1. Equipment function

The PLD series equipment is mainly used to grow optical crystals, ferroelectrics, ferromagnets, superconductors and organic compound thin film materials, especially suitable for the growth of complex layered superlattice thin film materials with high melting point, multi-element and containing gas elements.

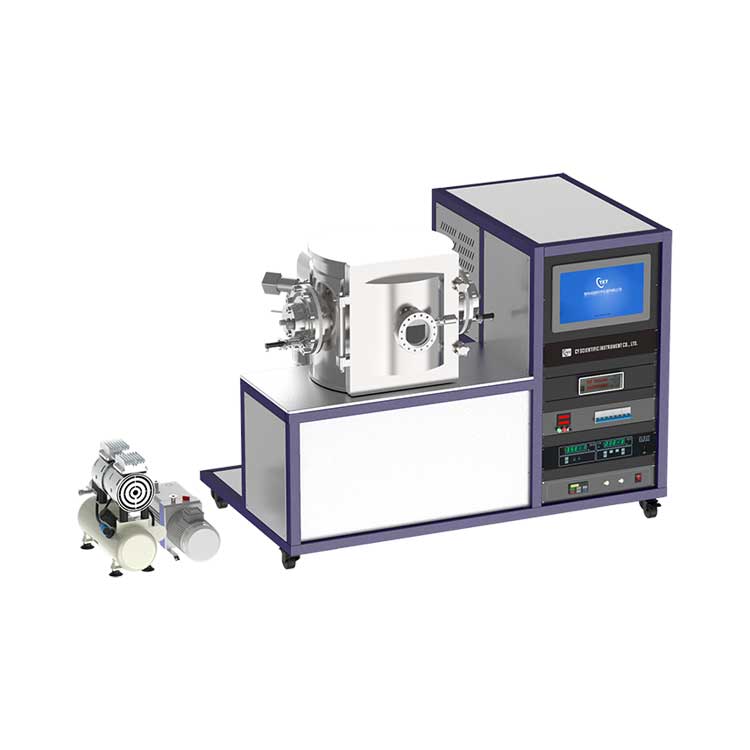

2. Equipment overview

The equipment can be divided into five parts according to the appearance structure: PLD deposition chamber, vacuum measurement system, vacuum pumping system, workbench, and electric control cabinet.

2.1 PLD deposition chamber

Spherical vacuum chamber structure, size Φ450mm, made of 1Cr18Ni9Ti stainless steel material, argon arc welding, surface spray glass shot matte treatment. The vacuum leakage rate is less than 5.0×10-8Pa.I/S. The interface is sealed with a metal gasket or a fluorine rubber ring, and a Φ220 cylinder below the vacuum chamber is installed on the work surface. CF150 knife-edge flange is connected below, and CF150 manual gate valve is connected. Connect the CF150 bypass pipe assembly and connect the 620 molecular pump system. In front of the vacuum chamber, there is a rubber ring sealed door with an observation window, with a diameter of Φ150mm, which is used for sample entry and exit and target material replacement and maintenance. Install the rotating target platform on the left side of the observation window. Install the sample heating table directly opposite the rotating target table. On the same horizontal plane as the rotating target platform, at an angle of 135°, two incident observation windows with a diameter of Φ100mm are arranged. Equipped with infrared and ultraviolet quartz each. Above the vacuum chamber, there is an operation with a diameter of Φ100mm and two test observation windows. There are also two CF35 spare flange ports for equipment upgrades. The vacuum chamber body is equipped with resistance gauge, ionization gauge, KF40 manual pre-pumping angle valve, Φ10 manual vent valve, and CF35 baking lighting electrode.

2.1.1 Rotating target stage

1). Four targets can be installed one time, the size of the target: (i) Φ60mm~Φ25mm;

2). Each target material can realize self-rotation, the speed is 5-50 rpm, continuously adjustable, and controlled by the magnetic coupling mechanism driven by the stepper motor;

3). The target position revolution transposition mechanism is controlled by a magnetic coupling mechanism driven by a stepper motor;

4). The target shielding cover shields the three targets, and only one target is exposed for sputtering to form a film at a time to avoid cross-contamination between the targets.

2.1.2 Sample heating stage components

1). Substrate size: Φ60mm, can place Φ10mm—Φ60mm samples, adopt mechanical fixing method, and replace the sample by replacing the substrate cover;

2). The maximum temperature of sample heating is 800℃±1℃; it is controlled by thermocouple closed-loop feedback; (Special heaters can be made for oxide research)

3). The substrate can rotate continuously, the speed is 5~50 rpm, which is completed by a stepping motor driving the shaft mechanism;

4). The distance between the target and the substrate can be adjusted at 20-80mm, which is completed by the manual bellows adjustment mechanism outside the moving substrate cavity;

2.1.3 Window accessories

1). Φ100mm quartz glass window (248nm ultraviolet band, for laser incidence)

2). Φ100mm quartz glass window (infrared band)

3). Φ100mm optical glass window

2).1.4 Vacuum pumping system

Equipped with 1 KYKY-160/620 molecular pump,

Equipped with 1 2XZ-8B mechanical pump,

Equipped with 4 Ф40 bellows pipes.

Equipped with 1 air release valve,

Equipped with 2 KF40 with vent solenoid vacuum angle valves,

Equipped with 1 KF40 with inflatable electromagnetic vacuum angle valve,

Equipped with 1 CF150 manual gate valve,

Equipped with 2 CF35 manual angle valves,

Equipped with a set of molecular sieve

2.1.5 Vacuum Path

Equipped with two channels mass flowmeter, N2 gas calibration. 100 SCCM. Enter through the gas mixing tank and through the manual angle valve.

2.1.6 Vacuum measurement system

The vacuum measurement system consists of a measuring gauge and a vacuum gauge. The machine is equipped with direct insertion resistance gauges and metal ionization gauges. Measure the vacuum degree of atmosphere~2x10-5Pa.

2.1.7 Workbench

The workbench is composed of a frame and a hoard. The rack is the skeleton of the equipment, installing the supporting parts. Install gas path, water drain and other components inside.

2.1.8 Electric control cabinet

The electric control cabinet is equipped with a touch screen control unit, a flow display, a substrate heating power supply, an ionization power supply, a 620L molecular pump power supply, and a total power supply.

1). The vacuum control unit is controlled by PLC + touch screen, which controls the vacuum pumping system, sample rotation movement process and lighting system.The touch screen is a 7-inch color screen.

2). The substrate and the organic heating control power supply are composed of conductive SR3 meter. The temperature control accuracy is ±0.5℃. The maximum heating temperature is 800℃.

3). Flow indicator One Belt Two.

4). The ionization power supply is used to clean the substrate, 3KW/1KW.

5). FF160/620 molecular pump power supply controls the start, stop and operation of the molecular pump.

6). At the bottom is the main power area box. When the air switch is closed, the equipment is powered on as a whole. With phase sequence alarm.

3. Main technical parameters:

The ultimate vacuum of PLD deposition chamber | better than 5x10-5Pa |

PLD deposition chamber pumping speed | better than 7x10-4Pa in 40 minutes |

PLD deposition chamber pressure holding | 12 hours <10Pa |

Substrate heating | 800℃ |

Temperature control accuracy | ±0.5℃ |

Movement speed of substrate | 5~50 rpm |

Target position | 4 positions |

Substrate size | Φ60 |

4. Operating environment:

Power supply | ~380V three-phase five-wire power supply system, power <7KW |

Cooling water | circulating volume>15L/Min, cooling water temperature 15℃~30℃ |

Working environment temperature | 10℃~40℃ |

Working environment humidity | 30%~60% |

Floor space | 2000x2500mm |