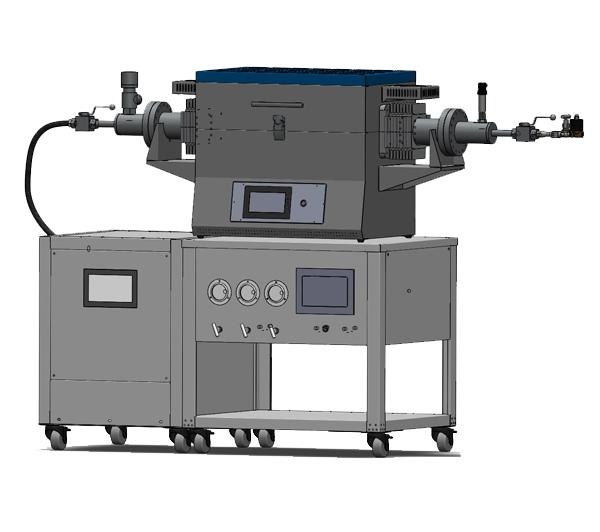

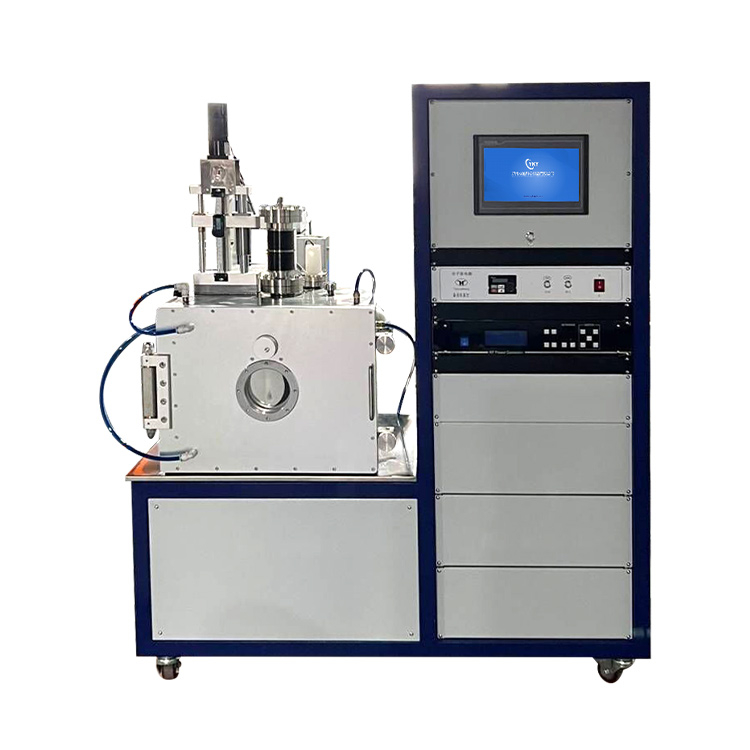

Product name | PECVD Chemical Vapor Deposition System |

Product model | CY-PECVD-500T-SS |

Power supply | AC220V 50Hz |

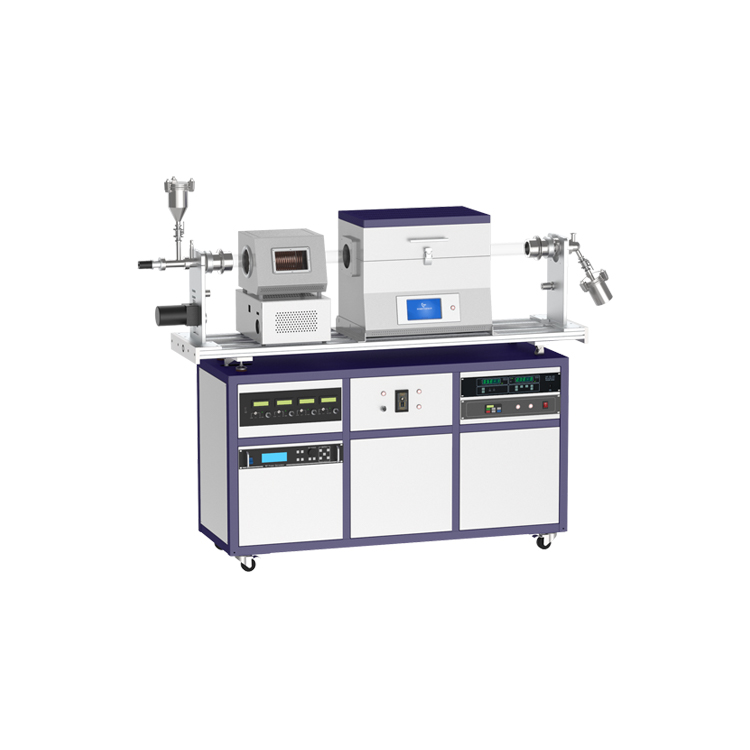

RF Power | Signal frequency | 13.56MHz |

Power output range | 0~300W |

Maximum reflected power | 100W |

Reflected power (at maximum power) | <5W |

Power stability | ±0.1% |

Working chamber | Heating temperature | RT-400℃ |

Temperature control accuracy | ±1℃ |

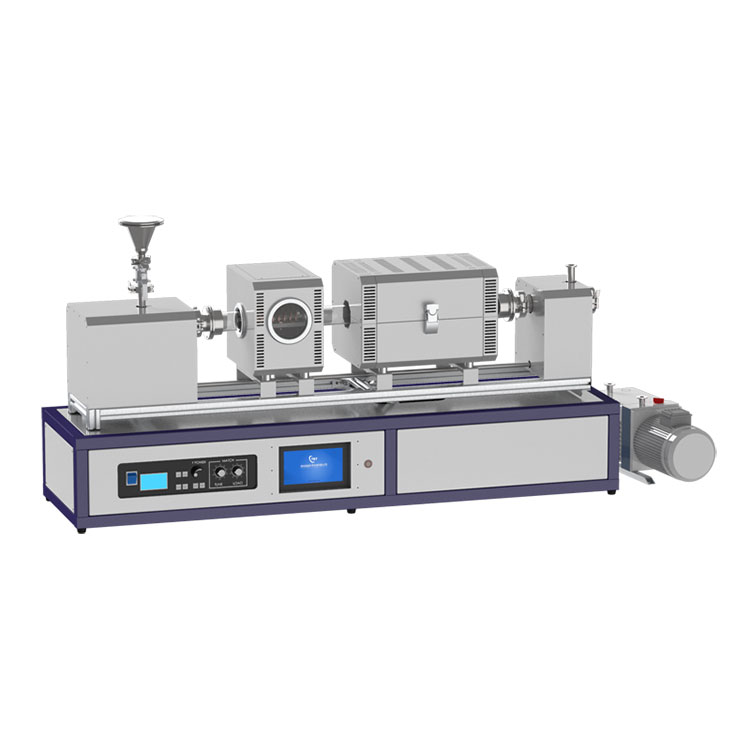

Sample stage size | Φ200mm |

Sample stage speed | 1-20rpm adjustable |

Nozzle size | Φ200mm |

Distance | The distance between the nozzle and the sample is 40-100mm continuously adjustable |

Deposition working vacuum | 0. 133- 133Pa (adjustable according to the process) |

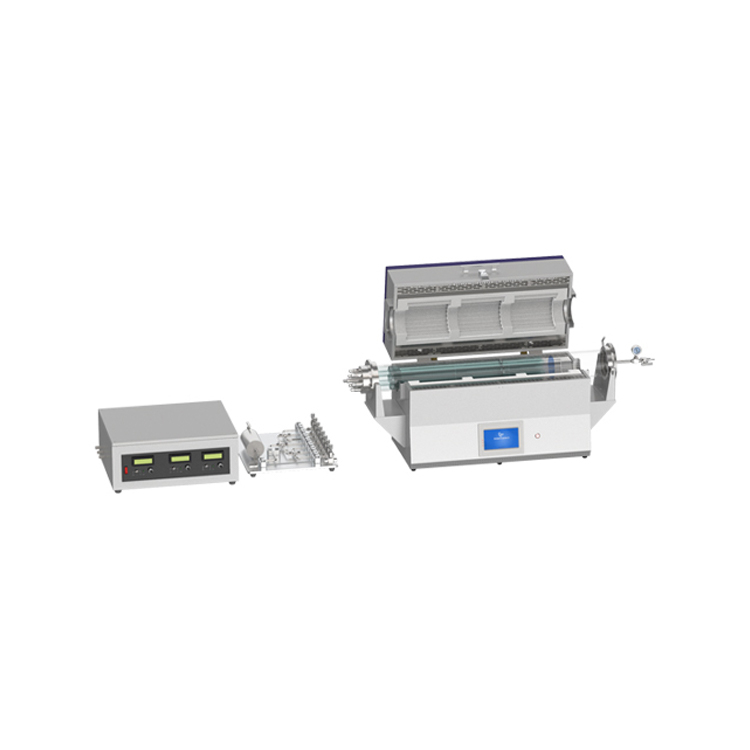

Flange | The upper cover design makes the substrate easy to replace and has a visual window |

Cavity | Stainless steel material, Φ500mm * 500mm |

Observation window | Φ40mm |

Gas supply system | Number of channels | Customized |

Measurement unit | Mass flow meter |

Measuring range | A channel: 0~200SCCM for H2 |

B channel: 0~200SCCM for CH4 |

C channel: 0~200SCCM for C2H4 |

D channel: 0~500SCCM for N2 |

E channel: 0~500SCCM for NH3 |

F channel: 0~500SCCM for Ar |

Measurement accuracy | ±1.5%F.S |

Working pressure difference | -0.15Mpa~0.15Mpa |

Connecting pipe material | 304 stainless steel |

Gas path | 304 stainless steel needle valve |

Inlet and outlet interface specifications | 1/4" ferrule fitting |

Vacuum system | Pre-stage pump pumping speed | 4.7L/s |

Molecular pump pumping speed | 60L/s |

Vacuum measurement | Compound vacuum gauge, range 10-5Pa ~ 105Pa |

Vacuum degree | 5.0*10-3Pa |

Water Cooler | Cooling water temperature | ≦37℃ |

Water flow rate | 10L/min |

Power | 0.1KW |

Cooling power | 50W/℃ |

Air compressor | OTS-550 |

|

Product size | 1362*736*1434 |

Product weight | 280Kg |