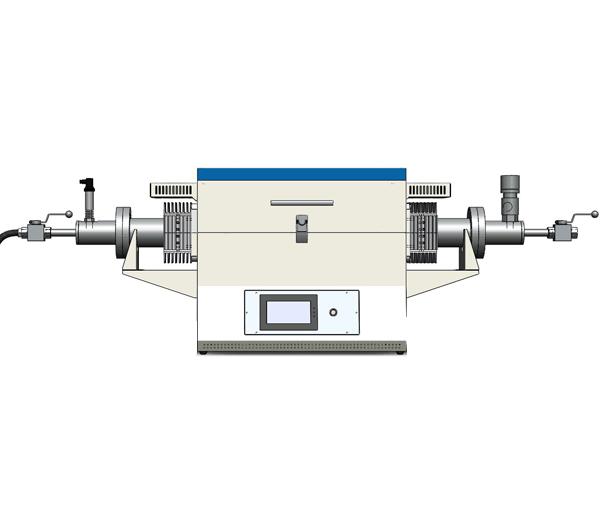

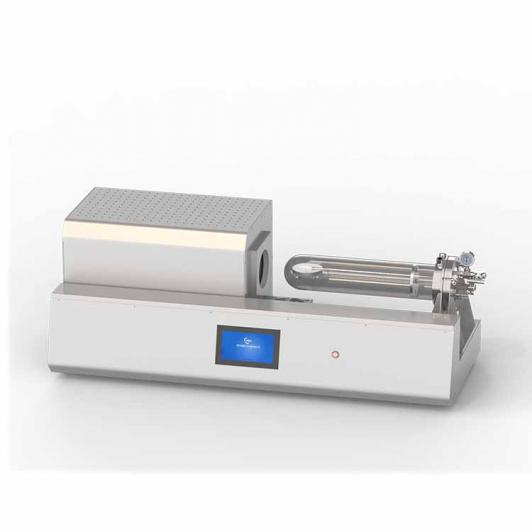

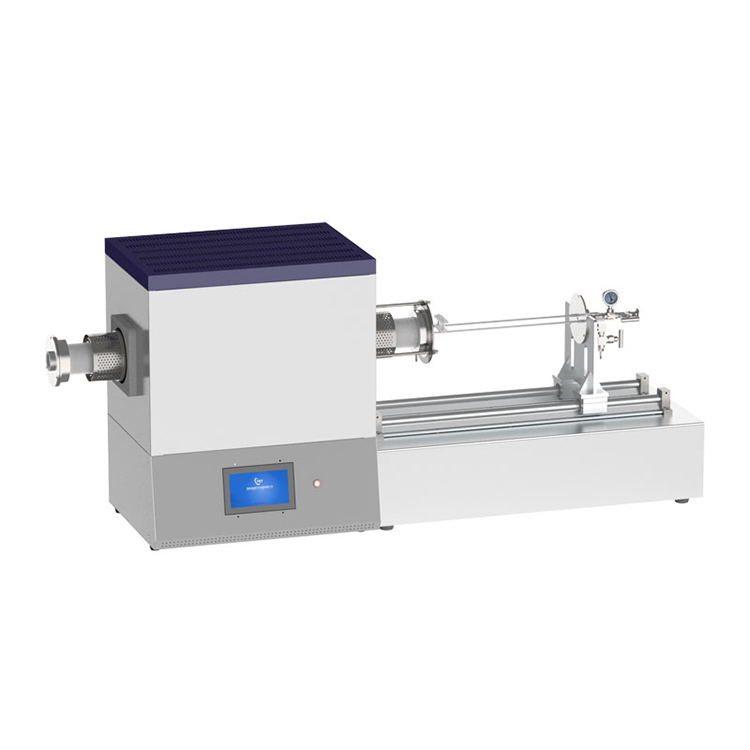

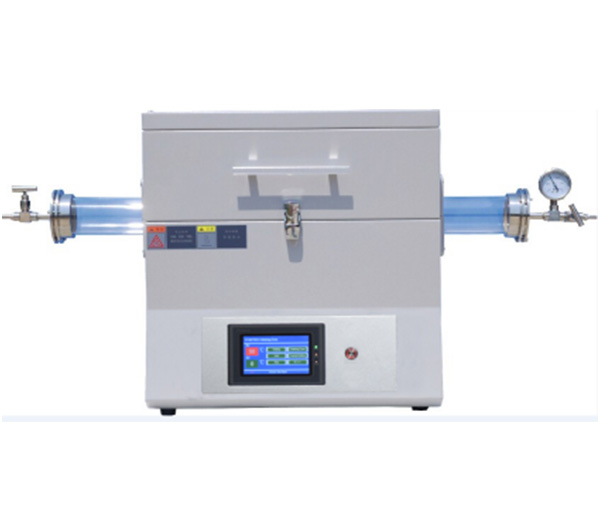

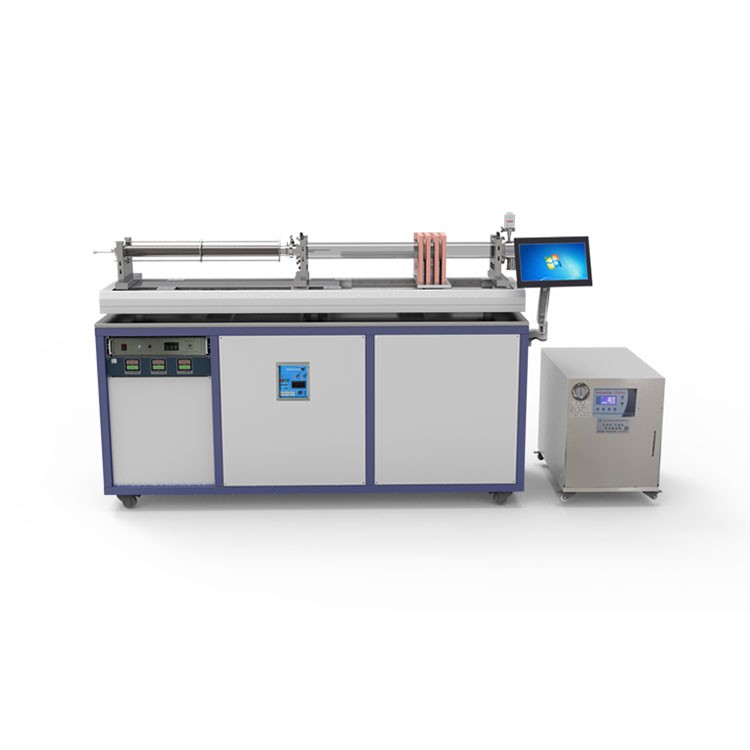

A steel strip annealing furnace is a continuous-type industrial heat treatment furnace specifically designed for annealing processes of metal strips or wires such as stainless steel, copper, aluminum, and alloy steels. Its core working principle involves continuously passing metal strip materials through a controlled furnace atmosphere (e.g., nitrogen-hydrogen mixture, pure hydrogen) under precise temperature profiles. This enables processes like recrystallization, softening, internal stress relief, improvement of metallographic structure, or attainment of specific mechanical properties (e.g., tempering). It is a critical piece of equipment in deep metal processing and high-end manufacturing.

1. Application Areas

The steel strip annealing furnace is widely used in industries requiring high-performance metal materials, including the stainless steel sector, non-ferrous metals industry, special alloys and steel industry, as well as new energy and high-end manufacturing.

2. Product Advantages

Compared to batch-type furnaces such as box furnaces or bell furnaces, the continuous steel strip annealing furnace offers significant advantages:

High-Efficiency Continuous Production: Operates 7x24 hours non-stop with automated loading and unloading, achieving extremely high production efficiency.

Exceptional Product Quality:

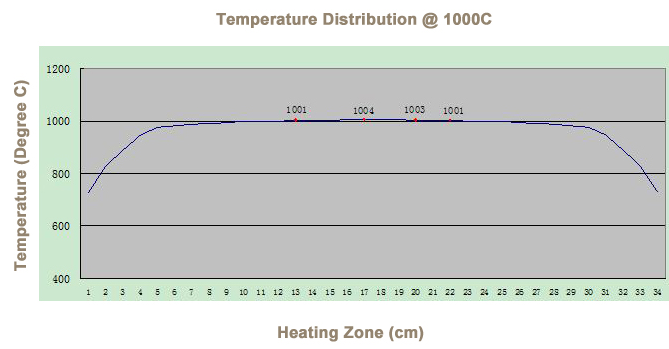

Uniform Performance: Highly uniform temperature field and atmosphere flow inside the furnace ensure consistent longitudinal and transverse properties of the strip.

Bright Surface: Utilizes high-purity protective atmospheres and rapid cooling technology to achieve an oxidation-free, decarburization-free bright surface, reducing subsequent pickling processes.

Excellent Energy Saving and Environmental Protection:

Low Energy Consumption: The continuous furnace design boasts high thermal efficiency, and waste heat recovery systems (e.g., heat exchangers) utilize exhaust heat to preheat combustion air or protective gas, resulting in significant energy savings.

Environmentally Clean: Uses clean energy sources (natural gas, electricity) combined with low-NOx combustion technology for clean emissions.

High Automation and Intelligence:

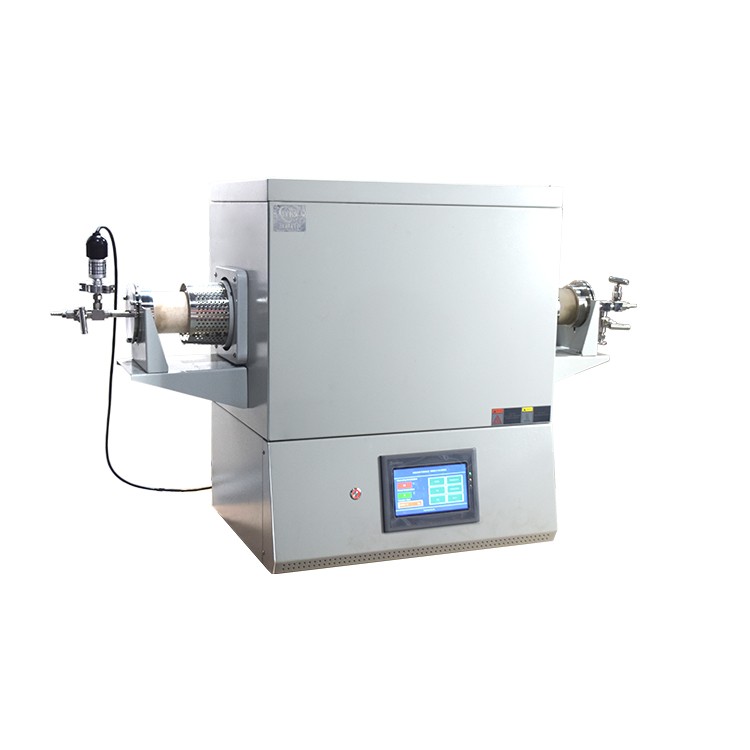

Full PLC/Computer Control: Enables closed-loop control of temperature, atmosphere, tension, and speed, along with storage of process recipes.

Data Traceability: Key parameters during production are recorded, facilitating quality traceability and analysis.

Flexible Process Adaptability: By adjusting furnace temperature zones, strip speed, and atmosphere composition, it can meet the heat treatment requirements of different materials, specifications, and processes.

3. Technical Parameters

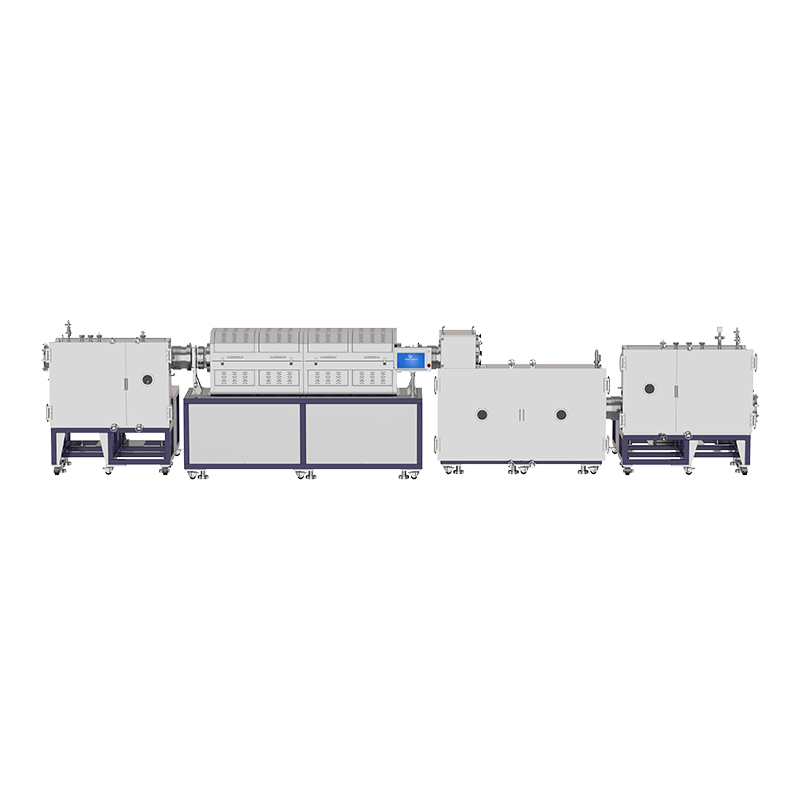

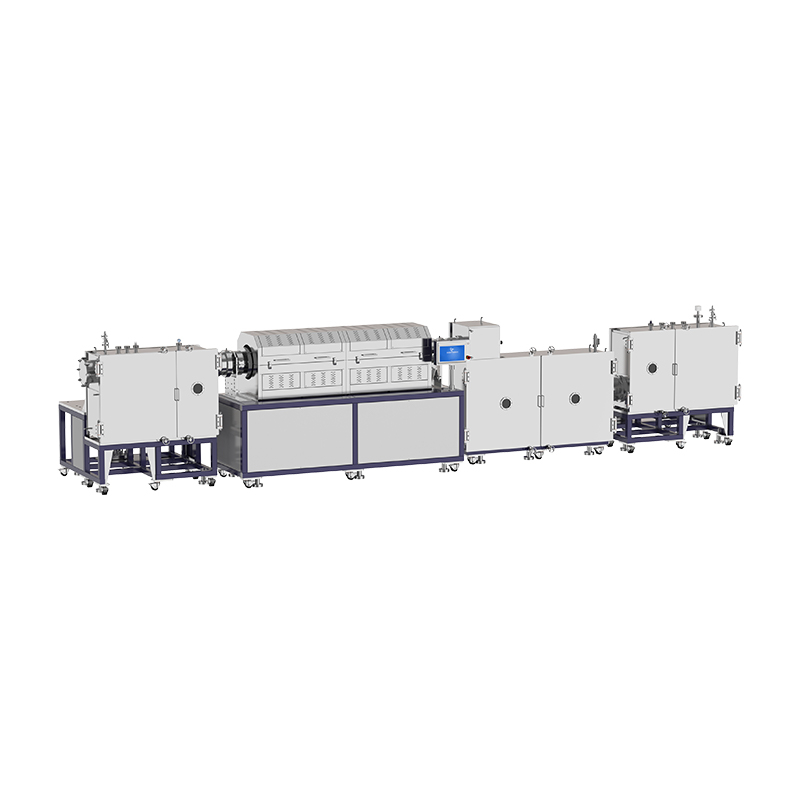

Product Name | Steel Strip Annealing Furnace |

Model | CY-O1200-Φ245-200-T |

Materials Processed | Stainless steel, copper, aluminum, alloy steels, etc. |

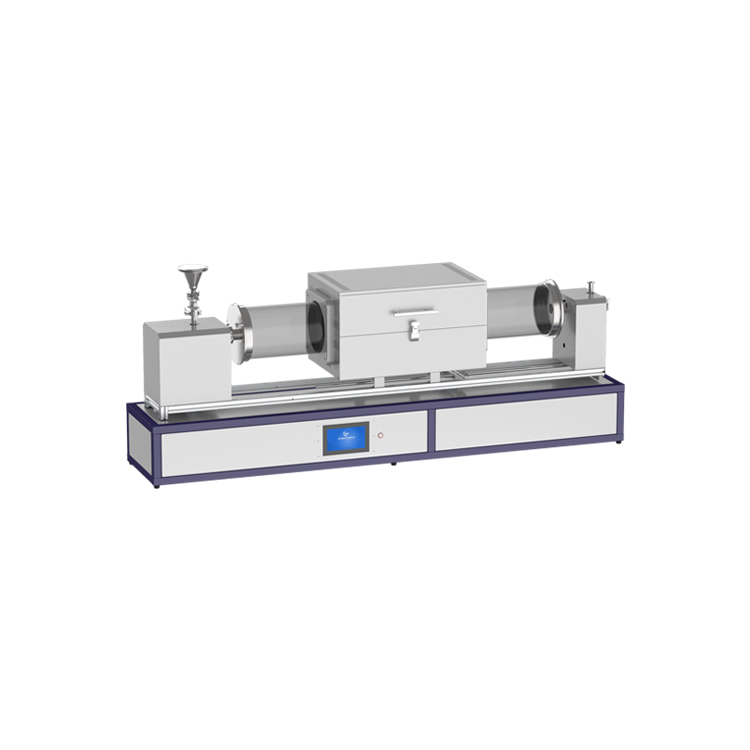

Annealed Strip Dimensions | Thickness: 20 - 250 µm, Width: 40 - 150 mm, Length: 2.5 km |

Strip Coil with Mounting Holes | 150mm |

Coil Outer Diameter | Approx. 600 mm |

Maximum Coil Weight | 200 kg |

Coil Winding Method | Galette |

Heating Section Max. Dimensions | L 10000 mm * W 3000 mm * H 2000 mm |

Maximum Operating Temperature | 800°C - 1250°C (Adjustable) |

Heating Method | Electric Heating / Gas Radiant Tube Heating |

Protective Atmosphere | N₂, H₂, H₂-N₂ Mixture |

Dew Point Control | ≤ -40°C (Can reach below -60°C) |

Operating Speed | 1 - 50 m/min (Adjustable) |

Tension Control | Constant Tension or Taper Tension Control |

Cooling Method | Air Jet Cooling, Water Jacket Cooling, Slow Cooling in Overaging Zone |