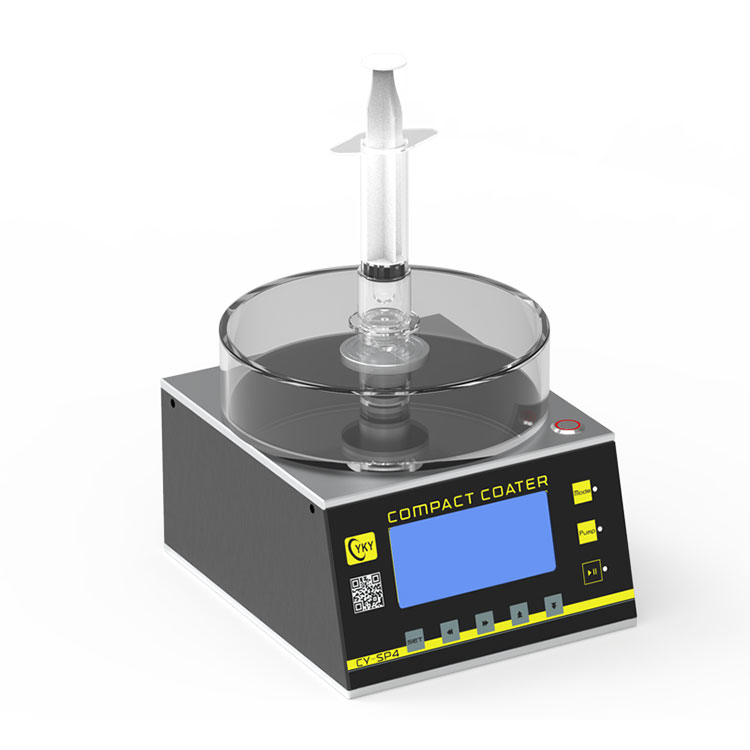

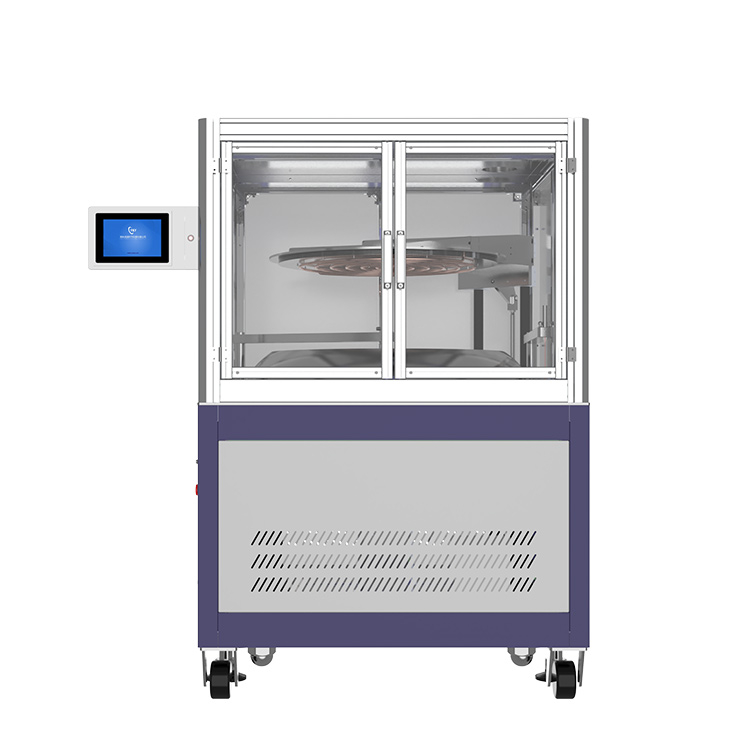

The Four-Nozzle Ultrasonic Spin Coater is a high-end, high-precision semiconductor and micro-nano processing equipment used for coating photoresist or other functional liquids onto substrates. It represents the latest development direction in spin coating technology and is particularly suitable for coating complex structures and non-planar substrates.

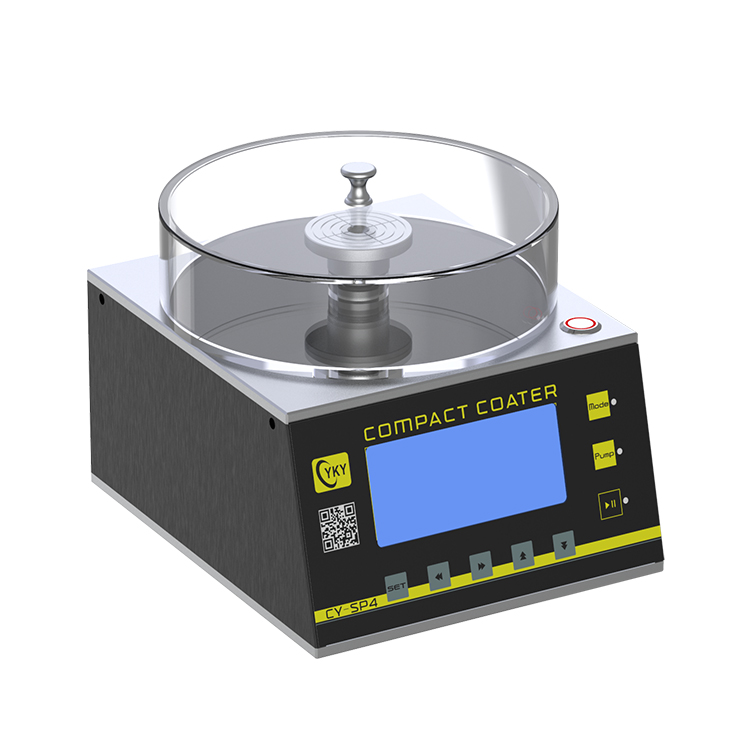

Traditional spin coaters typically have only a fixed drip head or static spray head, covering the substrate with photoresist through central dripping or static spraying, and then relying on the centrifugal force generated by high-speed rotation to spread the colloid evenly.

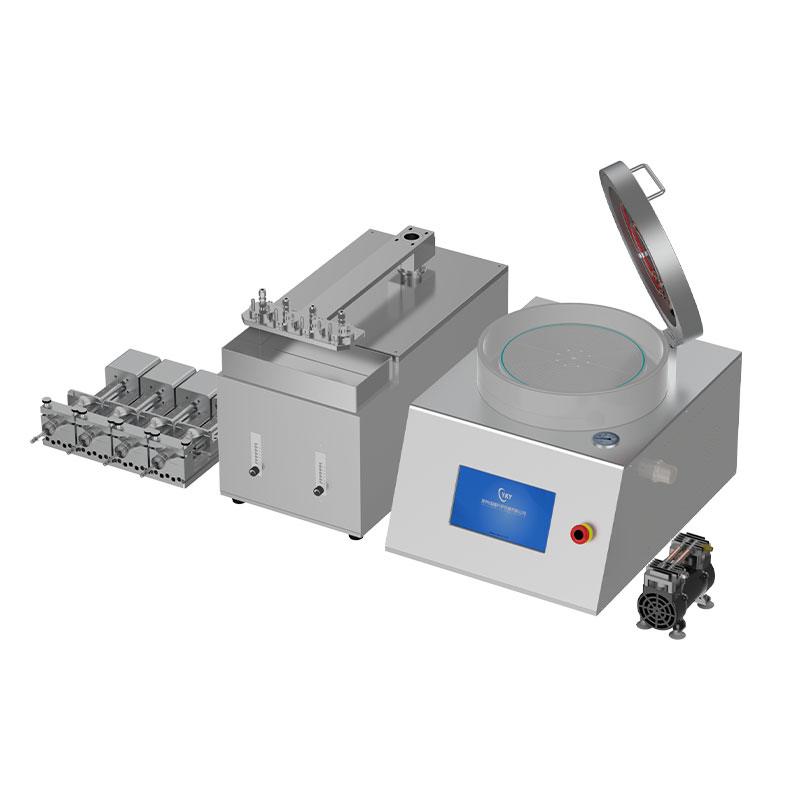

The Four-Nozzle Ultrasonic Spin Coater, however, is a revolutionary design. It integrates the following core components:

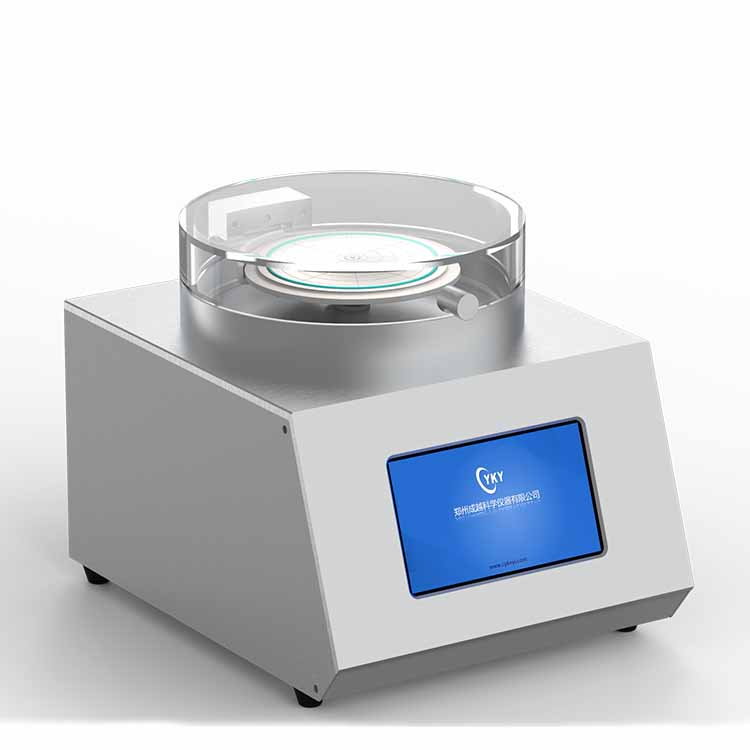

· Four Independent Ultrasonic Piezoelectric Nozzles: This is the origin of its name. Each nozzle is an independent, precision liquid dispensing unit.

· High-Precision Robotic Arm: These four nozzles are mounted on a multi-degree-of-freedom robotic arm, allowing for precise control of the nozzles to perform complex three-dimensional movements above the substrate.

· Ultrasonic Atomization Technology: Utilizes high-frequency ultrasonic vibration to "tear" the liquid into extremely fine and uniform mist-like droplets (typically in the micron diameter range), which are then ejected using a carrier gas.

· Coordinated Control System: A sophisticated software system that synchronously controls the on/off status and flow rate of each nozzle, as well as the movement trajectory of the robotic arm.

I. Working Principle Summary:

It does not simply drip the胶体 onto the center. Instead, like a "3D printer" or "inkjet printer," it uses programmed control of the four nozzles to perform scanning-style spraying on the substrate surface according to preset paths. Each nozzle can operate independently or work cooperatively, achieving unprecedented coating uniformity and flexibility.

II. Core Advantages:

Compared to traditional spin coaters, the Four-Nozzle Ultrasonic Spin Coater possesses overwhelming advantages:

1. Extremely High Uniformity:

2. Excellent Step Coverage and Conformality:

3. Very High Material Utilization Rate:

4. Outstanding Compatibility and Flexibility:

5. Reduced Defects:

III. Application Fields:

Due to its unique technical advantages, the Four-Nozzle Ultrasonic Spin Coater is primarily used in cutting-edge technological fields with extremely high requirements for coating processes:

1. Advanced Semiconductor Manufacturing:

2. MEMS (Micro-Electro-Mechanical Systems):

3. Compound Semiconductors and Power Devices:

4. Photonic Devices and Optical Components:

5. Display Technology:

6. Scientific Research and Frontier Exploration:

IV. Technical Parameters:

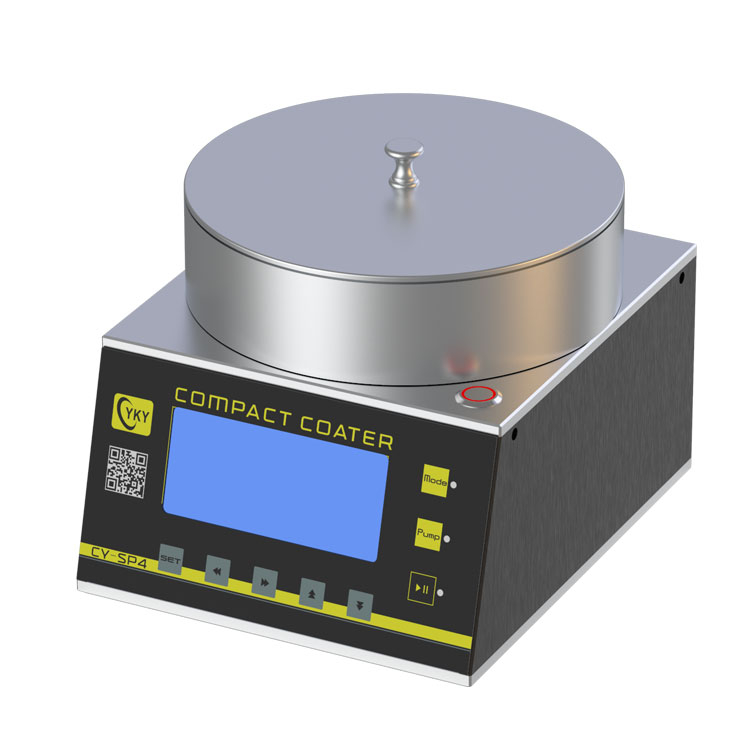

Product Name | Four-Nozzle Ultrasonic Spinning Machine |

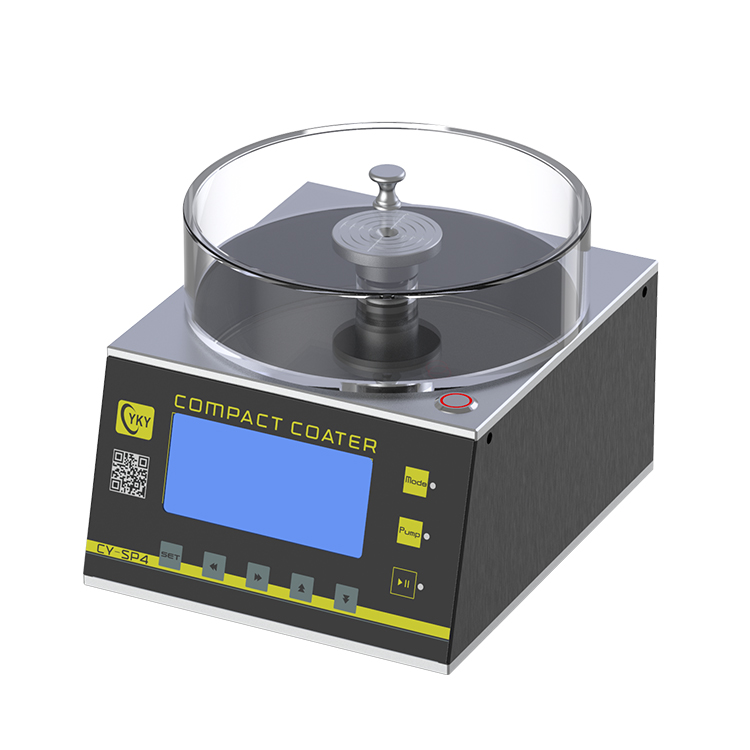

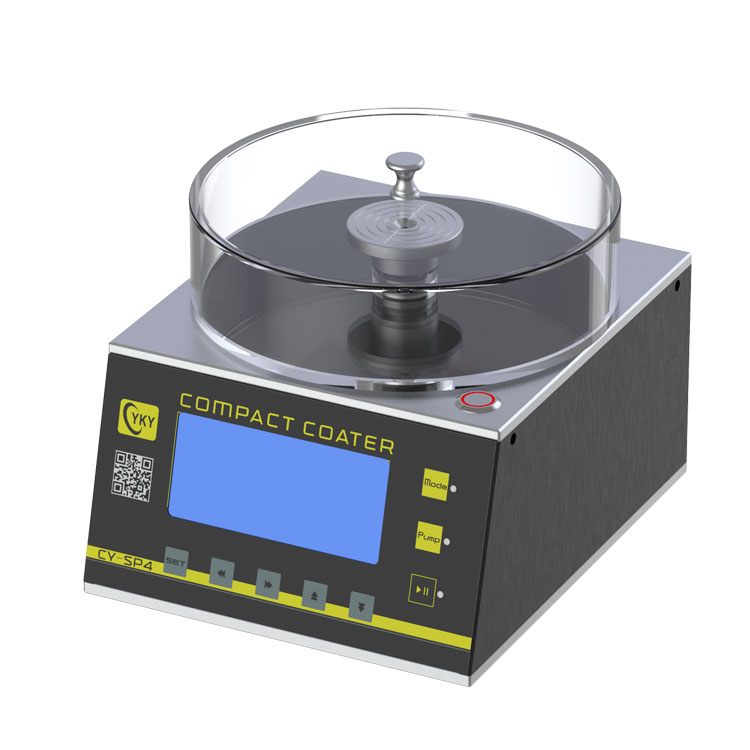

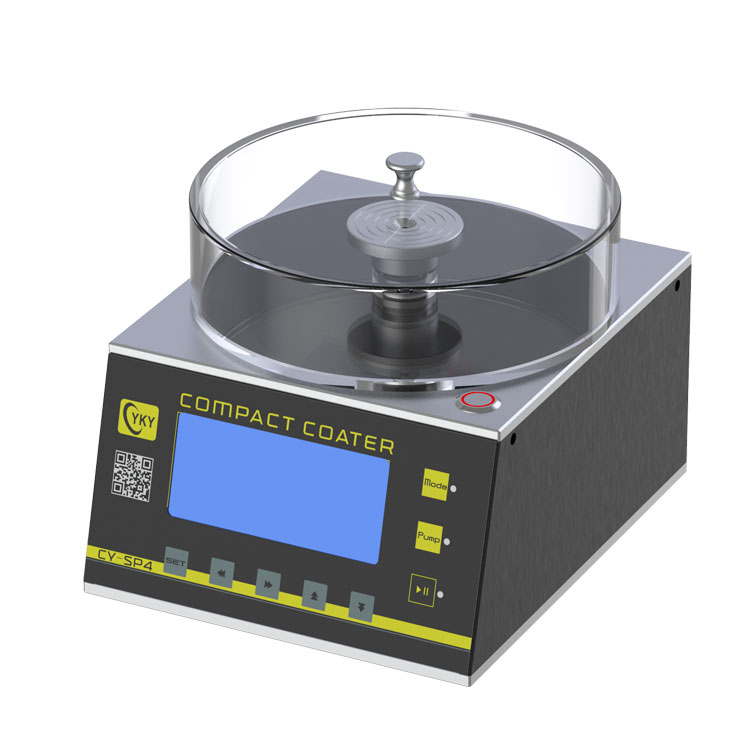

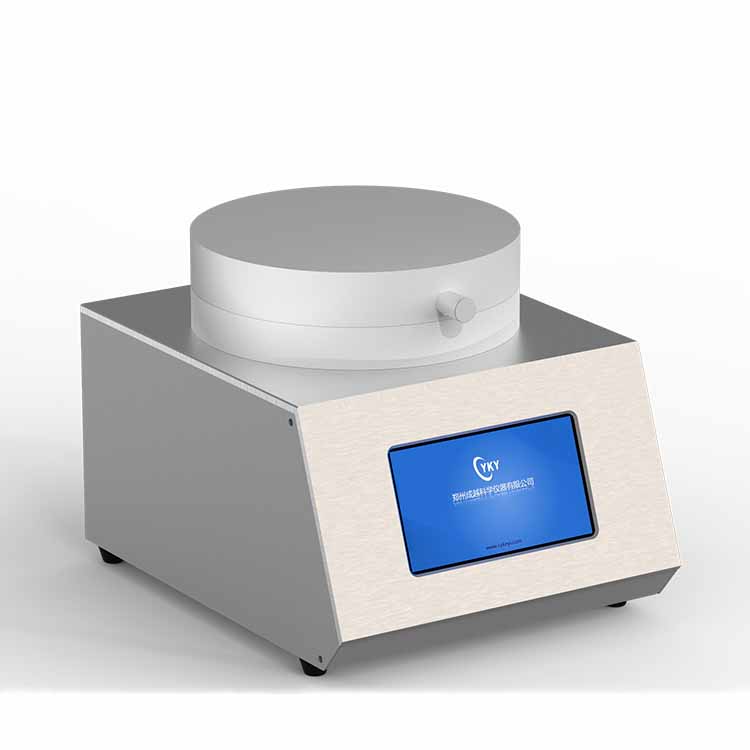

Model | CY-300SS-4 |

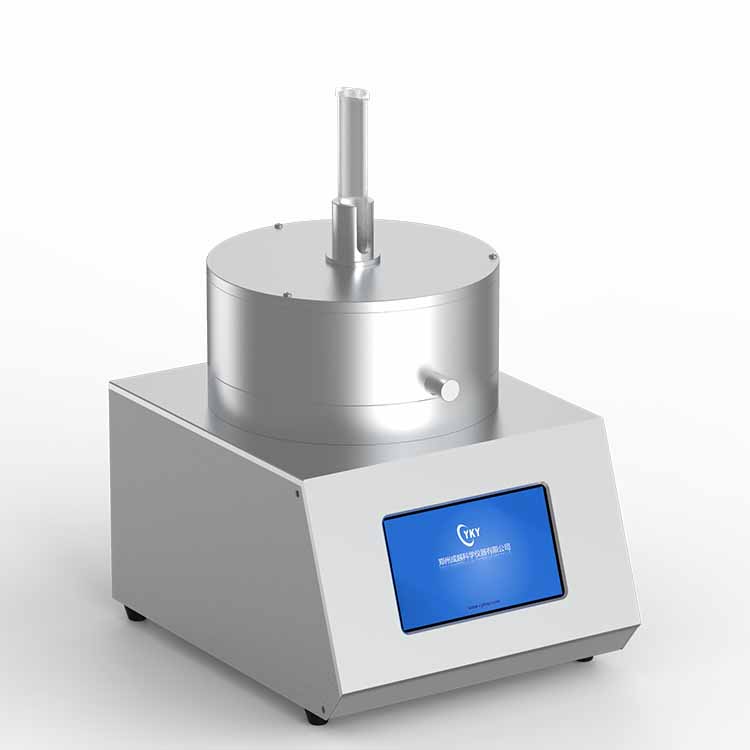

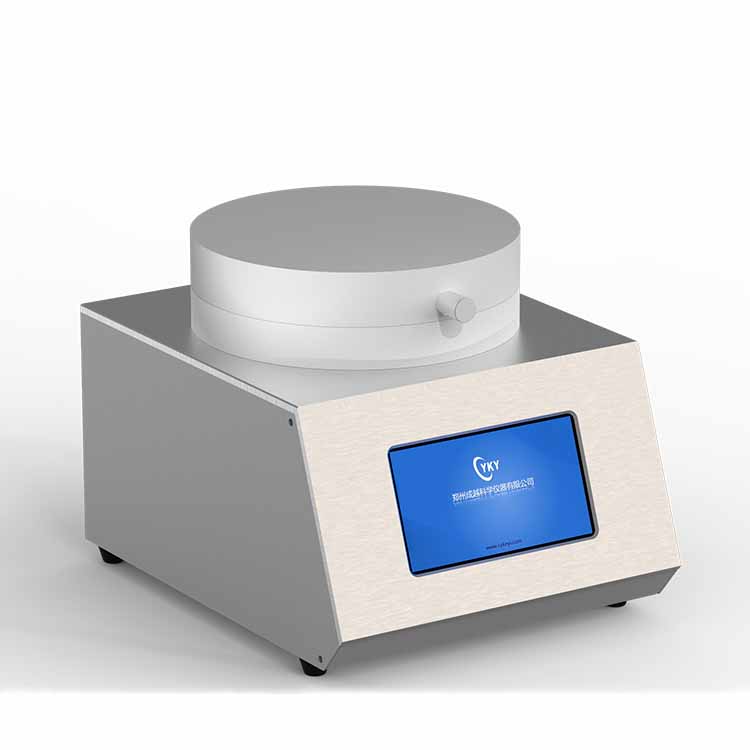

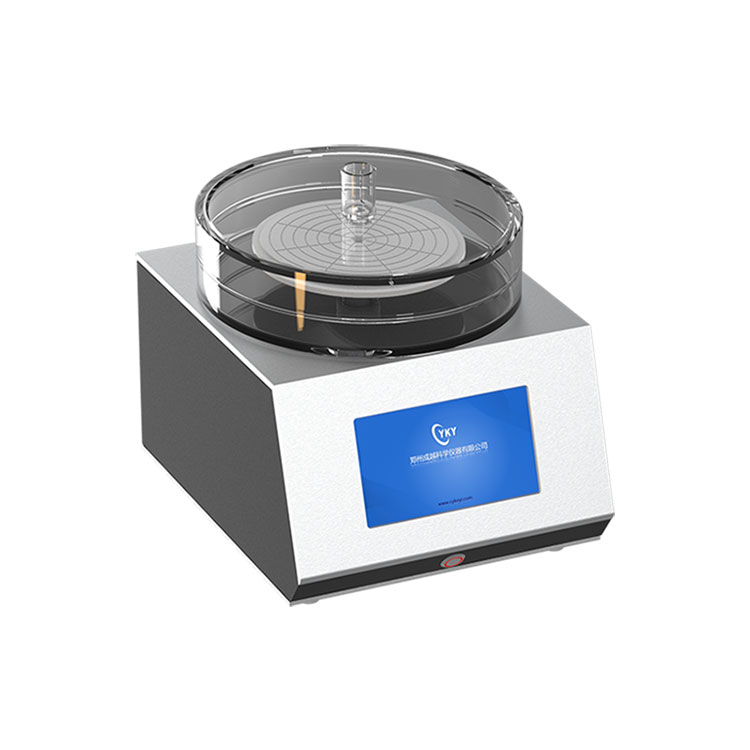

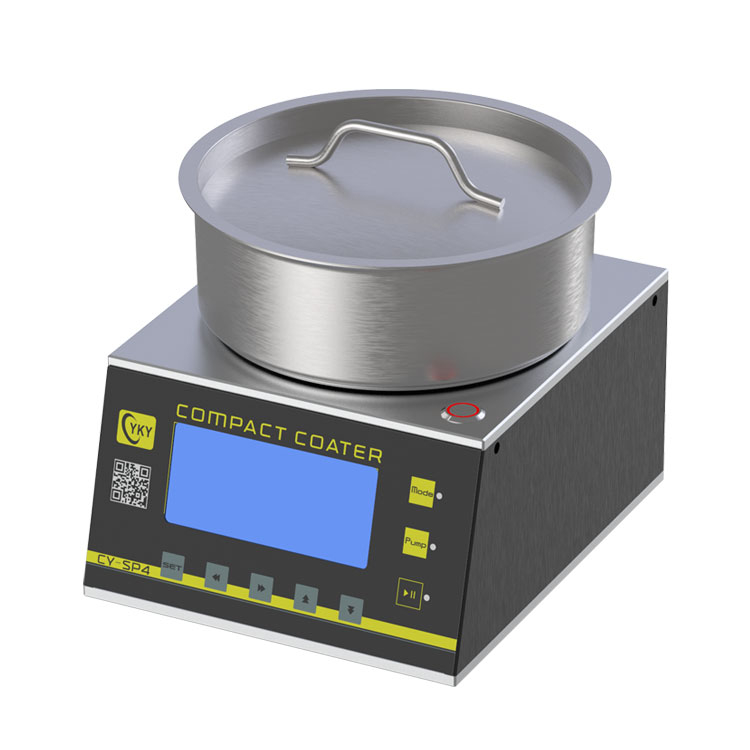

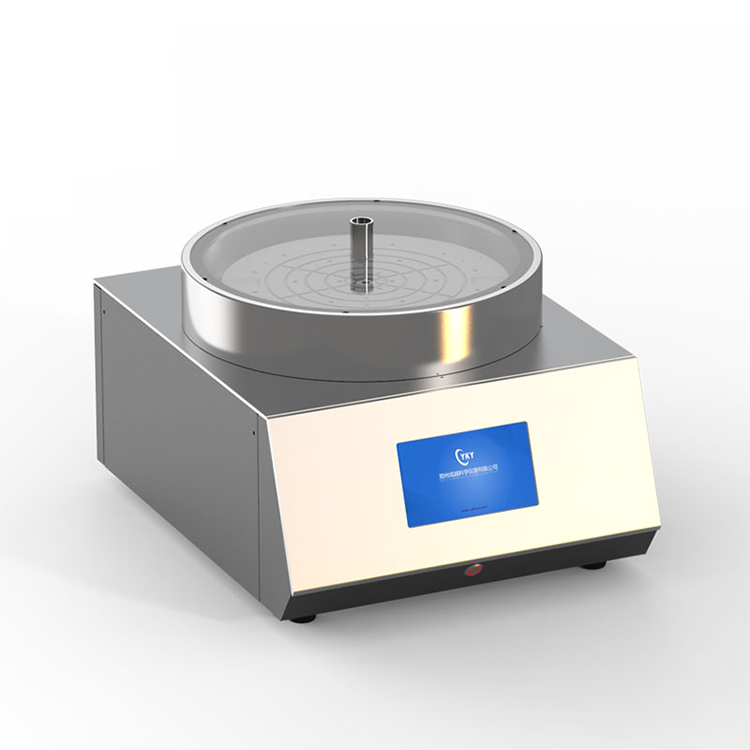

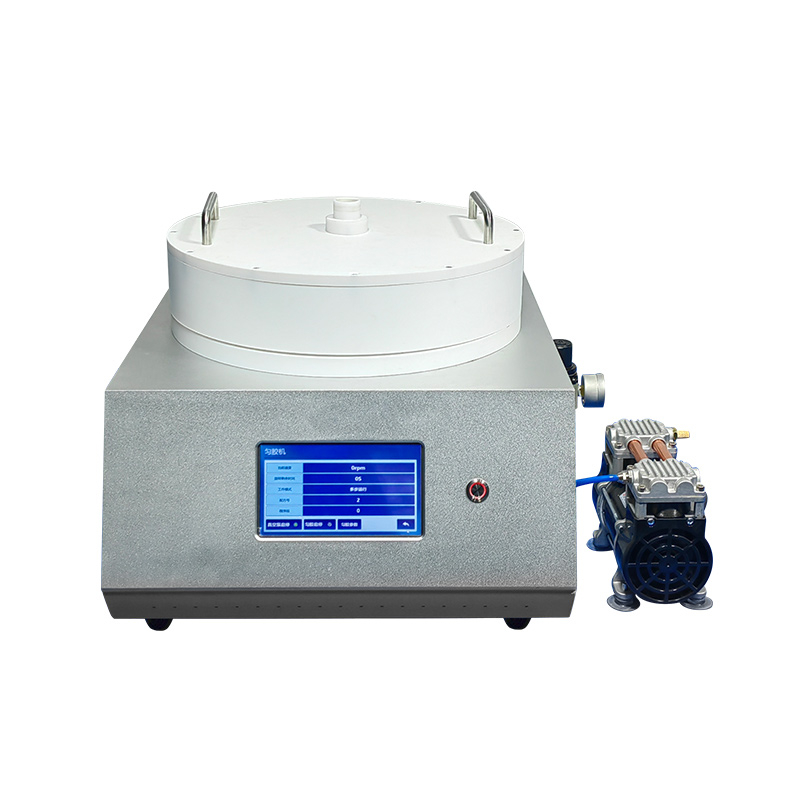

Spin Coater | Wafer Size | 12-inch |

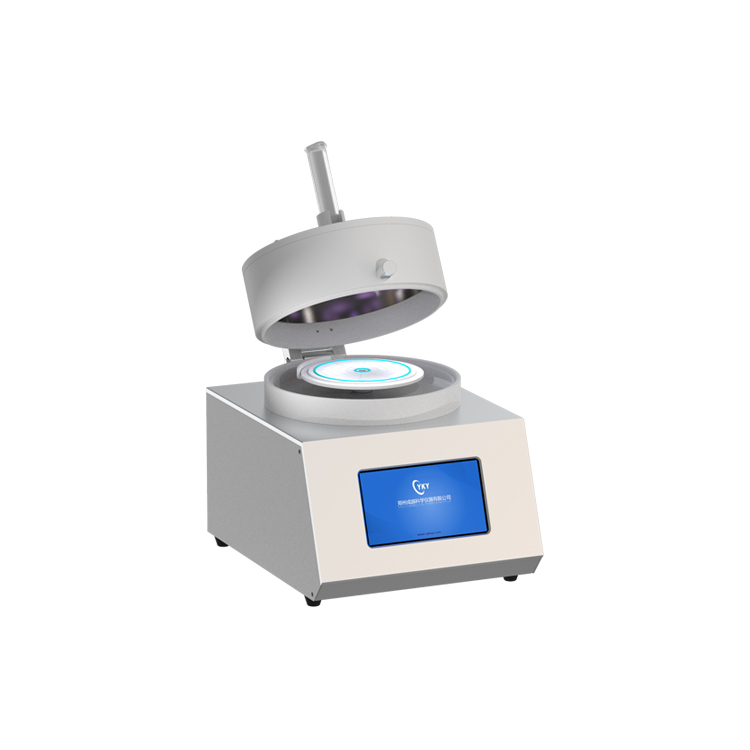

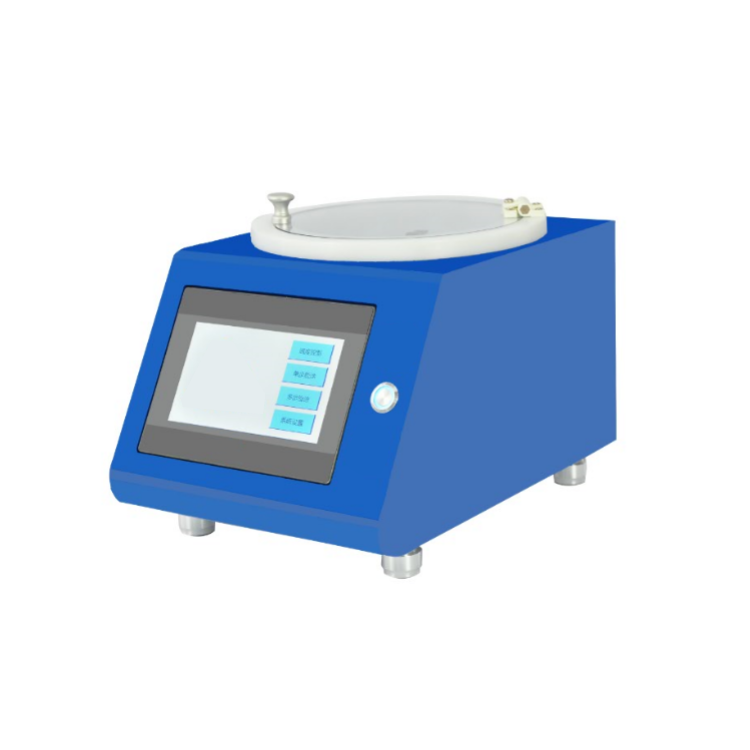

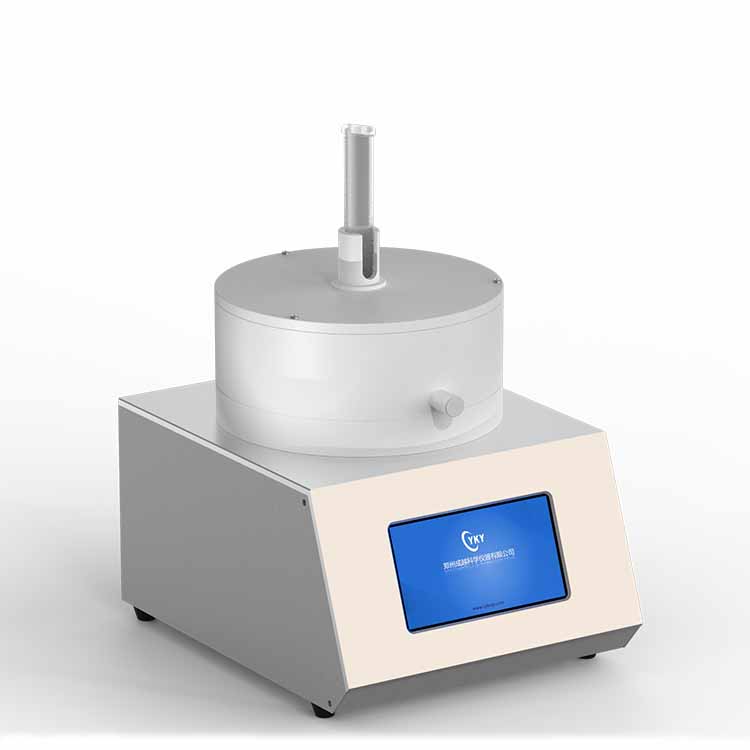

Chamber Material | PTFE |

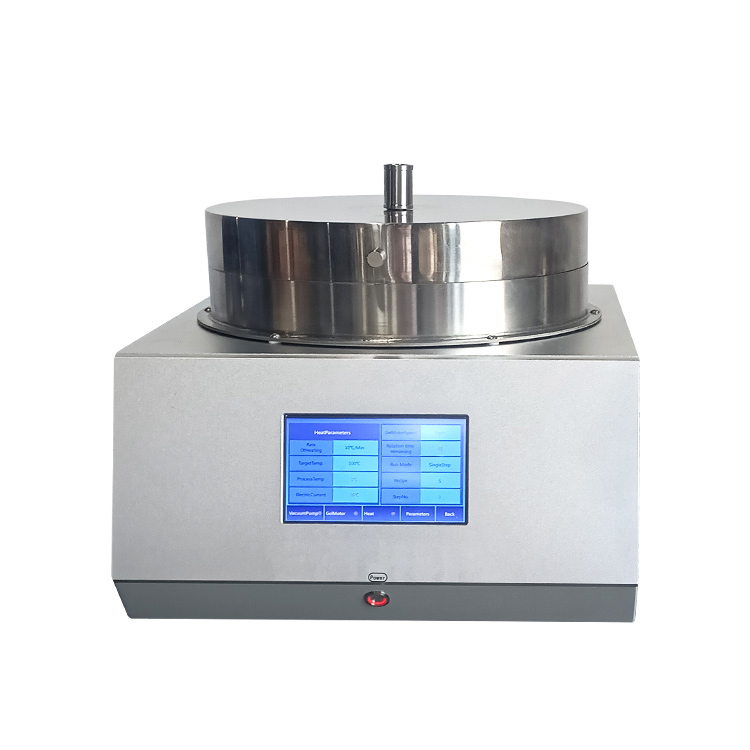

Heating Temperature | ≤200°C (can be used for one hour) |

Temperature Control Accuracy | +/- 0.1°C |

Heating Method | Infrared Heating Element |

Coating Duration | 0-60 sec (Adjustable) |

Coating Thickness | ≤100nm (Depends on your process) |

Rotation Speed | 30~6000rpm adjustable |

Rotation Acceleration | 30~2000rpm/s adjustable |

Speed Resolution | 1rpm |

Max. Single Spin Coating Time | 3000s |

Vacuum Chucks | One 2.5x2.5cm, One 10x10cm |

Temperature Control Method | AIP Intelligent Temperature Control |

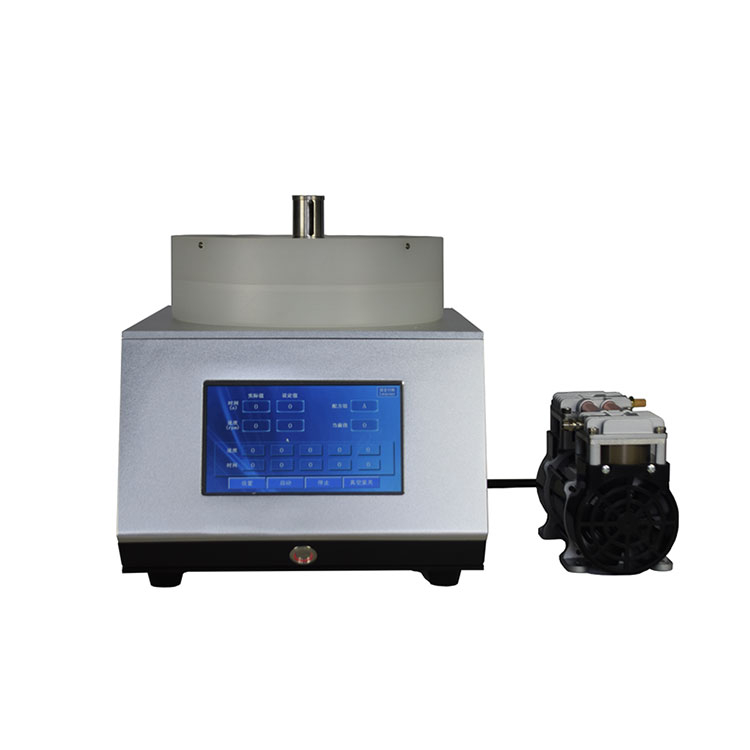

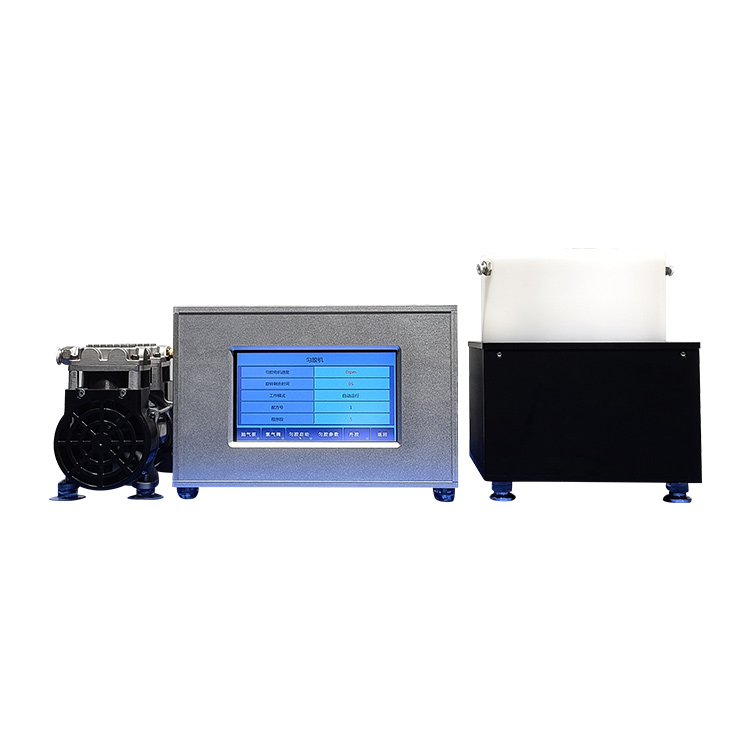

Operation Method | 7-inch HD LCD Touch Screen |

Control Panel | HD Touch Screen PLC. The control panel can set spray, dehydration bake, and temperature control programs. |

Special Pure Mechanical Chucks for Dispenser | One 12-inch (Requires extra customization); One 6-inch (Requires extra customization) |

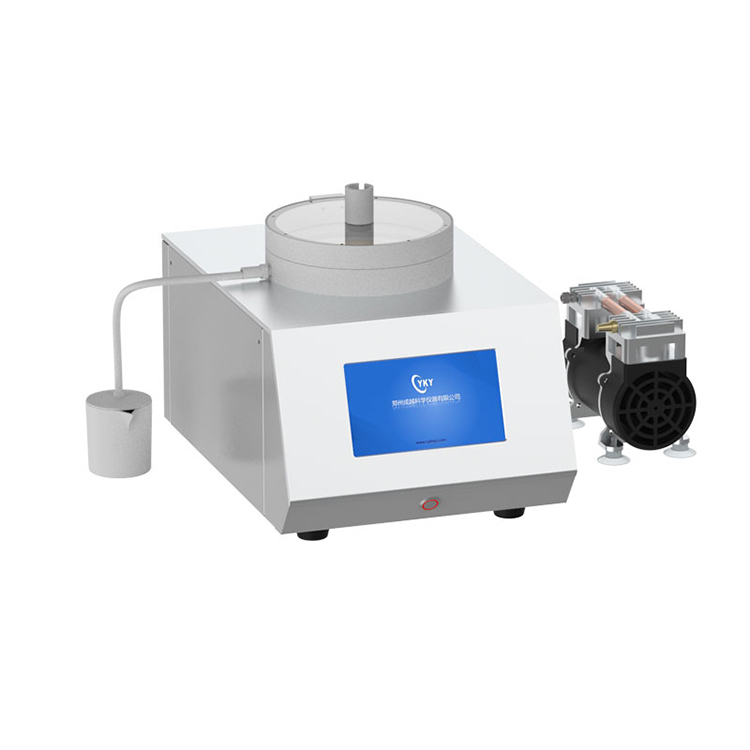

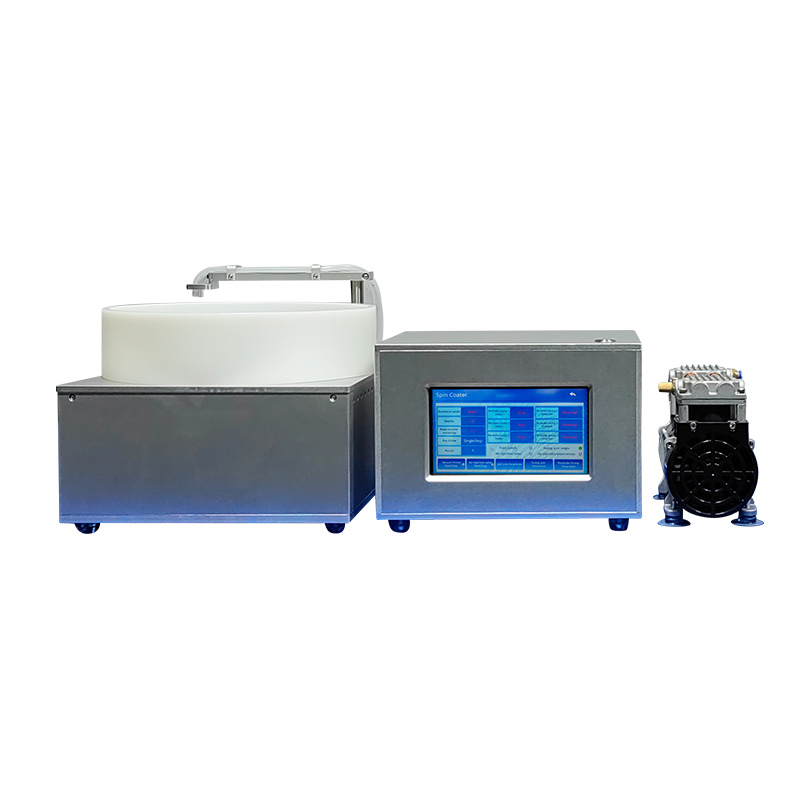

Oil-free Vacuum Pump | Model: AP-2000V

Power: 0.55kw

Minimum Vacuum: -700mmHg; -92Kpa

Max. Air Flow: 200L/min; 12M³/h

Weight: 10kg |

Overall Dimensions | 1200x1000x1050mm |

Ultrasonic System | Quantity | 4 |

Atomizer Head Material | Titanium Alloy |

Frequency | 120kHz |

Power | 130W |

Flow Rate | 0.01-20ml/min |

Droplet Diameter | 20-25µm |

Spray Width | 2-20mm |

Atomizer Head Type | Tapered |

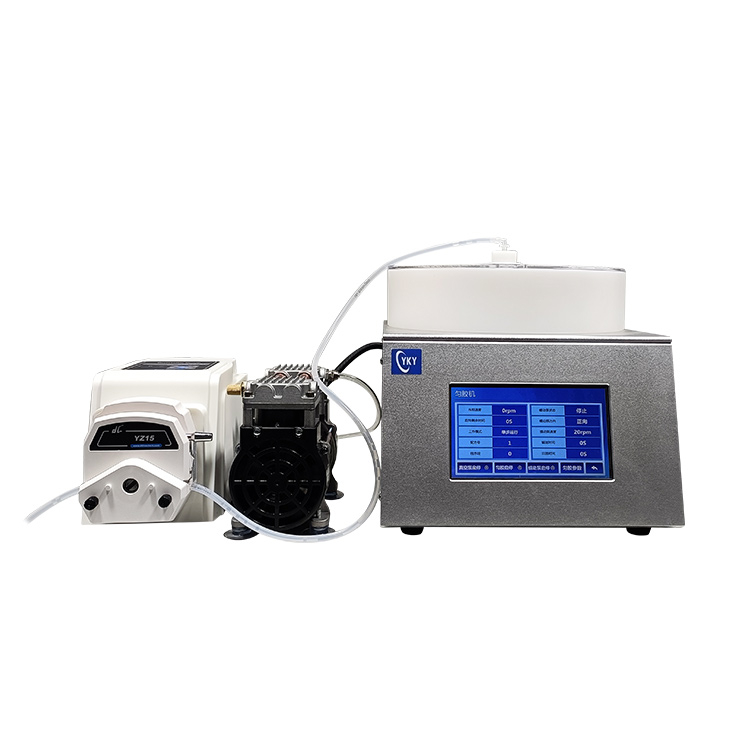

Syringe Pump | Flow Rate Range | 50mL/min |

Syringe Pump Specification | 10ml Accuracy +/- 0.01 mL |

Syringe Pump Specification | 100mL Accuracy +/- 0.01 mL |

Linear Speed Range | 5µm/min-65mm/min |

Linear Speed Adjustment Resolution | 5µm/min |

Max. Stroke | 140mm |

Stroke Resolution | 0.156µm |

Rated Linear Thrust | >90N |

Flow Meter | Controlled Gas Types | 2 types |

Gas Flow Rate | 16-160mL/min |