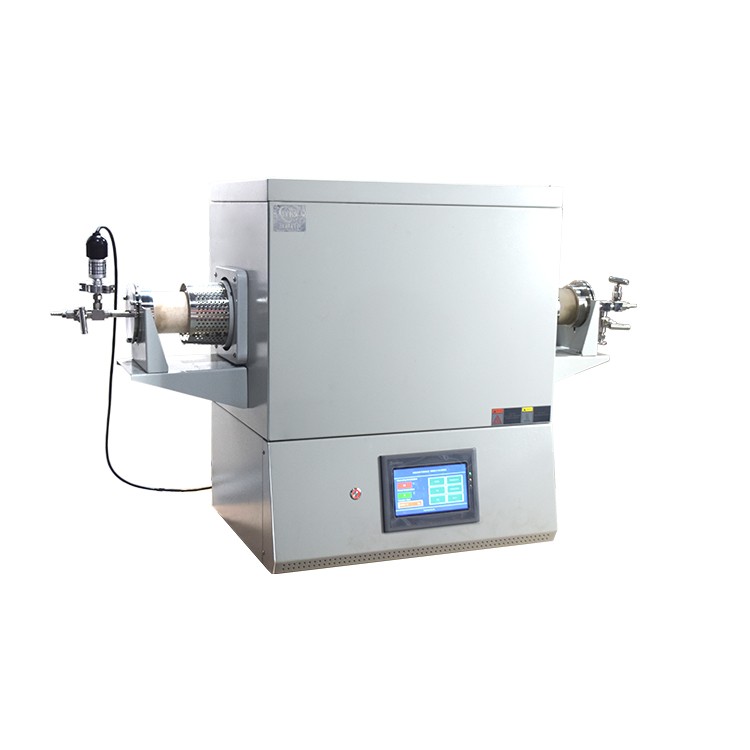

Working Temperature | 1150℃ |

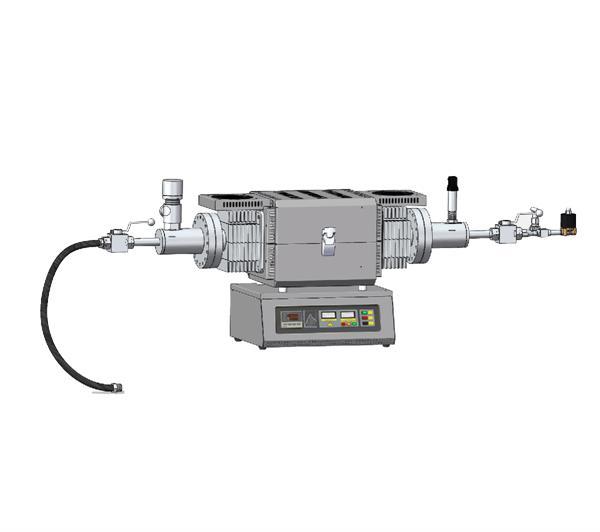

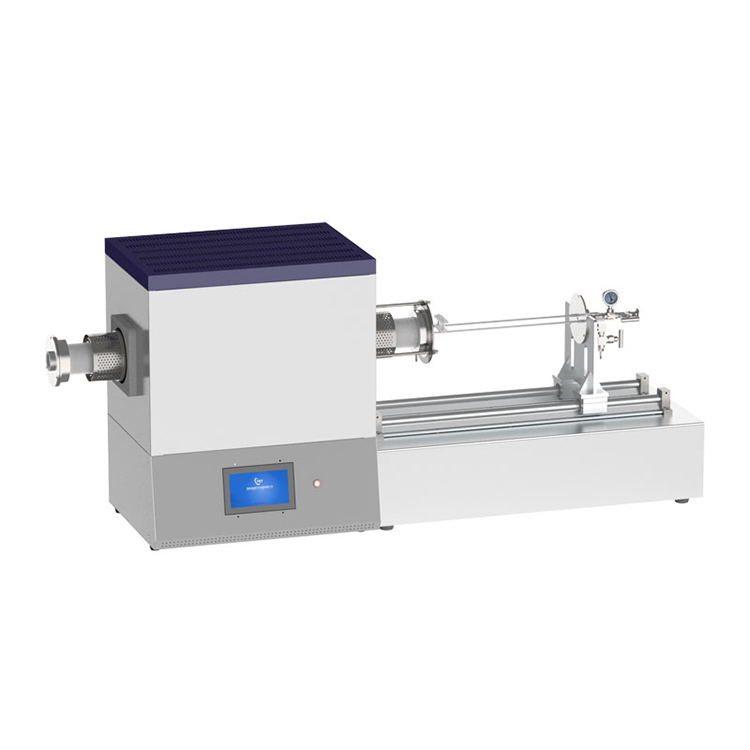

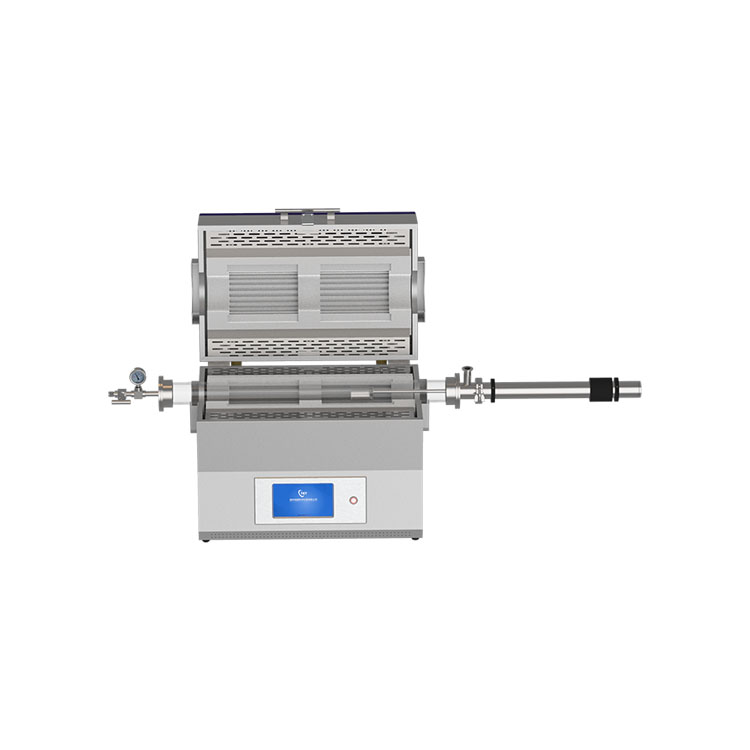

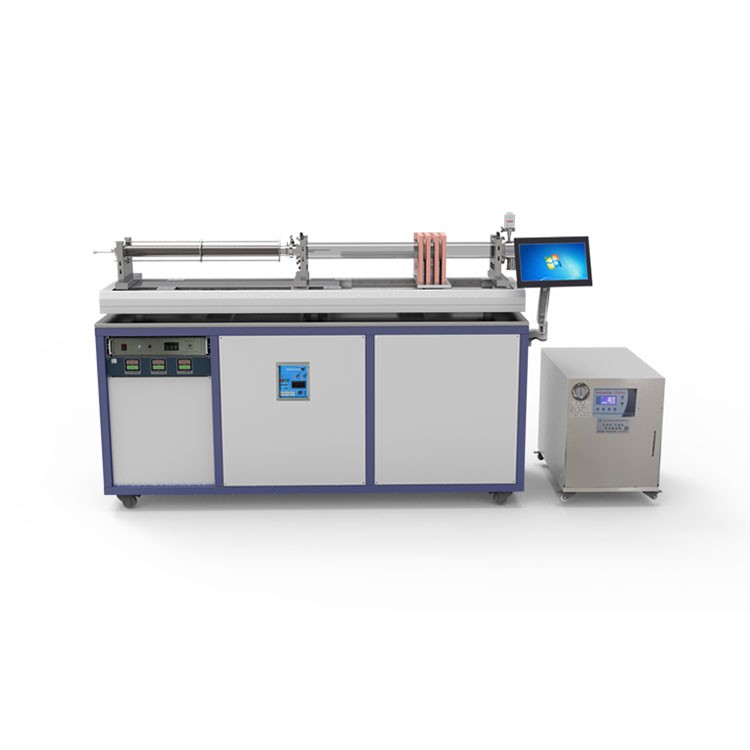

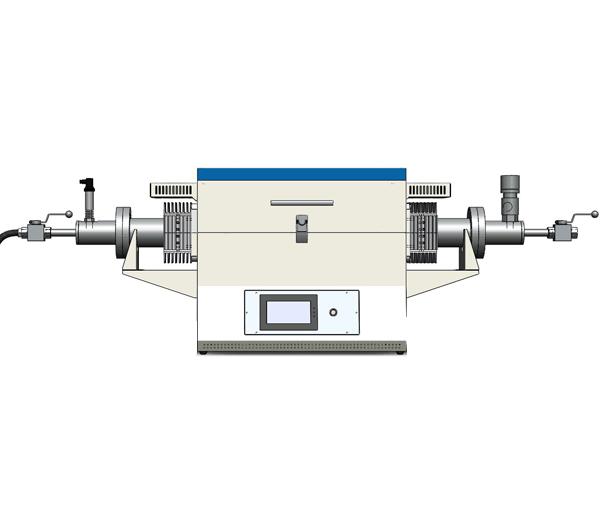

No. of Heating Zones | Three |

Length of Each Heating Zone | 300-400mm |

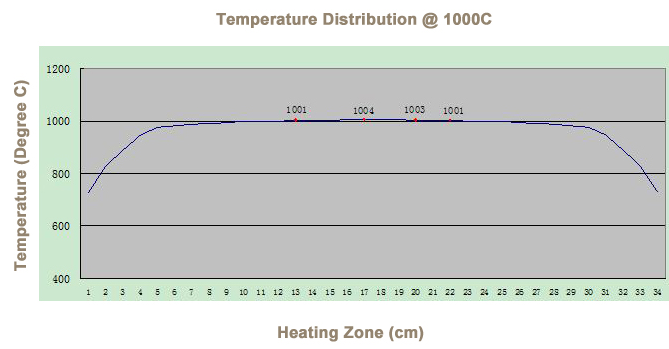

Length of Uniform Temperature Zone | 500 mm (Minimum) |

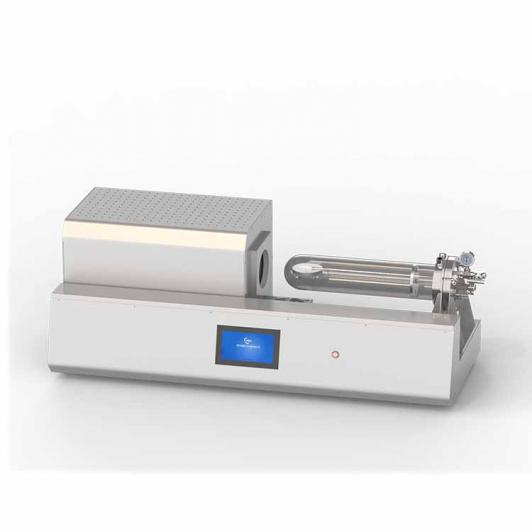

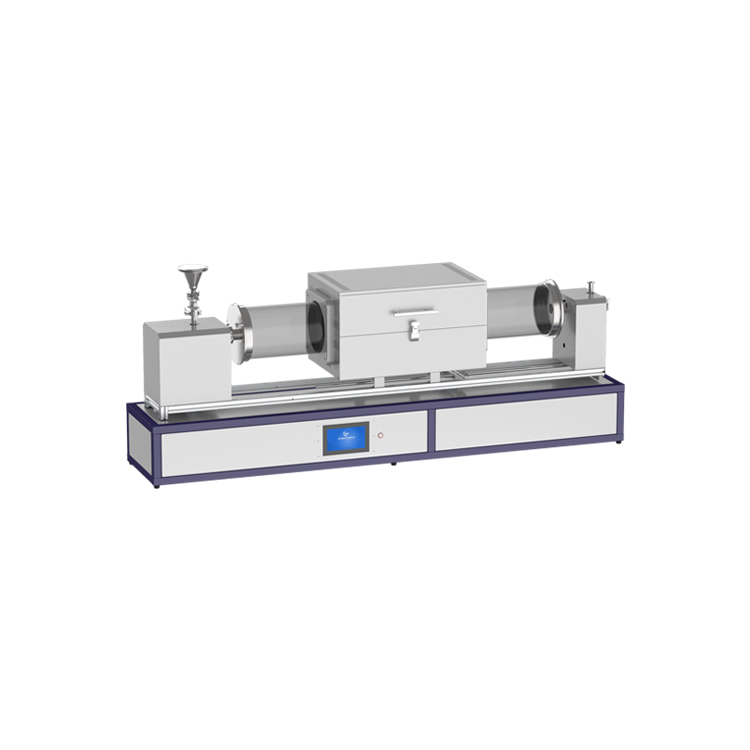

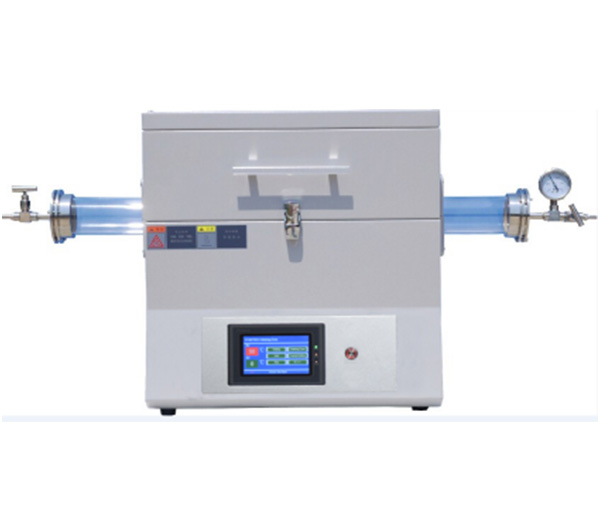

Material of vacuum tight working tube | Inconel 600 or equivalent Nickle base alloy suitable for above mentioned Temperature. Water cooling jackets on both ends of the working tube to be provided. |

Inside dia. of working tube | 100 mm (Minimum) |

Wall thickness of working tube | 5 mm (Minimum) |

Temperature uniformity | ± 5℃(In Uniform Temperature Zone) |

Temperature Control | By 03 Thyristors and 03 independent Programmable PID controllers (One for each heating zone), Minimum 8 Segments or other equivalent temperature controllers. Note: The temperature controllers must be selectable for all types of thermocouple. |

Safety Controller | A safety controller must be installed in the furnace to shut off the furnace in case of temperature shooting due failure of temperature control |

Thermocouples | 03 K type thermocouples for controlling/ measuring the temperature of 03 heating zones and 01 K type thermocouple for safety controller, all housed in SS-304 sleeves. Each thermocouple to be fixed in the center of each heating zone while thermocouple for safety controller to be fixed near the thermocouple of central heating zone. The thermocouples should be installed in the furnace in such a way that they should touch working tube but should not be damaged during splitting of the furnace. |

Furnace Body & Structure | Main structure: MS Channels Outer Body: Hot part made of MS, powder coated (in furnace) with hammer gray, while Cold Part (Control panel and other) made of MS powder coated (in furnace) with green or blue paint. Material of Insulation: Fiber Ceramic Board and Blanket (Bricks made of heavy Ceramic must not be used). |

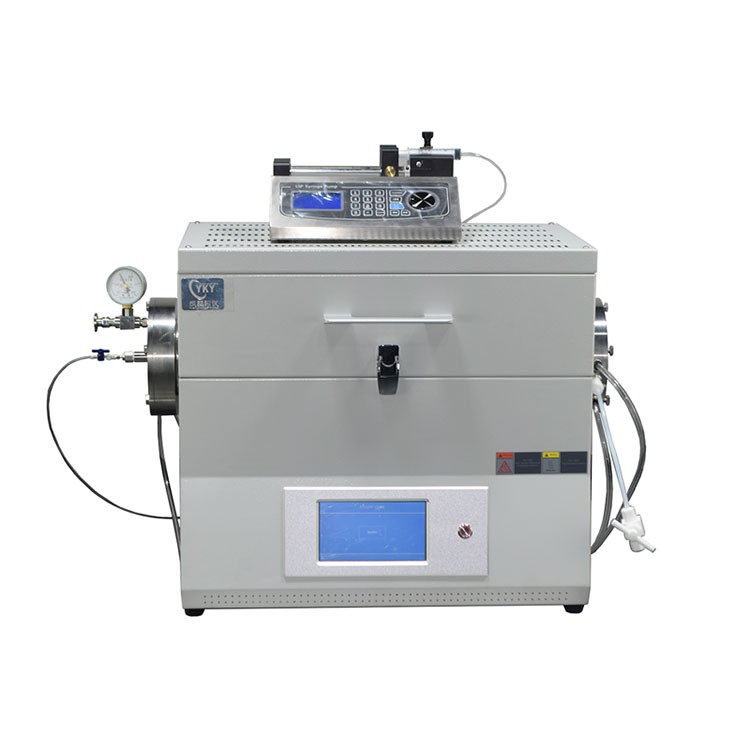

Vacuum System | High vacuum to be generated by rotary vane pump and oil diffusion pump incorporated in a vacuum station. The valves in the vacuum station are to be operated manually. Two stage rotary vane pump: pumping rate: 5L/s; Ultimate vacuum:1x 10-3 mbar. Oil Diffusion Pump: pumping rate: 600L/s; Ultimate vacuum: 1x 10-6 mbar. Vacuum Gauge & Controller: Vacuum gauge fitted in the working tube should be able to measure the vacuum during heating operation of the furnace. Measuring range: 1x 10-9 mbar. |

Electrical System | Heating: 380V, 3 phases, 50Hz, Approx. 45KVA Vacuum: 220V, single phase, 50Hz |