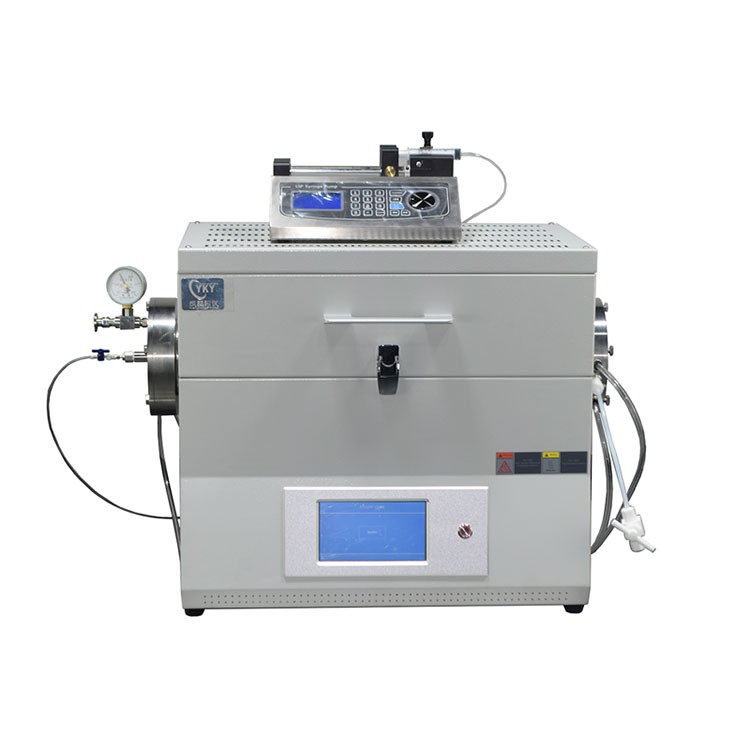

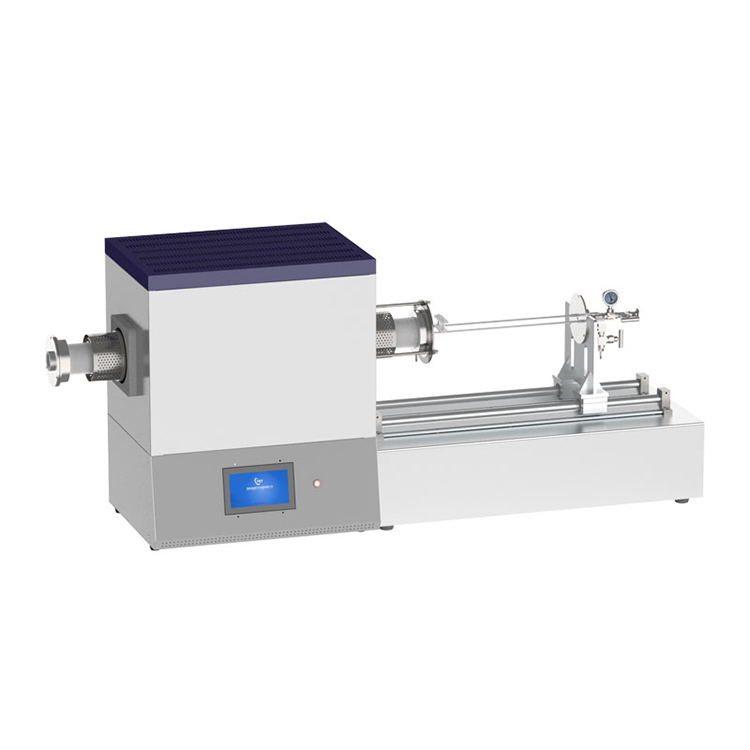

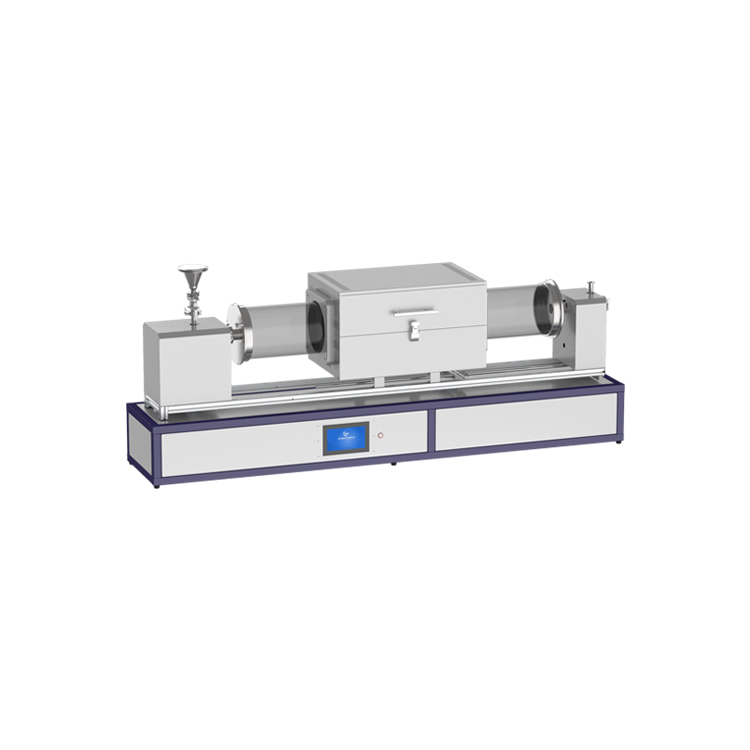

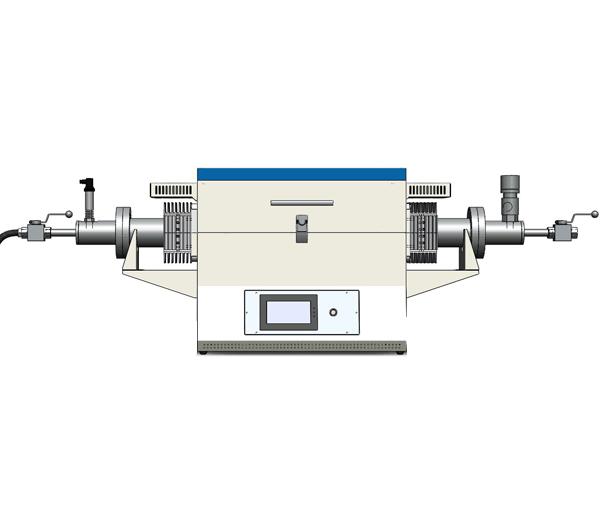

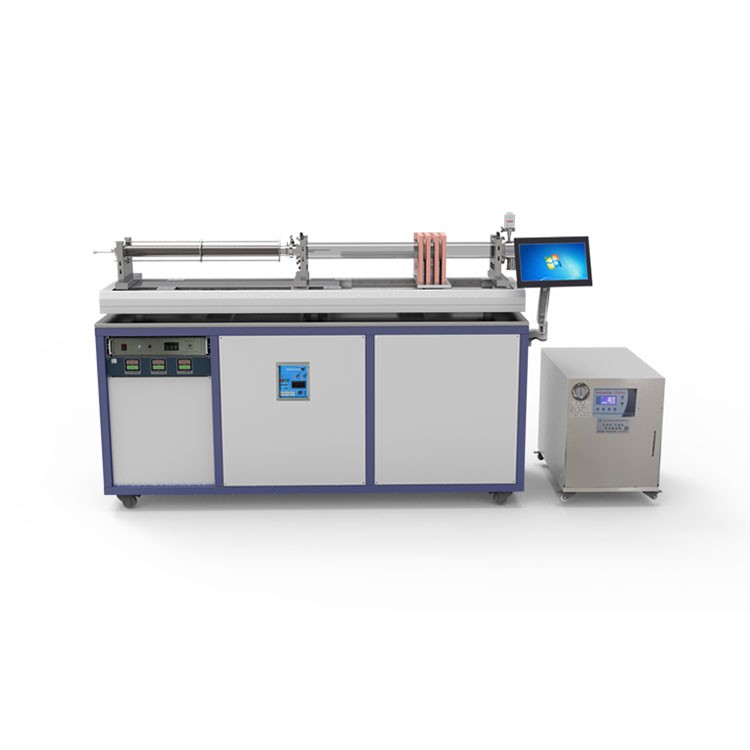

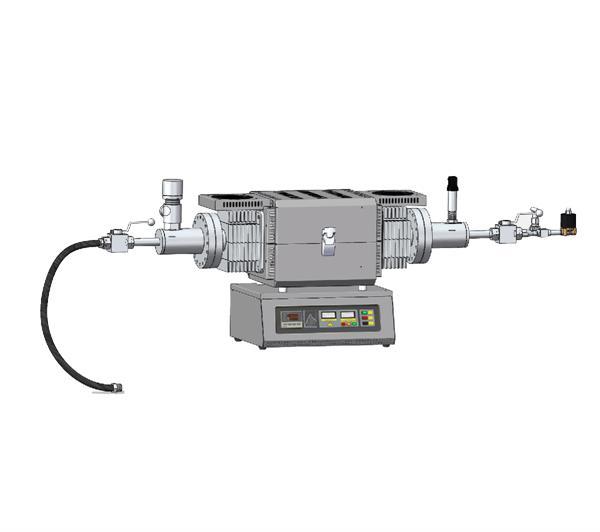

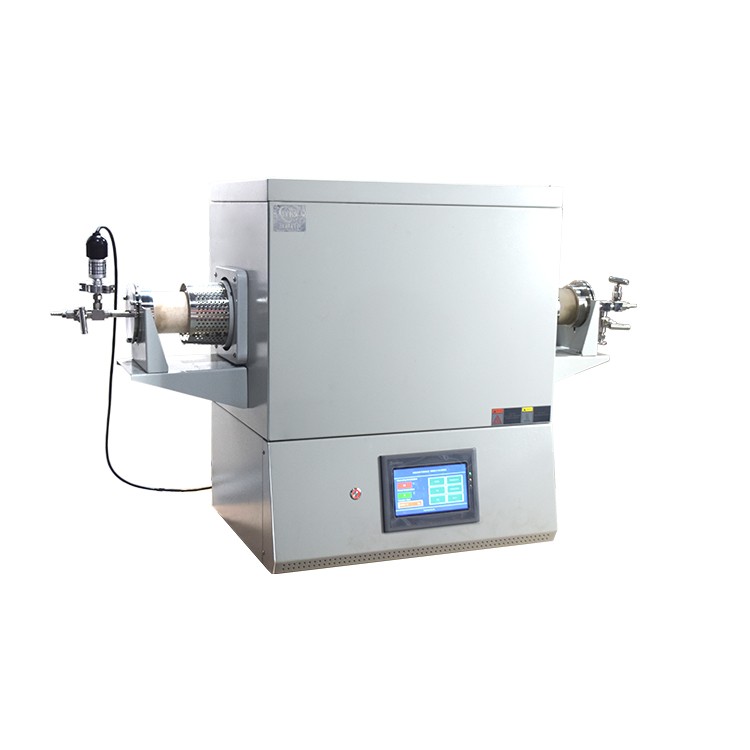

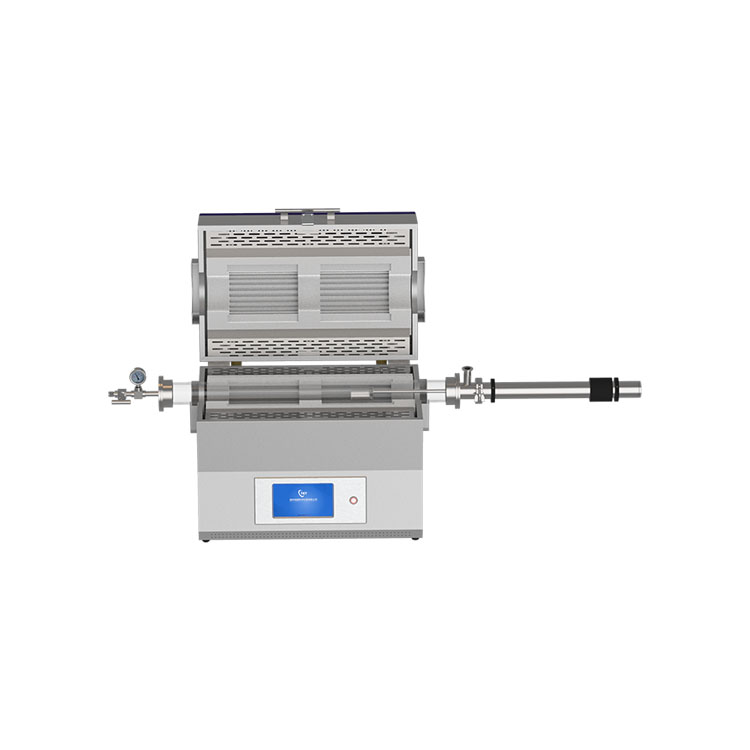

Furnace Structure |

Two Heating Zone Split Vertical Tube Furnace for longer and uniform constant temperature zone. The ultrasonic spray nozzle can make liquid/water atomized via gravity and low-pressure compressed air. Volumetric Feeder for feeding solid powder into a furnace to form core/ shell structure

|

Upgrade | If you need a horizontal furnace, we will change to the same specification tube furnace at no cost. You could upgrade from 40KHz to 3 KW and 120 KHz, Ultrasonic Spray Nozzle at extra cost

|

Power for Furnace | 6KW (total) / each zone: 3KW |

Voltage | AC 208-240V Single Phase, 50/60 Hz |

Max. Temperature | 1200℃ (<1 hr) each zone |

Continuous Temperature | 1100℃ for each zone |

Max. Heating Rate | <= 20℃/min. |

Temperature Accuracy | +/- 1℃ |

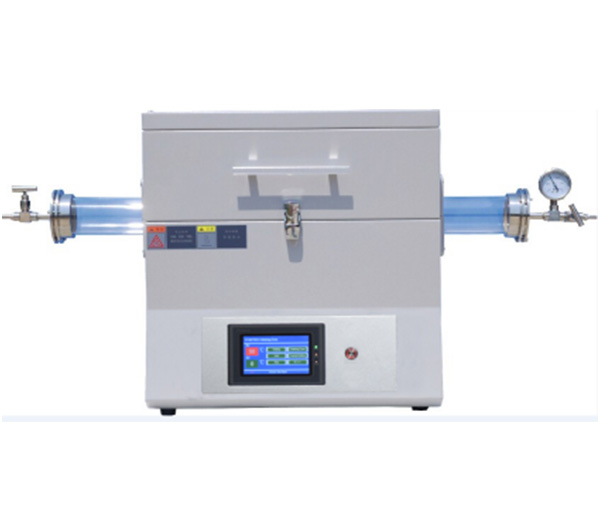

Tube Size and Materials | One 1000mm length quartz tube is included OD: 100 mm, ID. 95 mm Foam ceramic blocks with alumina coating are included, which is hanged on top of flange to protect O-ring damaged by heat radiation

|

Heating Zone Length | 200mm ( bottom ) 200mm ( top ) 400mm ( total )

|

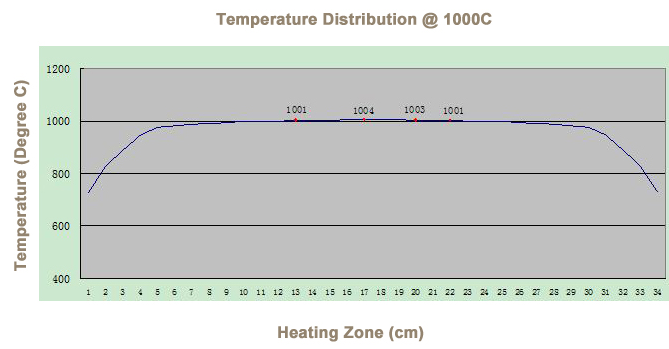

Constant Temperature Zone | Constant temperature zone: 300 mm (+/-1℃) if two heating zones are at the same temperature |

Temperature Controller | 30 programmable segments for precise control of heating rate, cooling rate and dwell time. Built in PID Auto-Tune function with overheating & broken thermocouple broken protection. Over temperature protection and alarm allows for operation without attendant(s). RS485 Communication Port.

|

Vacuum Sealing Flange | Gas outlet ( vacuum port ) on top with 1/4" barb connector. Gas inlet on bottom with 1/4" barb onnector

|

Vacuum Level | 10E-2 Torr by mechanical vacuum pump 10E-5 Torr by molecular pump Leak rate < 5 mTorr / min.

|

Heating Element | 1300°C Fe-Cr-Al Alloy doped by Mo |

Dimensions | 550mm(L) x 380mm(W) x 520mm(H) exclude mobile cart 600mm(L) x 600mm(W) x 1200mm(H) install with mobile cart |

Net Weight | About 80 kg (excluding mobile cart) |

Shipping Size | 48"(L) x 40"(W) x 72''(H) |

Shipping Weight | 400 lbs |

Warranty | One year limited warranty with lifetime support |