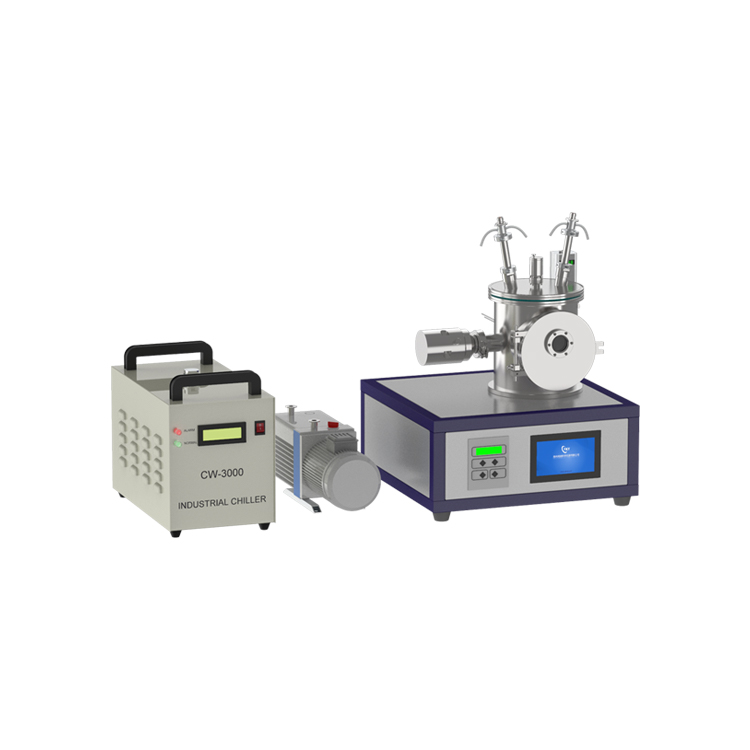

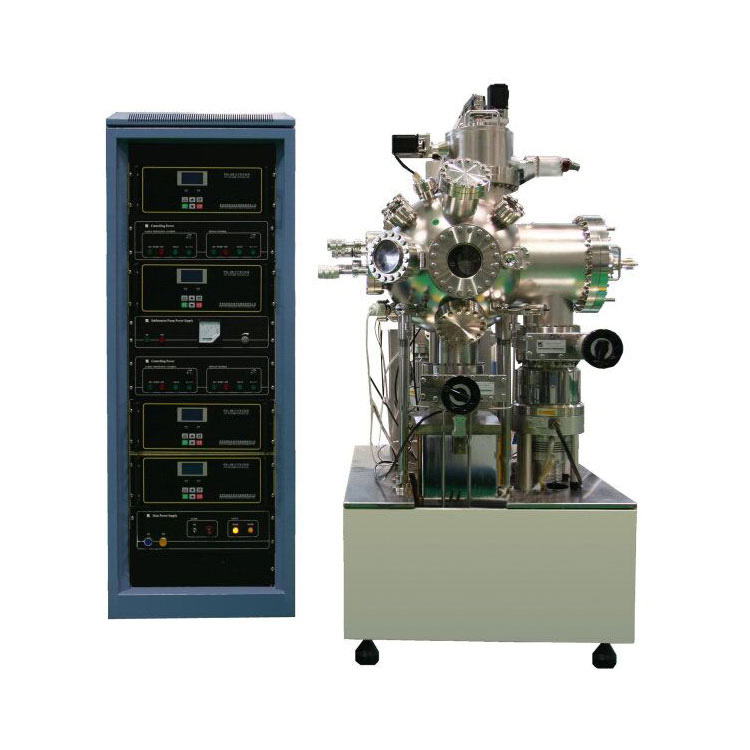

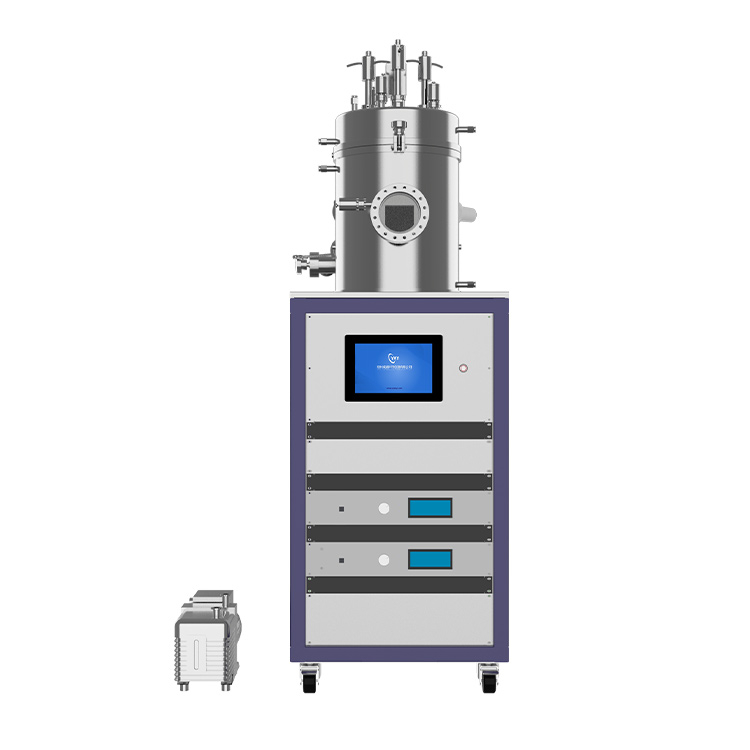

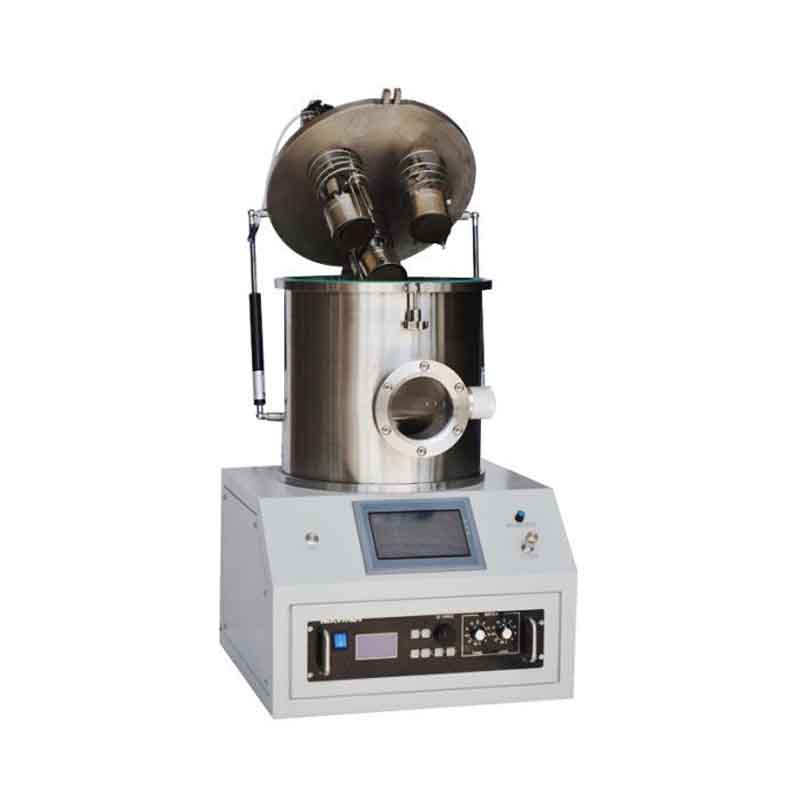

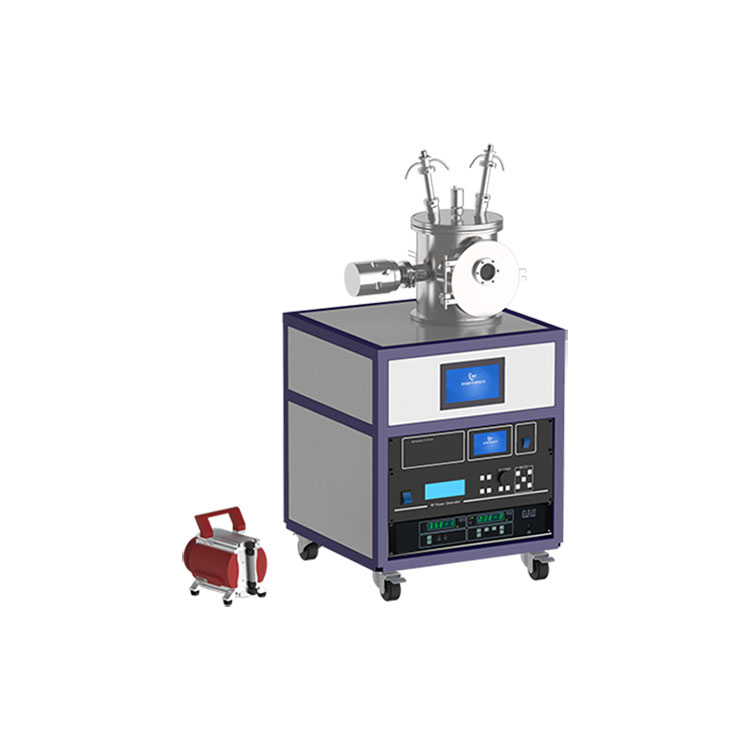

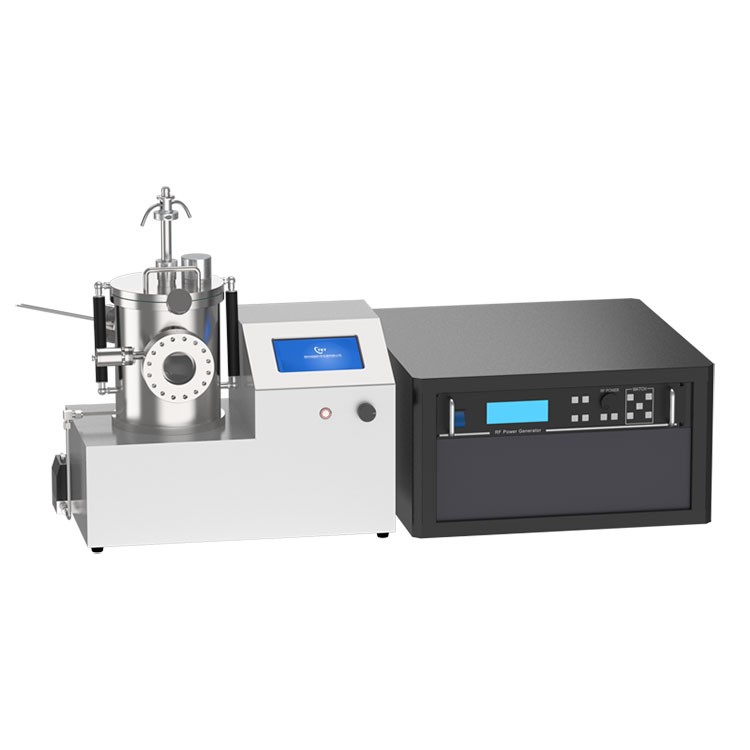

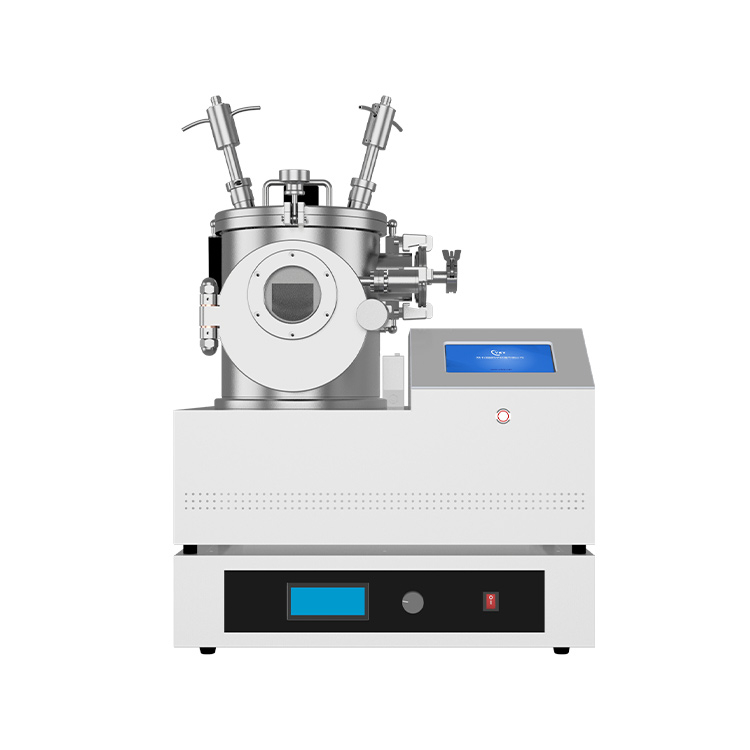

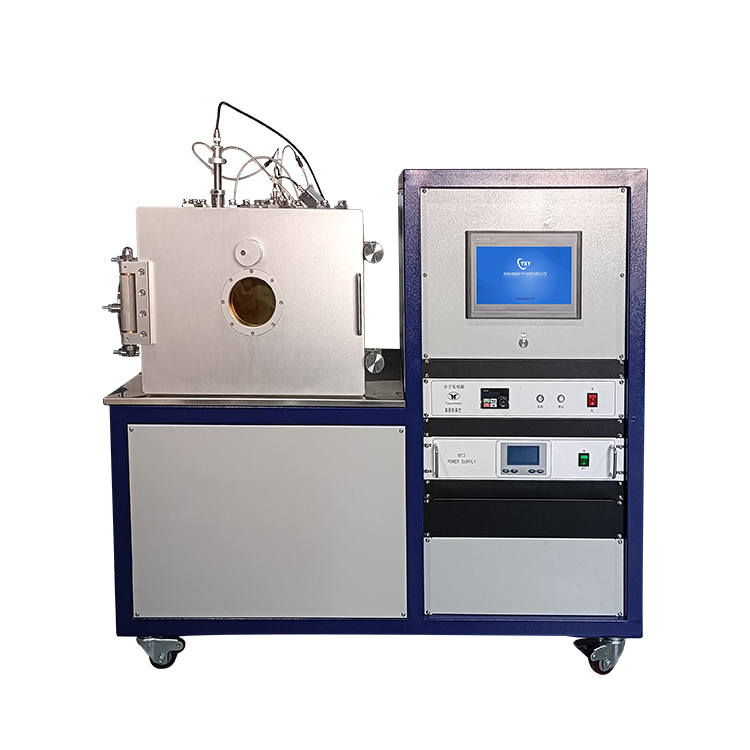

Features | 5 magnetron sputtering guns for 5 different target materials Depending on the power supplies used (RF or DC), both metallic and non-metallic materials can be deposited. Capable of sputtering 5 target materials to produce various compositions via different sputtering times / rates With optional 5 power supplies, 5 target materials can be sputtered at the same time for combinatorial sputtering 16 samples can be deposited in one batch with a mask and a rotating sample holder

|

Input Power | |

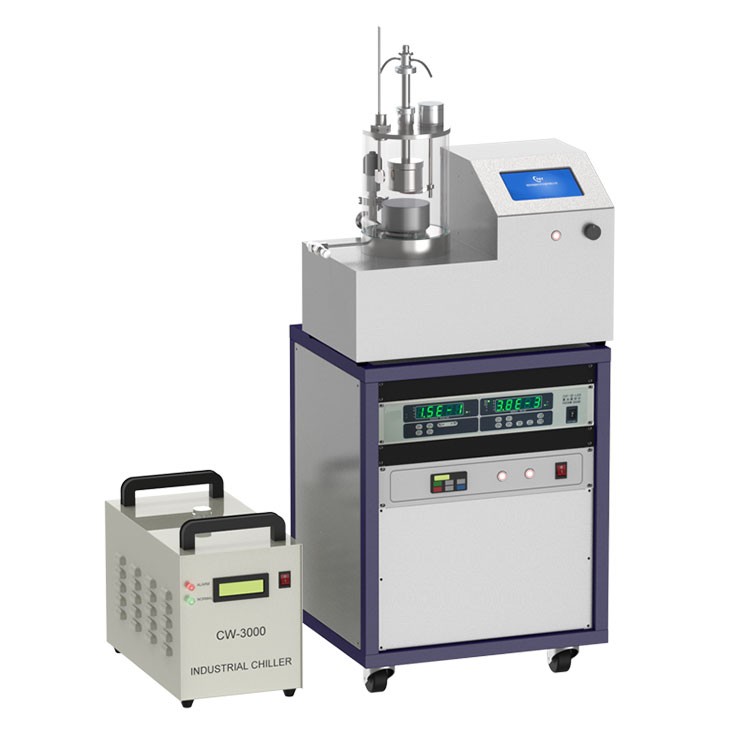

Power Source | One 13.5 MHz,300 W auto-match RF generator is included and connected to the sputtering heads The rotatable switch can activate one sputtering head at a time. Sputtering heads can be switched “in the plasma” without breaking of vacuum during a multilayer process. Multiple RF power supplies are optional, which allows user to sputter multi-target at the same time for combinatorial sputtering Laptop with control software is available at extra cost to control each RF gun's sputtering time and power

|

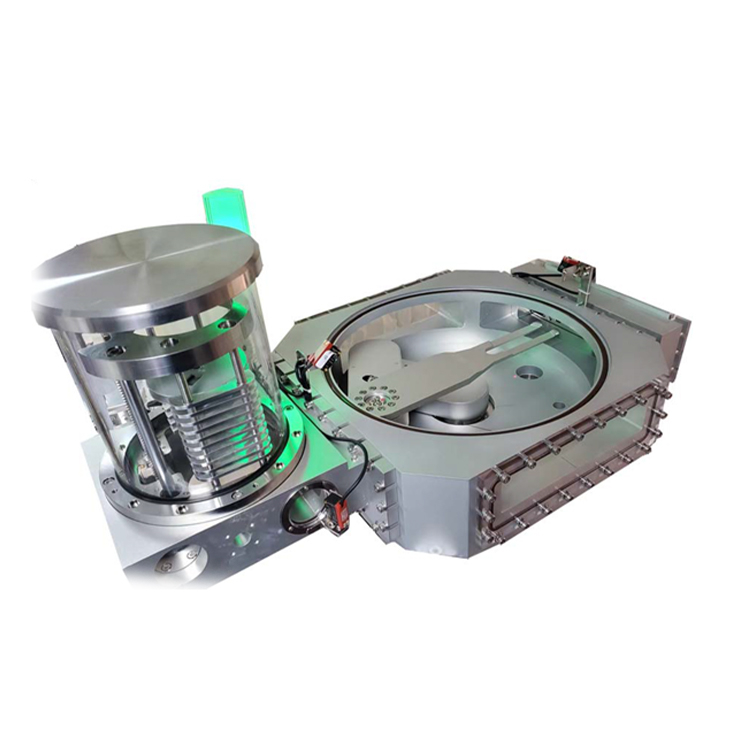

Magnetron Sputtering Head

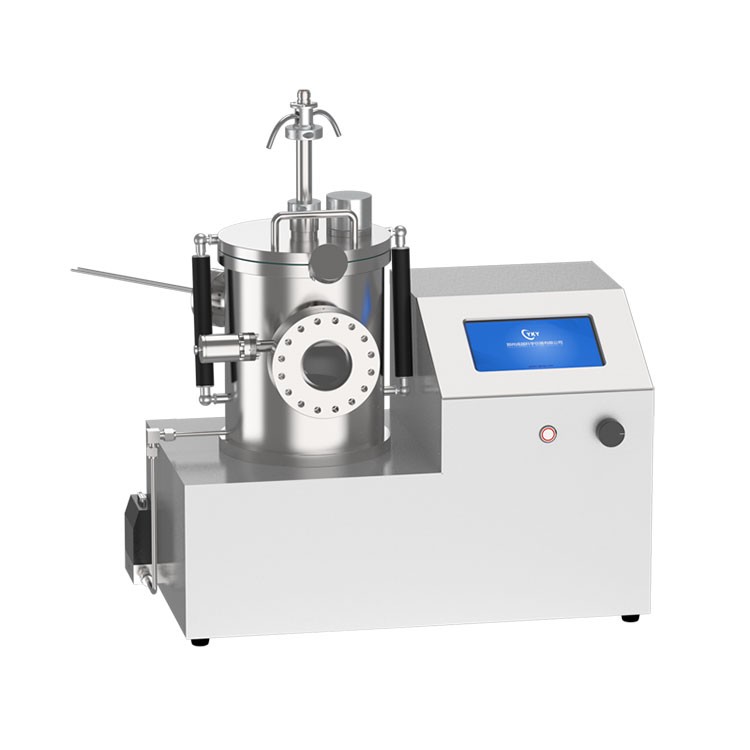

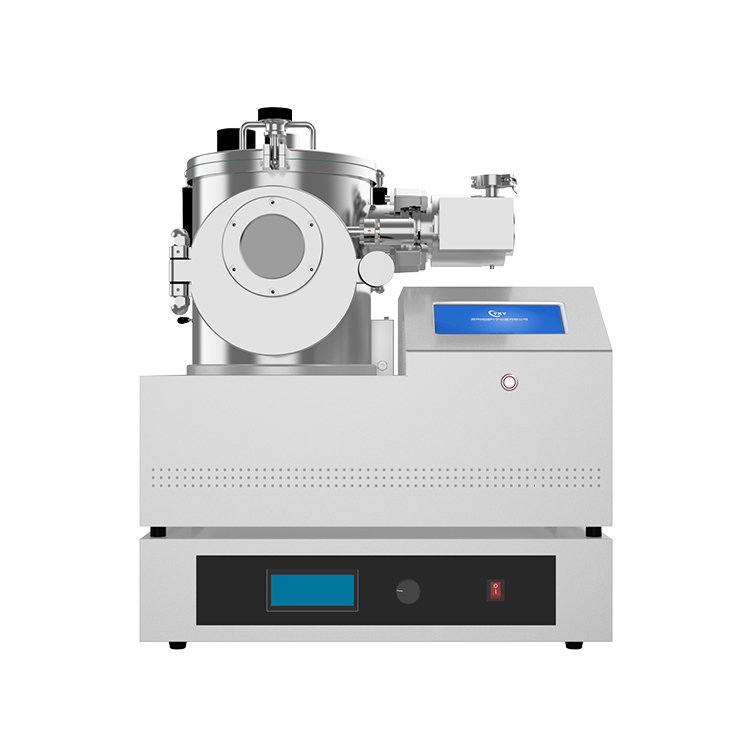

| Five 1" magnetron sputtering heads with water cooling jackets are included and inserted into quartz chamber via quick clamps One manually operated shutter is built on the flange One 10 L/min digitally controlled recirculating water chiller is included for cooling sputtering heads

|

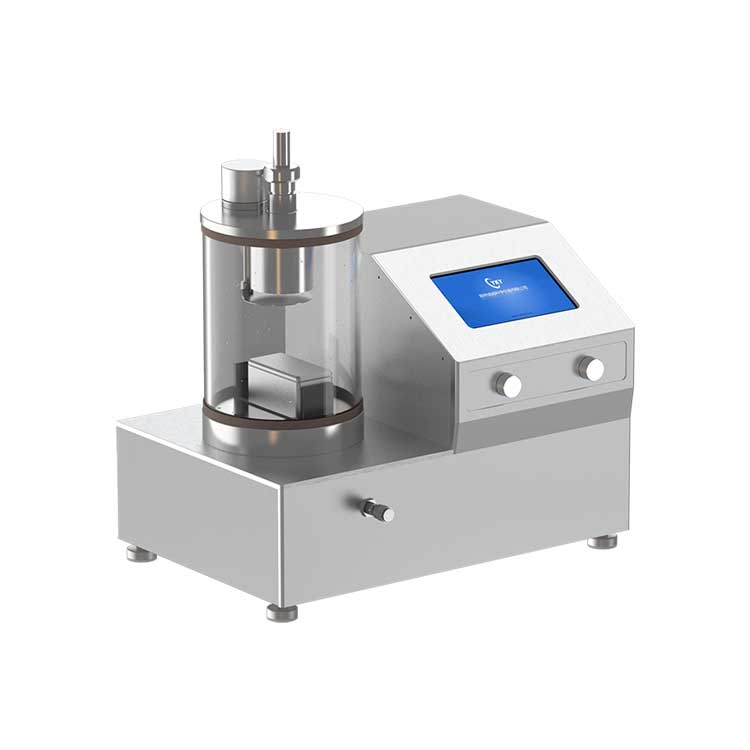

Sputtering Target

| Target size requirement: 1" diameter×1/8" thickness max Sputtering distance range: 50 – 80 mm adjustable Sputtering angle range: 0 – 25° adjustable 1" diameter Cu target and Al2O3 target are included for demo testing

|

Vacuum Chamber | Vacuum chamber is made of 304 stainless steel with reinforcing rib Inside vacuum chamber size: 470 mm L×445 mm D×522 mm H (~105 Liters, 18.5“×17.5"× 20.5") Round 380 mm Dia. hinged type door with 150 mm Dia glass window Temperature range: -15 to 150 °C Vacuum level: 4.0E-5 torr with turbo pump

|

Sample Holder | 150 mm diameter rotatable sample holder for coating 16 sample one one batch with different compositions Sample holder and mask rotation can be controlled manually by a button or automatically by a control software (Optional) The sample holder temperature is adjustable from RT to 600 °C max

|

Vacuum Pump | KF40 vacuum port is built in for connecting to a vacuum pump. A compact turbo pump is included 4.0E-5 Torr with optional turbo pump

|

Net Weight | 60 kg |

Warranty | One years limited warranty with lifetime support |