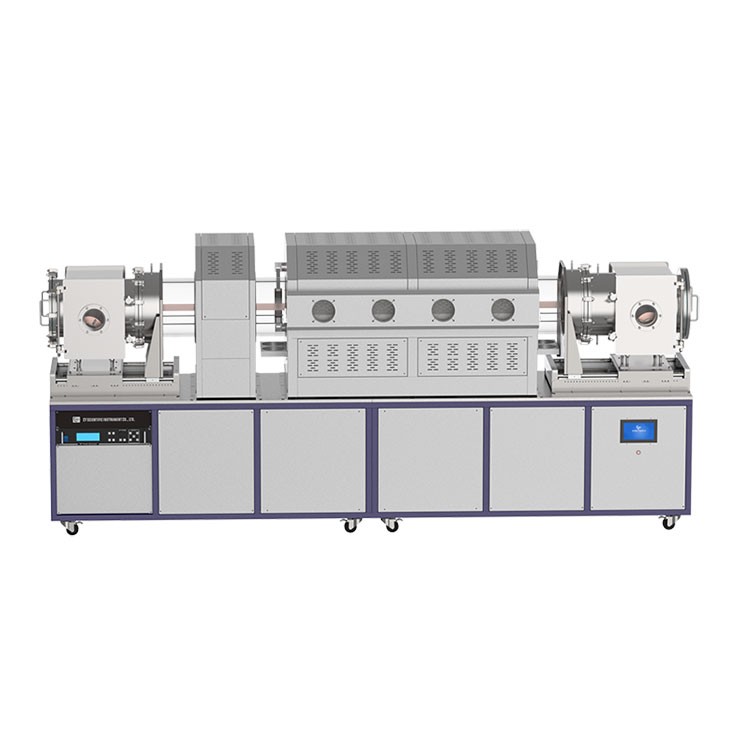

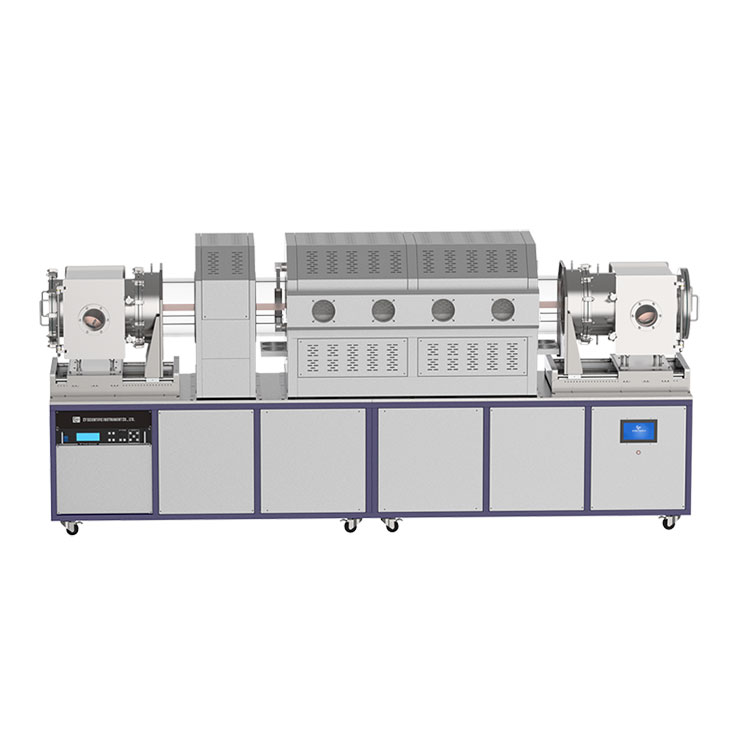

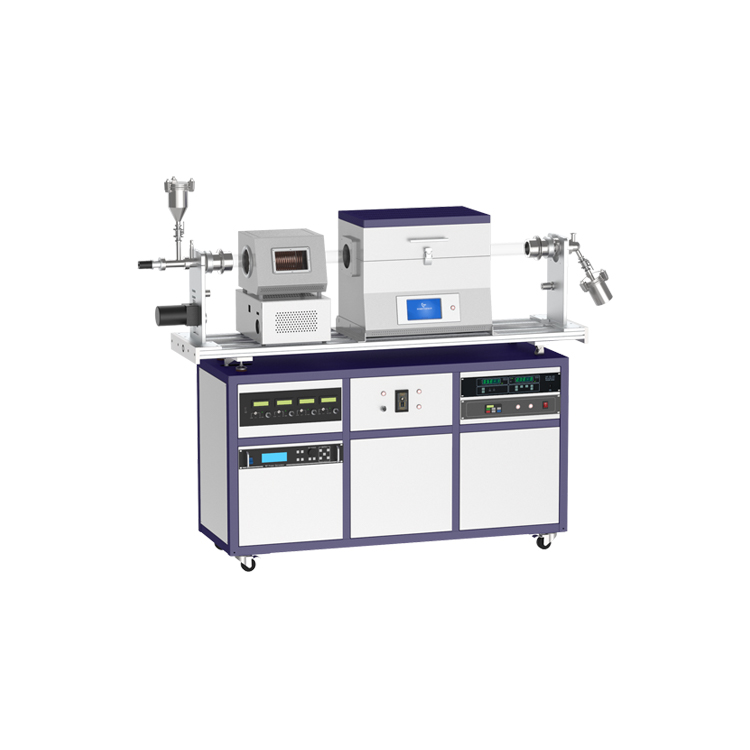

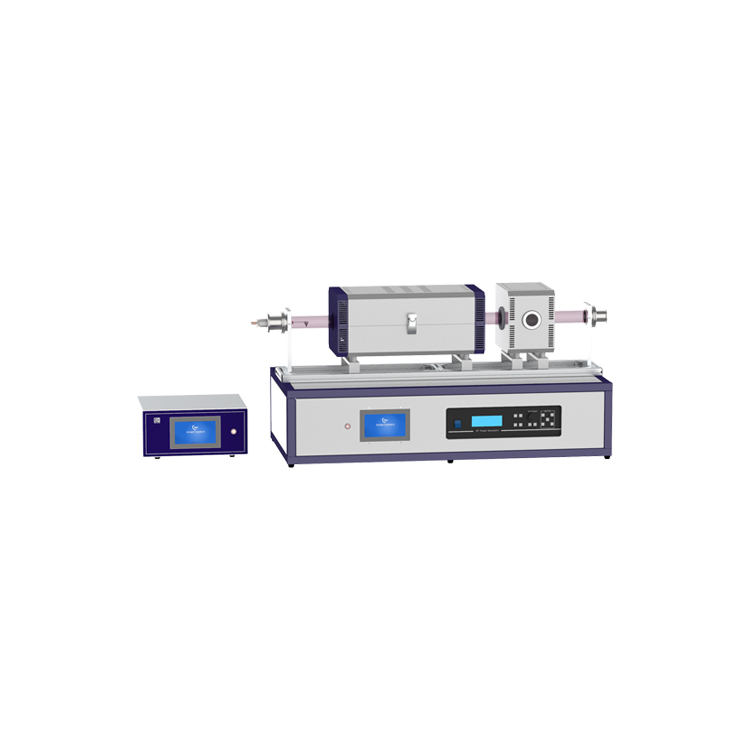

Product name | Roll to roll PEVCD |

Product model | CY-OTF-1200X-III-PE300-RR |

1000W Plasma source | ● Output power:50-1000W Maximum adjustable ±1%

● RF rate: 13.56MHz,stability±0.005%

● dB:≤55DB

● Cooling mode :forced air cooling

● Input power:1KW AC 220V |

Three proton flow meter control system | ● Voltage:AC220V/50Hz

● Power:23W

● PLC touch screen control

● Size of mixing tank:φ80*120mm

●Operating temperature:5~45℃

● Maximum pressure: 3x106 Pa

● Precision : ±1.5% FS

● Linear: ±(0.5-1.5)%F.S.

● Repeated accuracy: ±0.2%F.S.

● Range of flow:

● The first path : 1~50 SCCM (Methane calibration)

● The second path: 1~200 SCCM (Hydrogen calibration)

● The third path: 1~200 SCCM (Argon calibration)

Other options are available for gas type calibration according to customer requirements |

Vacuum measure unit | ●Model:PCG-800

● Indication range:3.8E-5 to 1125torr

Precision:

● 5×10-4 … 1×10-3 mbar (N2) % of reading ±50

● 1×10-3 … 100 mbar (N2) % of reading ±15

● 100 … 950 mbar % of reading ±5

● 950 … 1050 mbar % of reading ±2.5 |

Low vacuum unit | ● It is composed of double-rotating mechanical pump, double-layer vertical oil mist filter (PE material), resistance vacuum gauge and connecting pipe joint ● Suction rate of vacuum pump≥4.4L/s

● Limit vacuum degree 10-1Pa

●Vacuum gauge measuring range 10-1Pa-105 Pa |

Reel-to-reel sealing devices for copper foil | · ● Coil to coil winding and unwinding mechanism is used to move copper foil in and out of the material, and the moving speed of copper foil is adjustable from 1-400mm/min.

● Configure a roll of test copper foil ● The winding and unwinding mechanism is placed in the vacuum chamber at both ends of the tube furnace to ensure that the copper foil can move under sealed growth conditions and achieve large-scale preparation

● A cooling device is set between the winding mechanism and the tubular furnace for rapid cooling of copper foil. |

Product size | About 2400*800*1250mm |

Product weight | About 720kg |

Quality certificate | CE certification is optional for electrical components |

Warranty period | Special note: 1. Consumables such as heating element, quartz tube, sample crucible, etc. are not included. 2. Damage caused by corrosive and acidic gases is not covered by the warranty. |