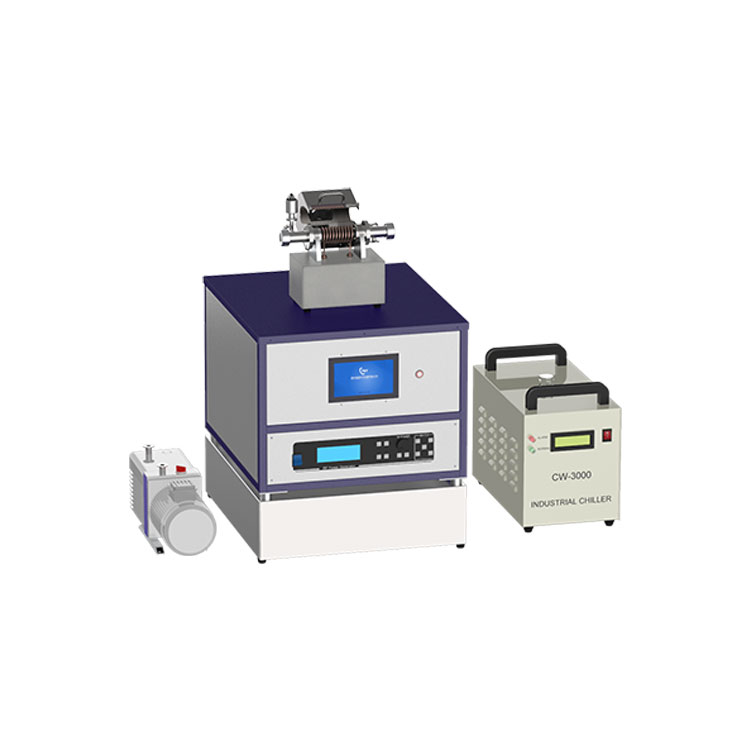

It is suitable for the production of micro-particulate powder in laboratory of universities, research institutes and food, pharmaceutical and chemical enterprises. It is widely applicable to all solutions such as emulsions and suspensions. It is suitable for drying heat-sensitive substances such as biological products, biological pesticides and enzyme preparations, etc. Since the sprayed material is subjected to high temperature and instantaneous heating when sprayed into the mist, these active materials maintain their active ingredients unchanged after drying.

Specifically used in the following fields: beverage spices, pigmented milk, egg products, plant and vegetable extracts, pharmaceutical synthesis, heat-sensitive substances, plastic polymers and resins, aromatics, blood products, ceramics and superconductor biochemical products, dyes, soaps And detergents, food adhesives, oxide bone powder and tooth powder and so on.

Main features of small spray dryer:

●Original imported nozzle, high efficiency.

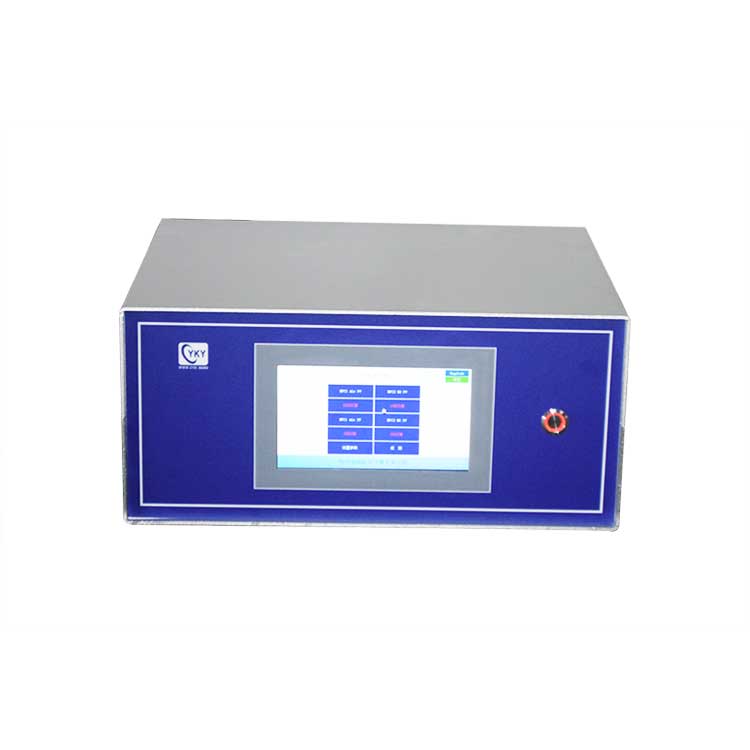

●Color large touch screen operation, combination of automatic control and manual control, Chinese and English panel, LCD display.

● Real-time PID constant temperature control technology, accurate temperature control, heating temperature control accuracy ± 1 ℃.

●The spraying, drying and collecting devices are made of transparent high-quality high-temperature resistant high-borosilicate glass, and the entire spray drying experiment process is visible.

●The atomization structure of the two-fluid spray, made of high-precision 316 stainless steel, the particle diameter of the powder spray is normally distributed, and the fluidity is good.

●The jet is automatically cleared (Nozzle Cleaner) and the frequency is adjustable. When the nozzle is blocked, it will be automatically cleared to ensure the continuity of the experiment.

●The feeding amount can be adjusted by feeding peristaltic pump.

●Special protection function, the fan does not start, the heater cannot start, the fan air volume is adjustable.

●Built-in imported oil-free air compressor, the noise is less than 50db.

●Equipped with air inlet filter to ensure sample purity.

●The particle size of the dried product is uniform, and more than 95% of the dry powder is at the same particle size.

Technical parameters of small spray dryer:

Process processor | 0.05~1 L/H |

Water evaporation capacity | 1.8 L/H |

Inlet air temperature | 30-300℃ |

Typical average particle size range | 2~25 microns |

Parallel flow two-fluid nozzle | Yes |

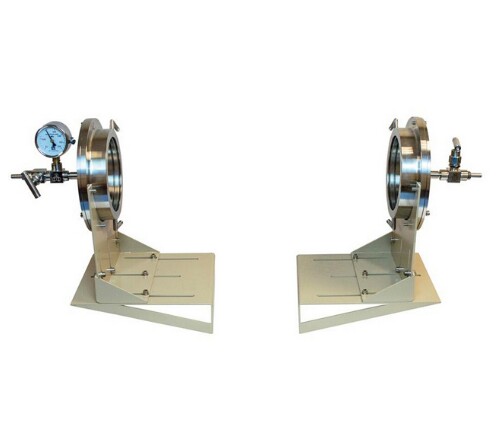

Nitrogen protection system | Optional |

Heating method | Electric heating |

Parts in contact with materials | Borosilicate glass and 316L stainless steel |

Total power | 3.8 kw |

Power supply | 220V/50Hz |

Installation space requirements | 0.8×0.65×1.3 (open type L× W × H m) |

Total weight | 120 kg |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.