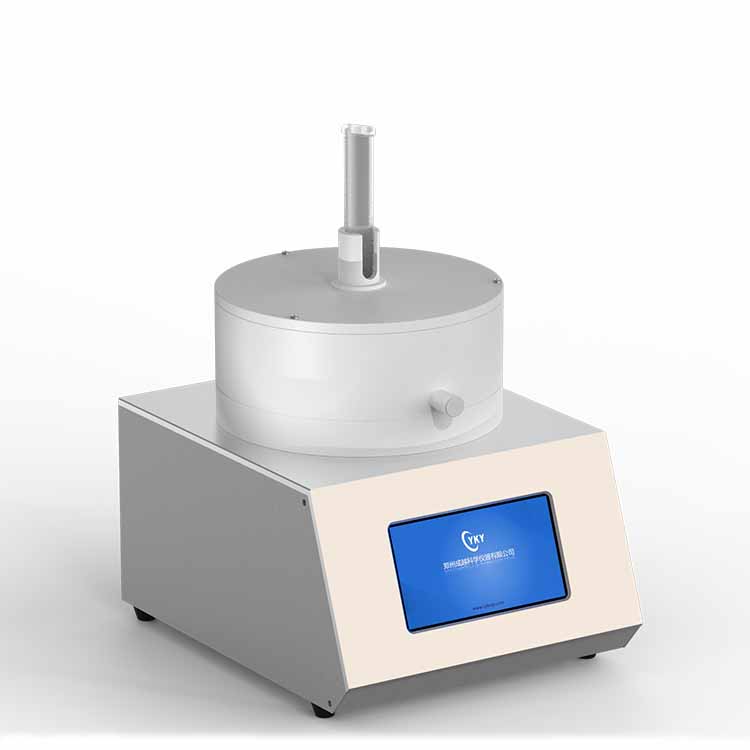

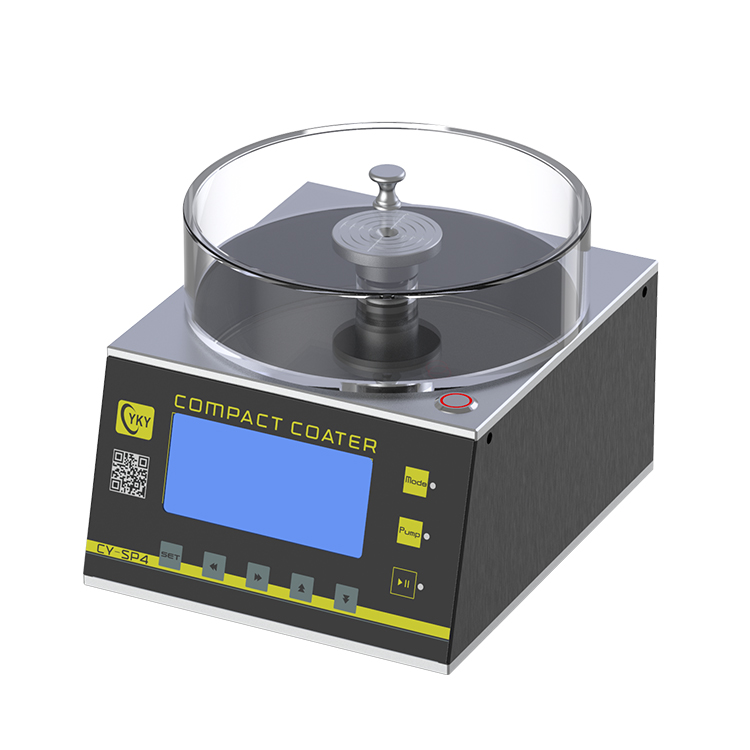

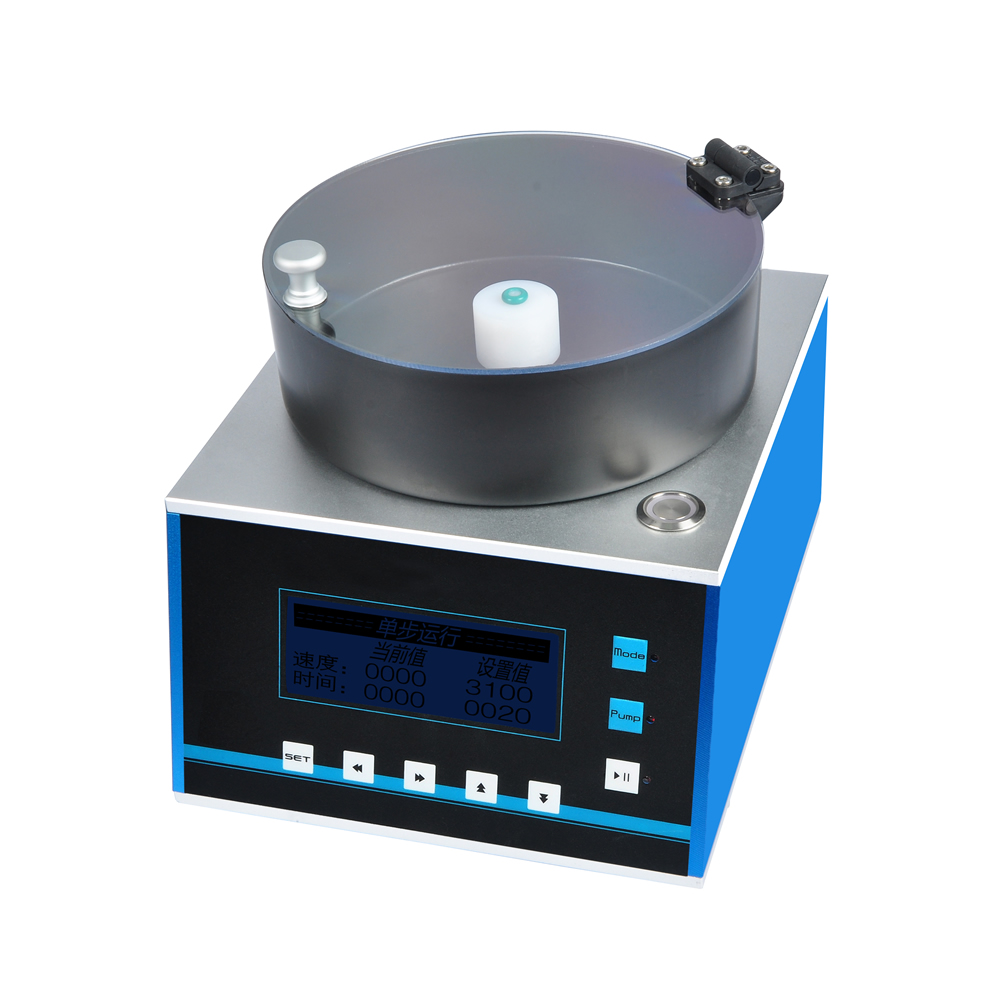

High power program-controlled servo spin coater adopts the stainless steel casing,which is more durable and beautiful than plastic or lacquered metal; use industrial grade 400 watt servo motor system. The leading product in the same class reaches a maximum of 50,000 rpm/s. Rotational acceleration ensures stability and high repeatability of the rotating glue.

High power program-controlled servo spin coater main performance index:

Spin coating program: store up to 100 groups of programs, each group has 100 steps, each step can be accurate to 0.1 seconds

Rotation speed: 0-5,000 rpm (higher speed optional), considering the safety of heavy or large spin coating,it is limited to 5000 rpm

Spin coating acceleration: 0-10,000 rpm / sec (higher optional), considering the safety of heavy or large spin coating, it is limited to 10000 rpm / s

Motor spin coating speed stability error: < ±1rpm

Speed adjustment accuracy and repeatability: 1rpm

Process time setting: 0-3,000 sec/step, time setting accuracy: 0.1sec

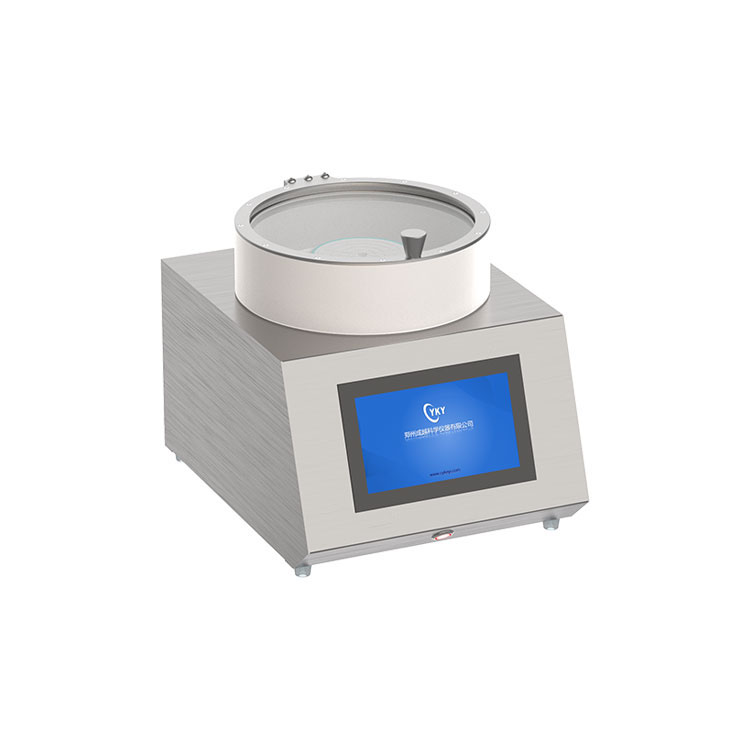

Support wafer size 25px-300mm (12" round crystal)

Spin coating uniformity: < ±3% in the range of 6 inches (need to remove edge 3 mm area to measure)

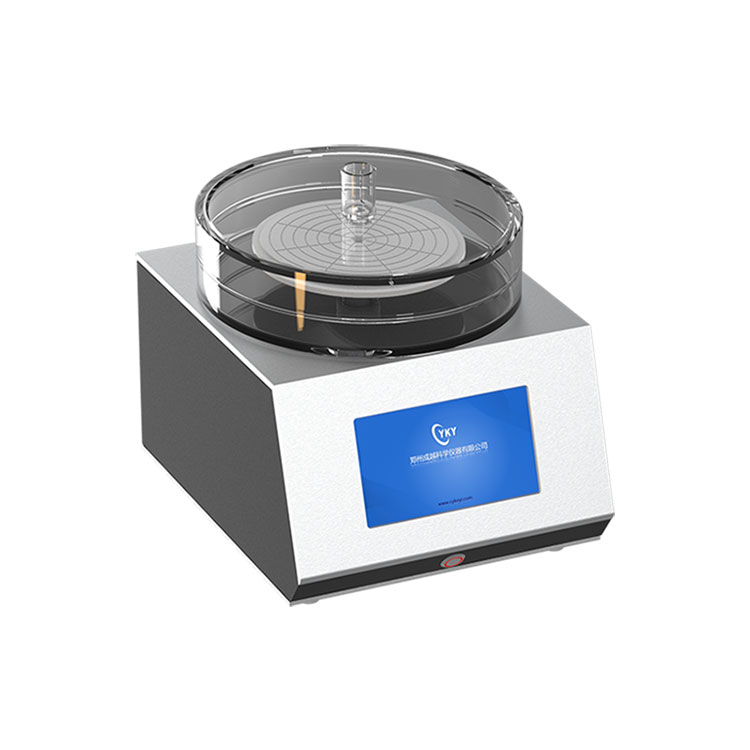

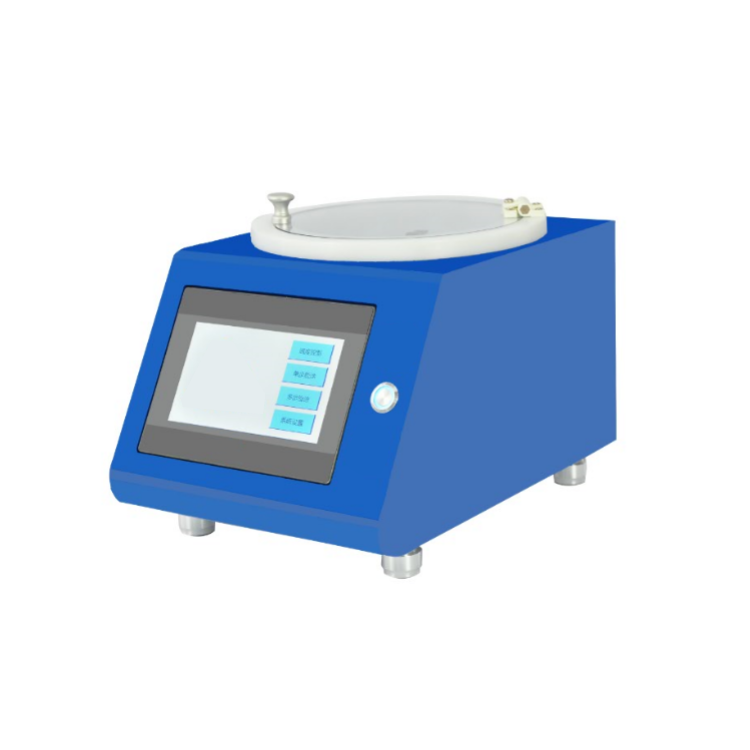

High power program-controlled servo spin coater product feature advantages:

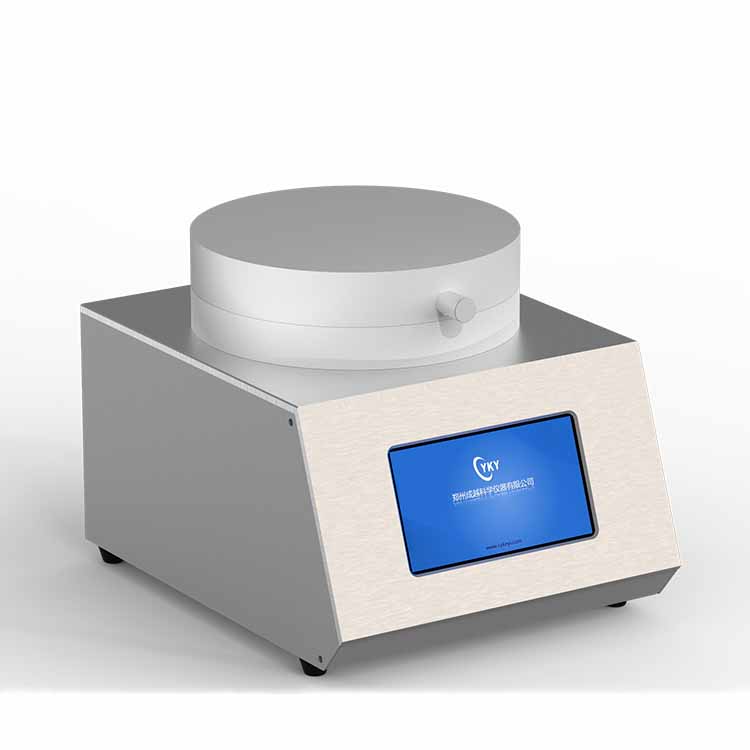

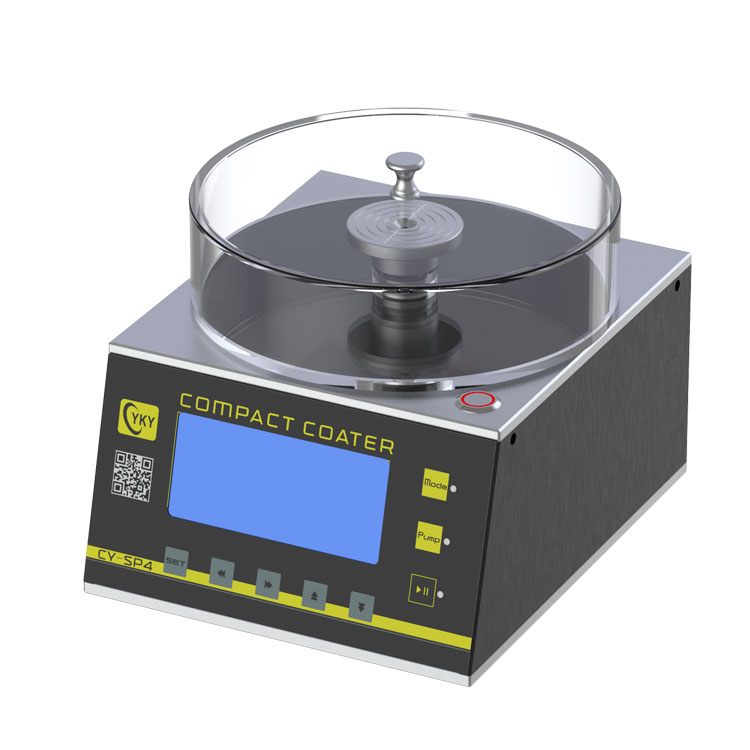

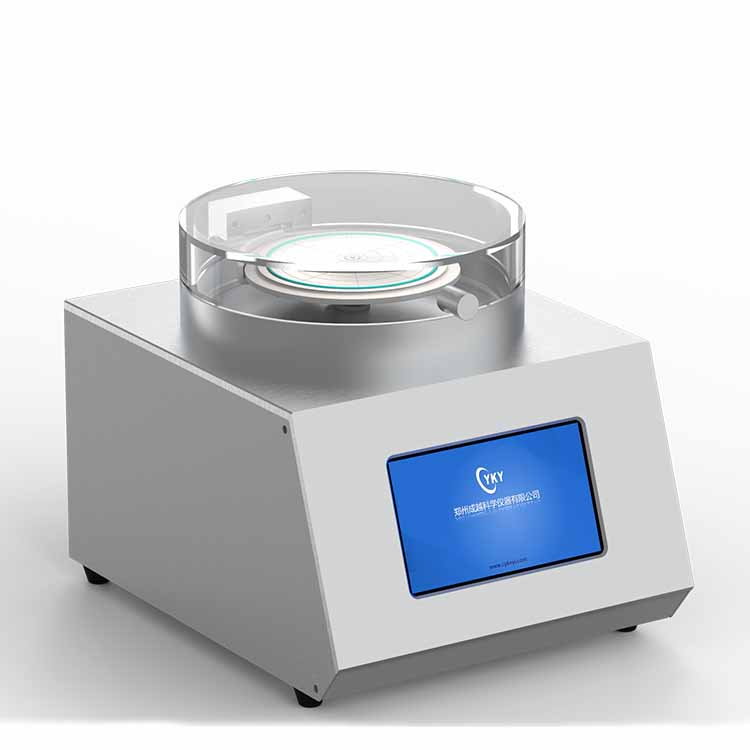

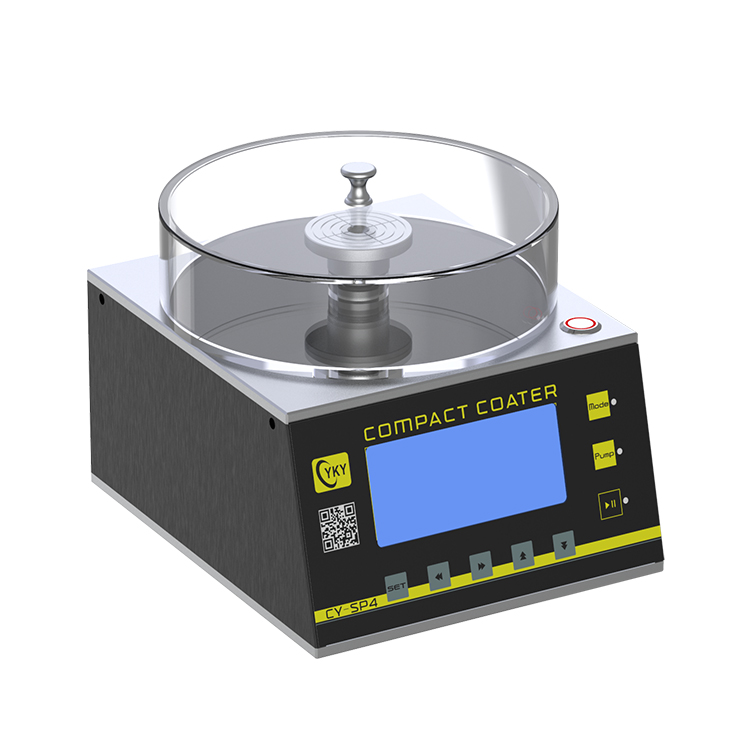

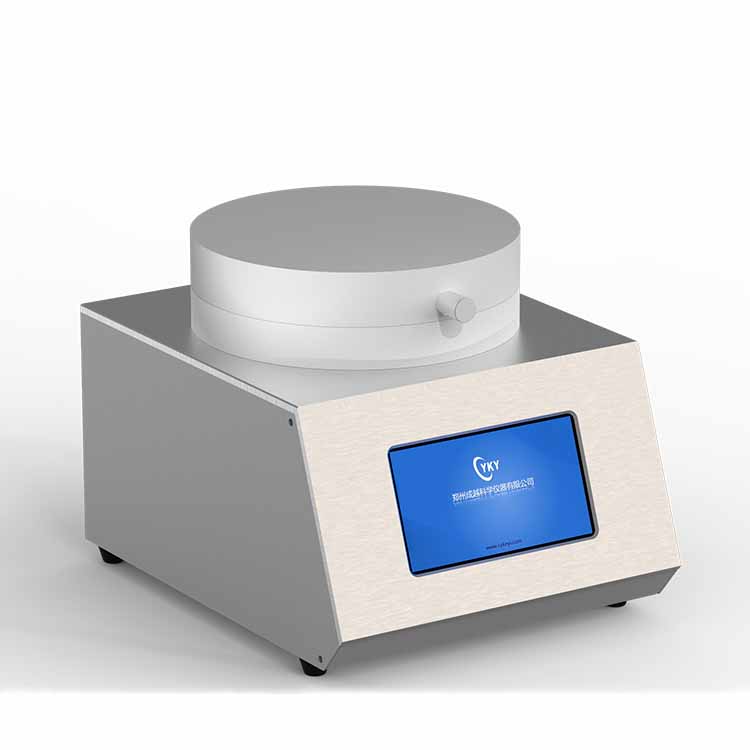

1.The latest in-house compact design reduces the size of the device.

2.7" touch screen control panel operating system, more convenient to operate.

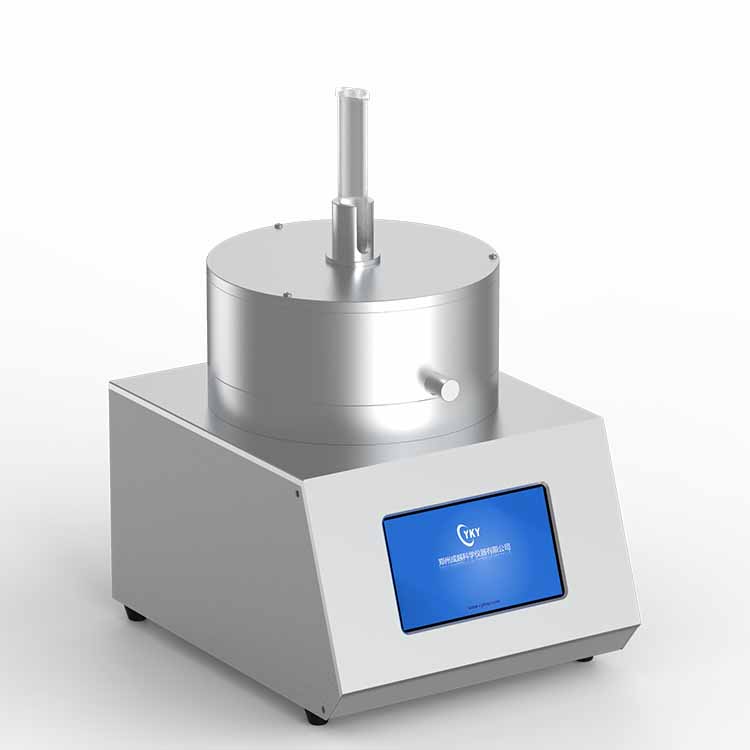

3.Using industrial grade servo motors, the motor design avoids the photoresist and other contaminants into the motor.

4.The body is made of acid and alkali resistant, impact resistant and corrosion resistant stainless steel. It will never rust and is easy to clean.

5.The exhaust and pumping system is located at the bottom of the stage (to facilitate exhaust efficiency and spin coating uniformity).

6.The transparent, chemically resistant sealing cap completely isolates the spillage of the photoresist and effectively isolates the emission of toxic odors during the spin coating operation.

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will not improve or modify any information on the website from time to time without prior notice.