The physical process of thermal evaporation coating instrument mainly includes evaporation of materials, transportation of gaseous particles and deposition and film formation on the substrate. During the evaporation process, the material needs to obtain enough thermal energy to overcome the binding energy between molecules, so as to transform into gaseous molecules and escape from the surface of the evaporation source. These gaseous particles fly straight to the substrate surface basically without collision during the transportation process, where they condense and nucleate to grow into a solid phase film

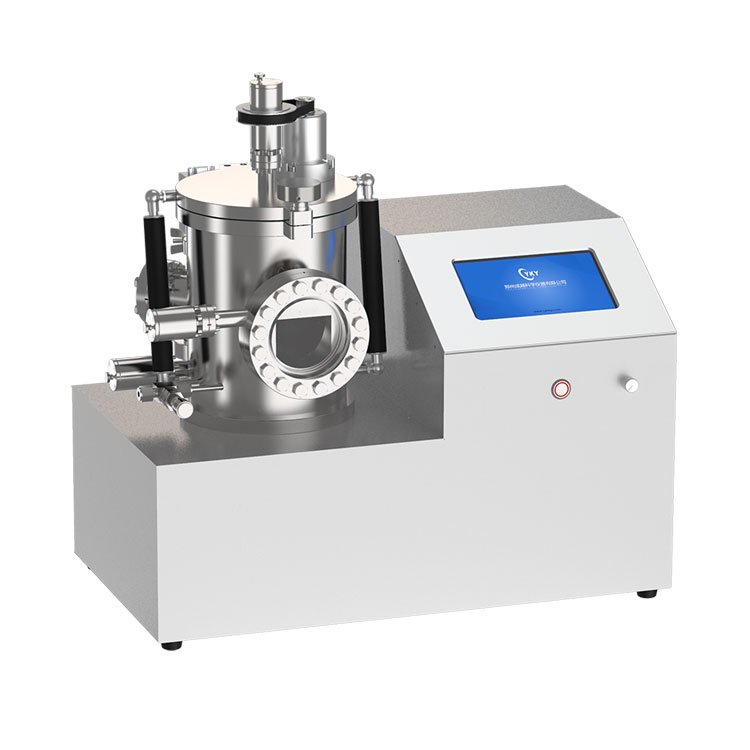

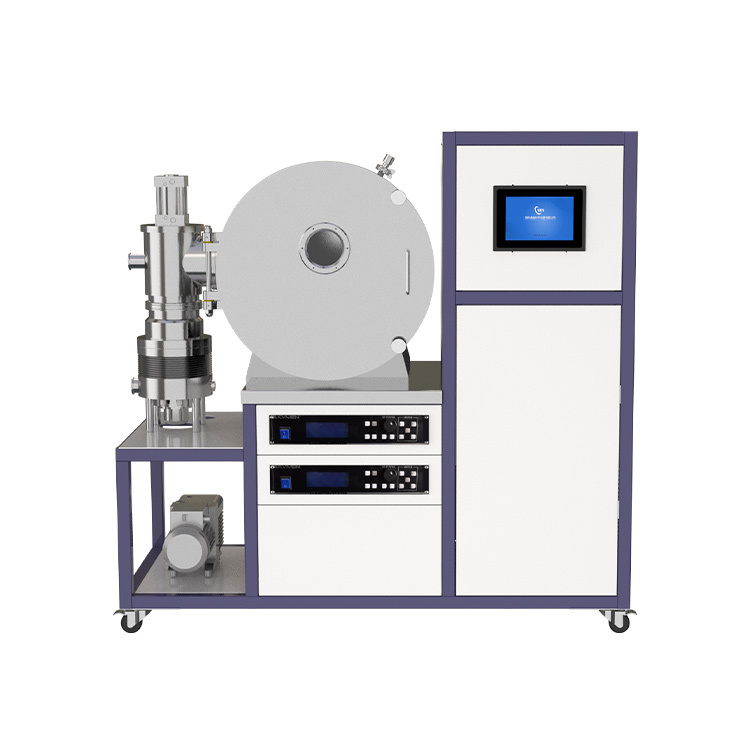

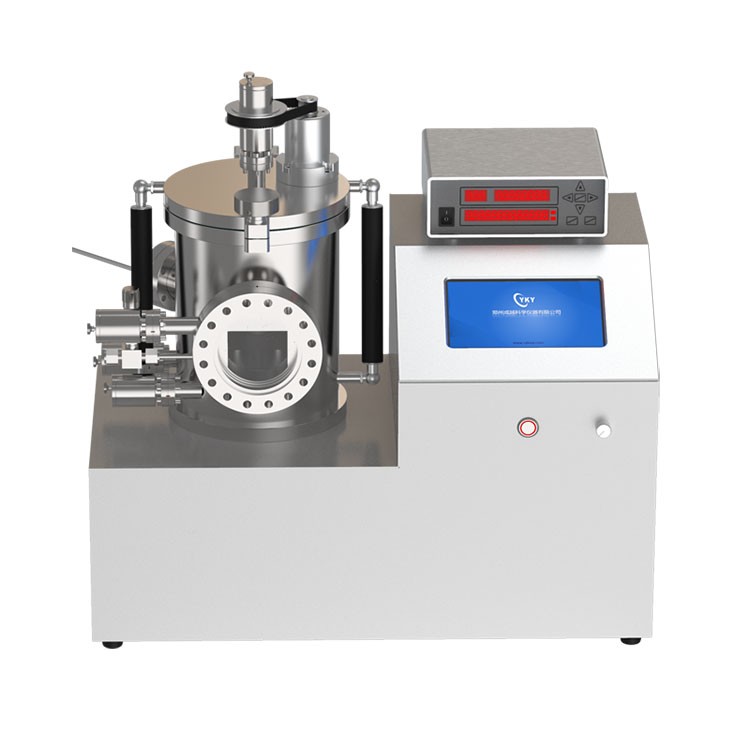

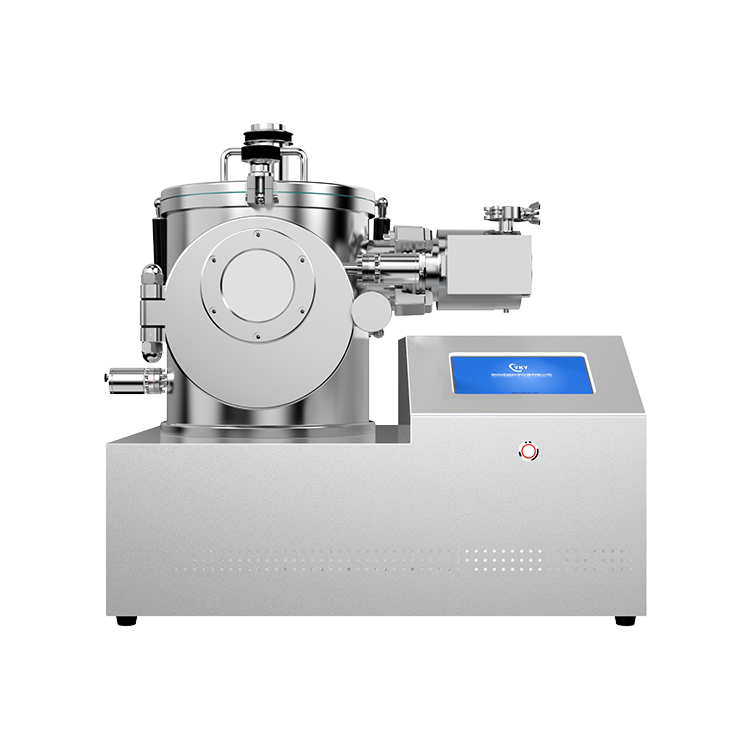

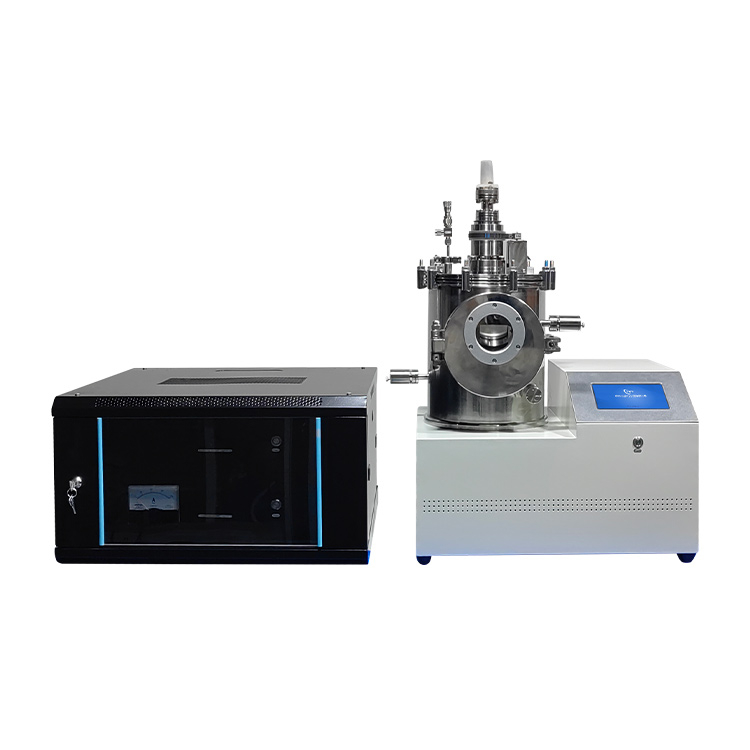

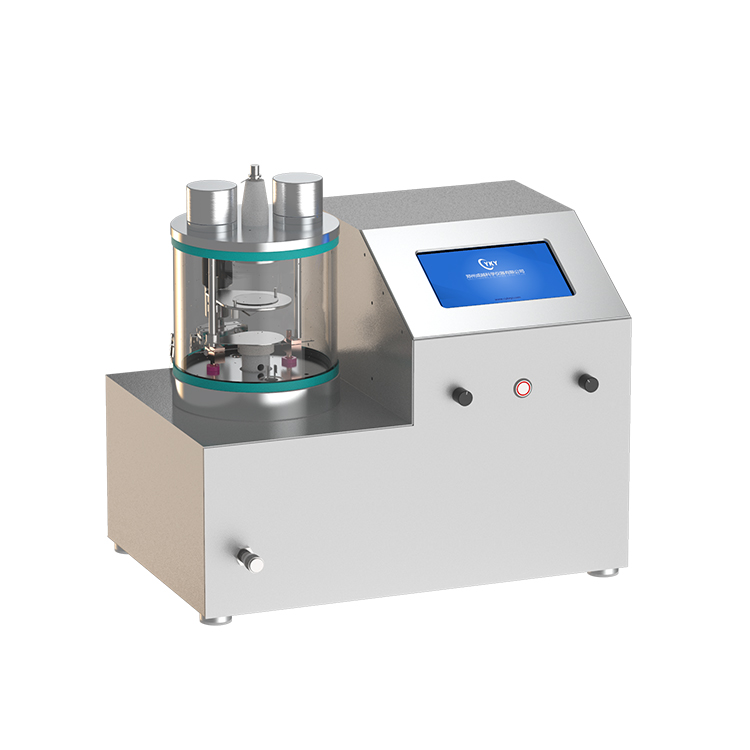

This product is a desktop small evaporation coating instrument designed for high vacuum. It can provide a maximum coating current of 150A and a maximum evaporation temperature of up to 1800℃, which can meet the evaporation of various common metals and some non-metallic evaporation. The vacuum chamber is made of stainless steel and is degassed at the factory. It can reach a limit vacuum of 5x10-5Pa with the molecular pump group, which can meet the vacuum environment required for the evaporation of most materials. The vacuum chamber adopts the front door opening method, which is convenient for taking and placing samples. The chamber is equipped with an adaptive observation window with a baffle for observing the coating process. The baffle can effectively prevent the observation window from being contaminated by the film material.

Product features of evaporation coating instrument:

High-purity film: Since it is carried out under high vacuum conditions, the collision between gas molecules and evaporation materials is reduced, so that high-purity films can be prepared.

Precise control: Evaporation coating technology allows precise control of the thickness, composition and structure of the film, which is crucial in many high-precision applications.

Applicable to a variety of materials: Evaporation coating technology can be used for a variety of materials, including metals, alloys, oxides, carbides, nitrides and organic materials.

High deposition rate: Especially when using electron beam evaporation, high deposition rate can be achieved because the high-energy electron beam can quickly heat the material.

Uniformity: By adjusting the appropriate process parameters, a uniform film can be obtained on a large area substrate.

Low damage: Since the heating is mainly concentrated on the evaporation material, the thermal impact on the substrate is small, which is suitable for thin film deposition of heat-sensitive materials.

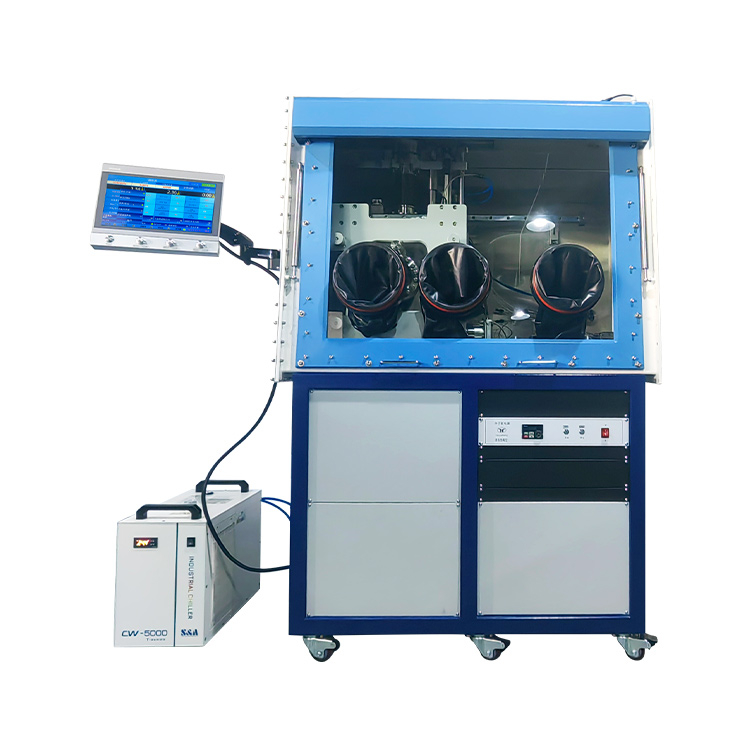

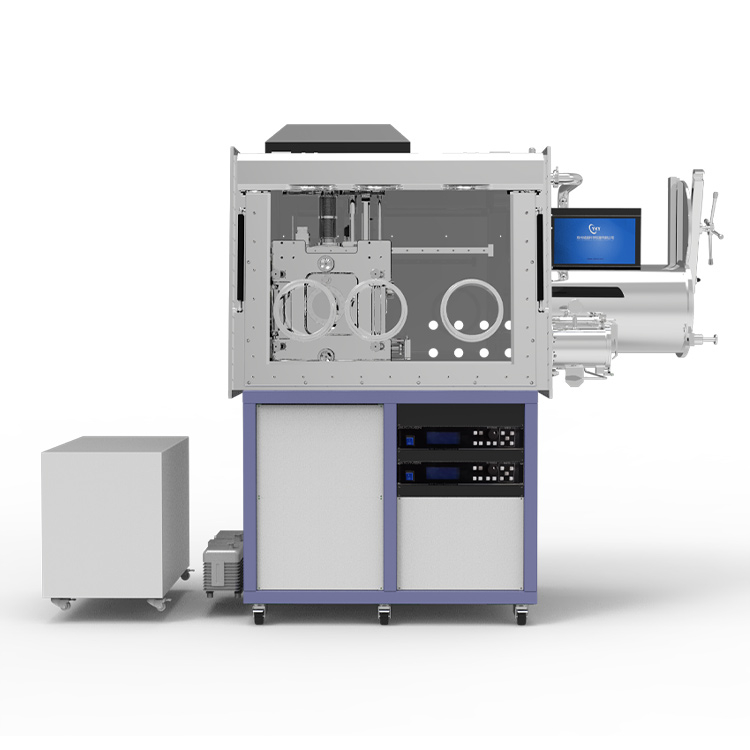

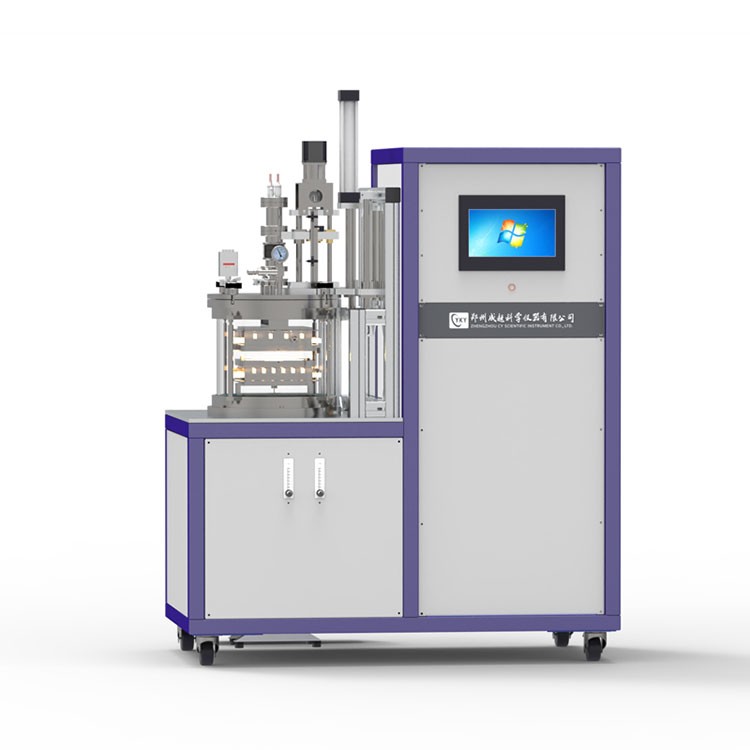

Technical parameters of three-source evaporation coating instrument:

Product name | Desktop three-source evaporation coating apparatus |

Product model | CY-EVZ254- III-H-SS |

Vacuum chamber | Cavity material | Made of 304 stainless steel welded, with polished surface |

Pick-and-place mode | Front-opening door for taking and placing samples and evaporation materials |

Observation window | 80mm diameter vacuum window, equipped with magnetic baffle to prevent contamination |

Sample stage | Sample size | ≦100mm |

Rotation speed | 0-20RPM |

Heating temperature | ≦300℃ |

Evaporation system | Evaporation source | 3 dock boats |

Coating method | Thermal evaporation coating |

Vacuum system | Vacuum port: KF25/40, exhaust port: KF16 |

Compound vacuum gauge |

Foreline pump | Rotary vane pump Pumping speed: 1.1L/S |

Molecular pump | Pumping speed: 60L/S (Osaka molecular pump) |

Film thickness measurement | Typically equipped with a CYKY film thickness measuring instrument |

Power supply voltage | AC220V,50Hz |

Machine power | 2KW |

Dimensions | 710mm X 480mm X690mm |

Packaging weight | 70 KG |