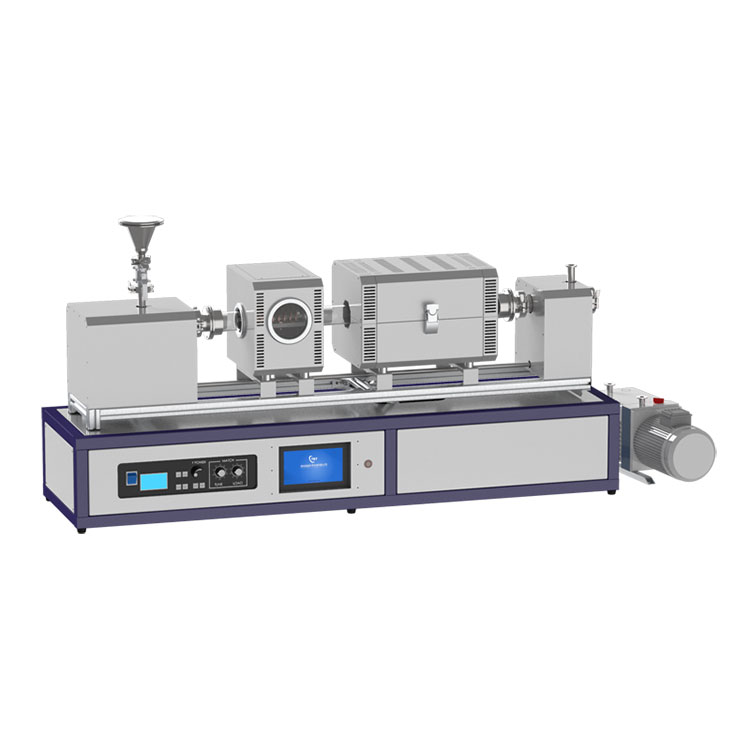

Device name | Perelin true air phase deposition equipment |

Product Model | CY-VPC-300 |

Work environment | Power supply: 380V five-wire 4 square cable, maximum power l0KW |

Ambient temperature: 0-40℃ |

Ambient humidity: < 90% |

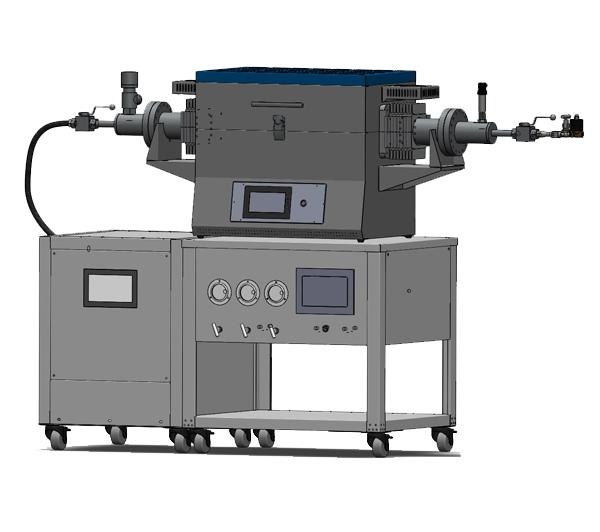

Size | The appearance size is1580*880*1550mm,covers an area of about 1.5 square meters, and there should be more than 50cm operating space around the installation |

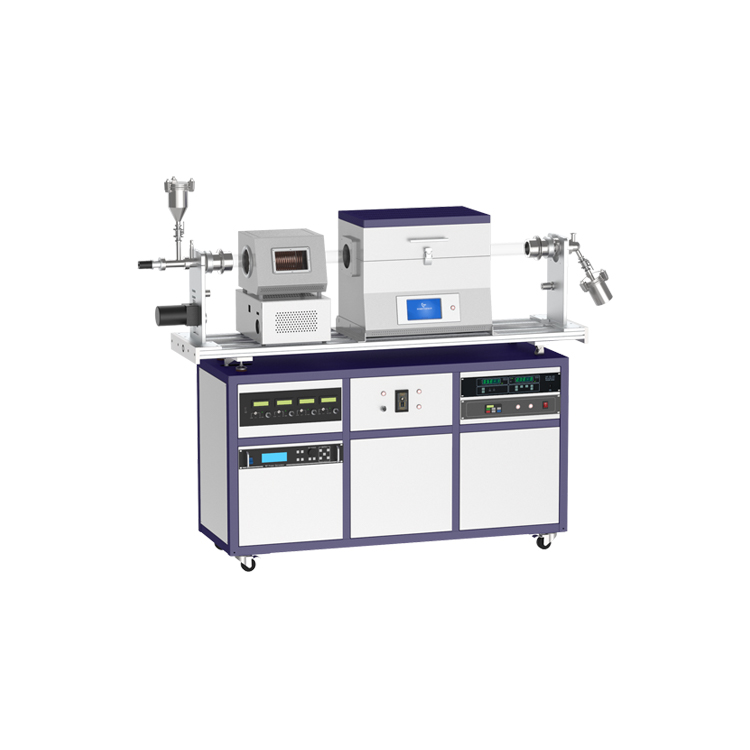

Heating part | Sublimation area | Raw material bin: φ69*200mm Capacity :300g |

Evaporation temperature: room temperature 200℃ |

Temperature deviation :±2℃ |

Cracking Zone | Cracking temperature :650-7℃Temperature stability: ± 2℃ |

Insulation area | Heating temperature < 300℃ |

Control system | Branding | PLC control system |

Program | There are two parts for automatic deposition system and manual deposition system |

Display | Display size :12 "touch color screen |

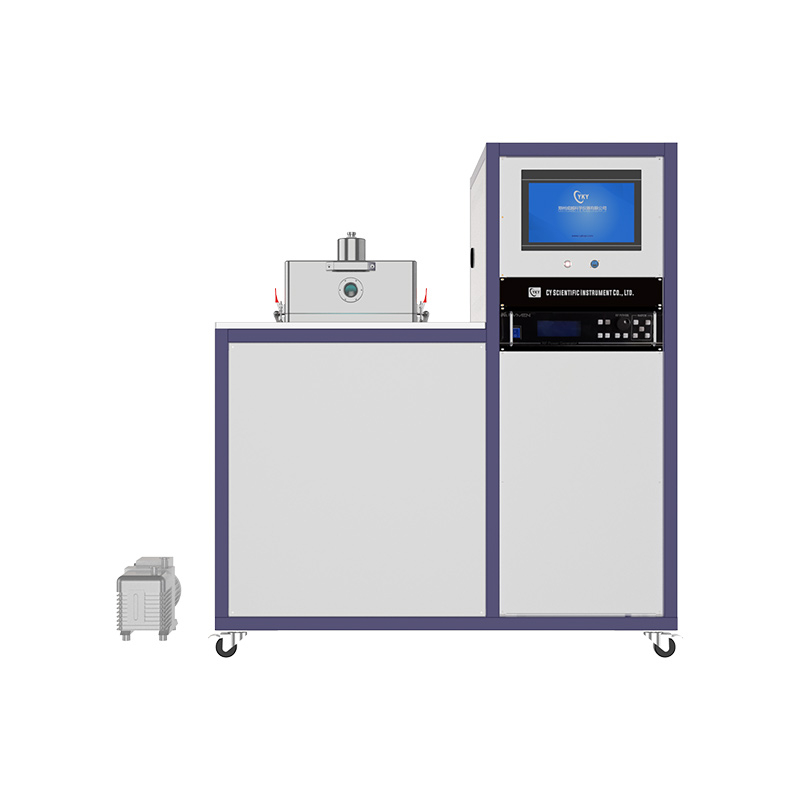

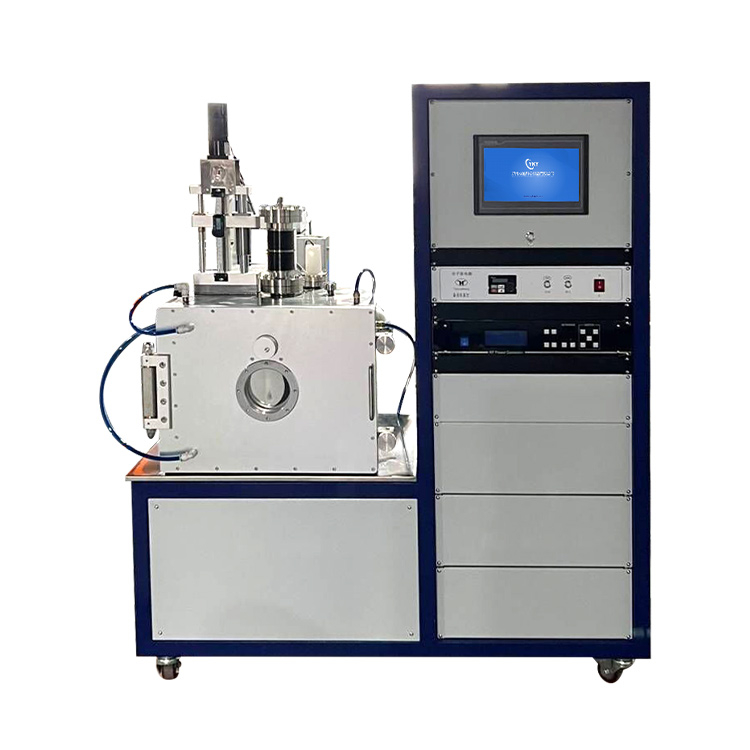

Depositional system | Vacuum substrate | 1, size φ300xH400, 304 stainless steel |

Chamber | 28L |

Observation window | 1,viewing window for easy observation of the condition of the product in the deposition chamber |

Rotating section | Motor speed adjustable 1-10 RPM |

Refrigeration system | ColdTH-95-15-G(pottype),refrigeration temperature ≤90℃within30 minutes after starting refrigeration can be from room temperature to -70℃ |

Coupling agent evaporation device | Improve the adhesion of the perelin coating to the surface of the substrate to be coated |

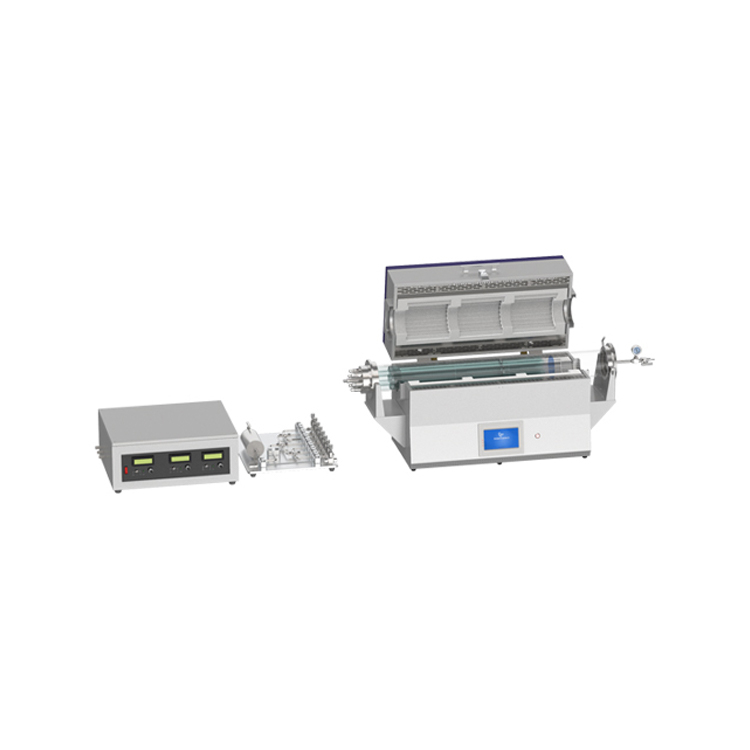

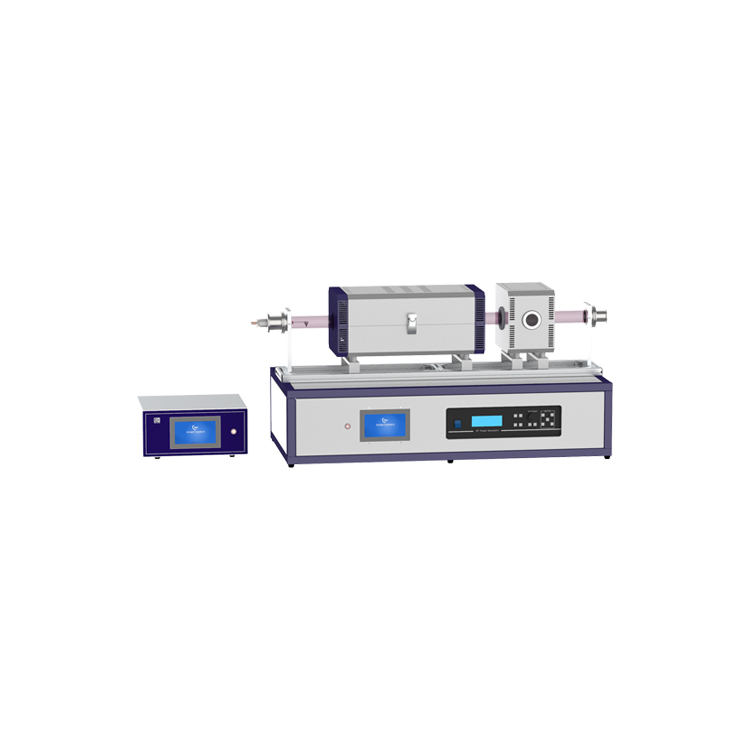

Main parts of equipment | 1, evaporation system: evaporation chamber,electric power n heat device, temperature sensor 2, cracking system: cracking chamber, electric thermal device, temperature sensor 3, deposition system: deposition chamber, vacuum sensor, sample rack 4, vacuum system: vacuum pump, vacuum gauge 5, condensing system: pot type cold trap 6, equipment host: equipment shell, control circuit, vacuum pipe 7, quartz tube: 1 |

Sedimentable raw material type | Parylene C, N, F, D |

Equipment Features | 1, the gasification heating can be moved, suitable for continuous production, such as sudden power failure and other unexpected circumstances can be removed at anytime to ensure product safety. 2, the gasification part is a transparent glass tube, which can be viewed at any time, and can maintain low temperature production to meet the high requirements of coating. 3, gasification can be moved, is to send the patent setting, can ensure no patent conflict, production safety. 4. The special design of the internal rotating frame of the cavity can effectively reduce the number of bad points. 5. Visual and humanized interface, easy to understand operation.

6, glass tube,can greatly reduce the heating and cooling time. 7. The insulation part is optimized, so that Perelin is not easy to deposit in the inner wall of the glass tube, which can be maintained for a long time and reduce the maintenance time |