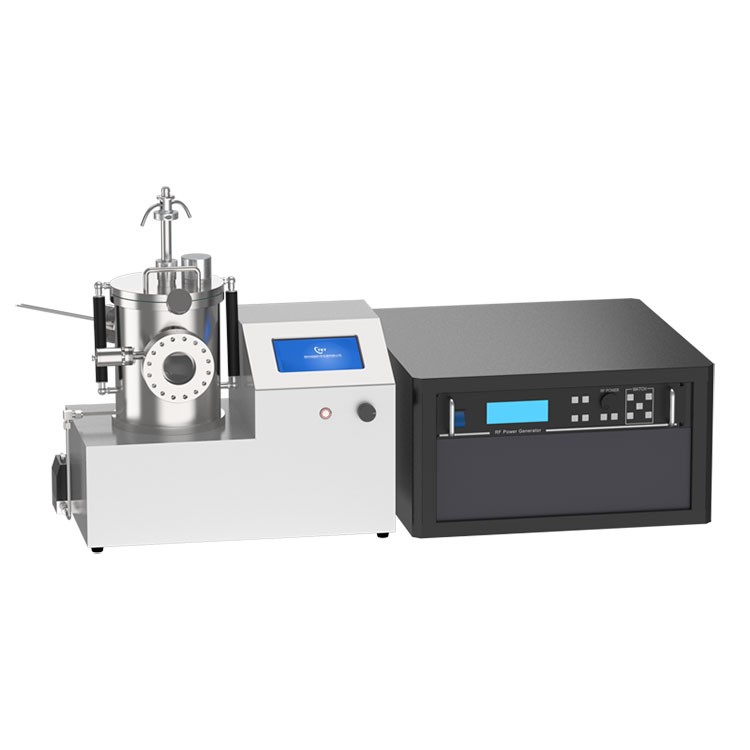

Input & Output Power | Input: 208 - 240VAC, 20 A, 50/60 Hz, single phase Total Power required: 8KW (including pump) other 3 phase voltage is available upon request Output: 5VAC max. and 300A Max.

|

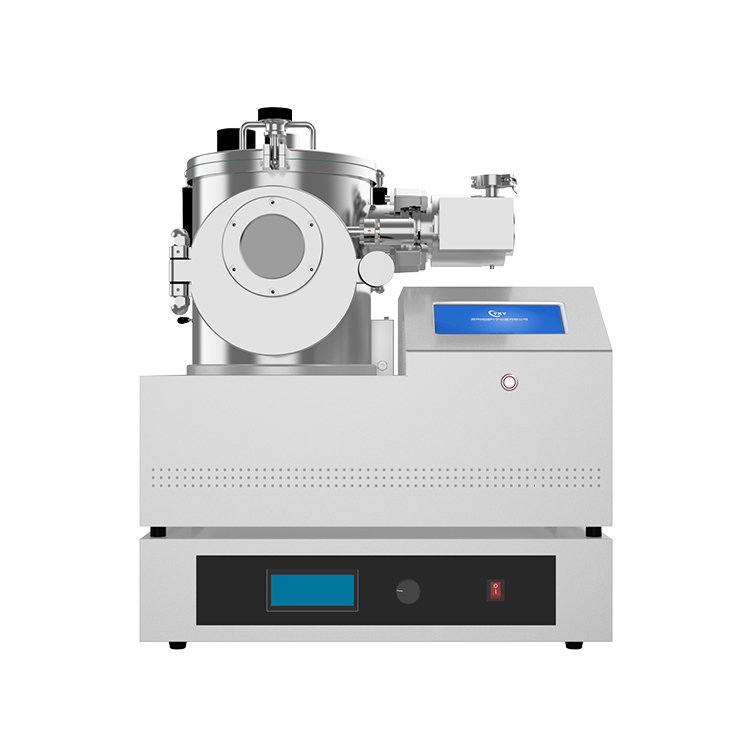

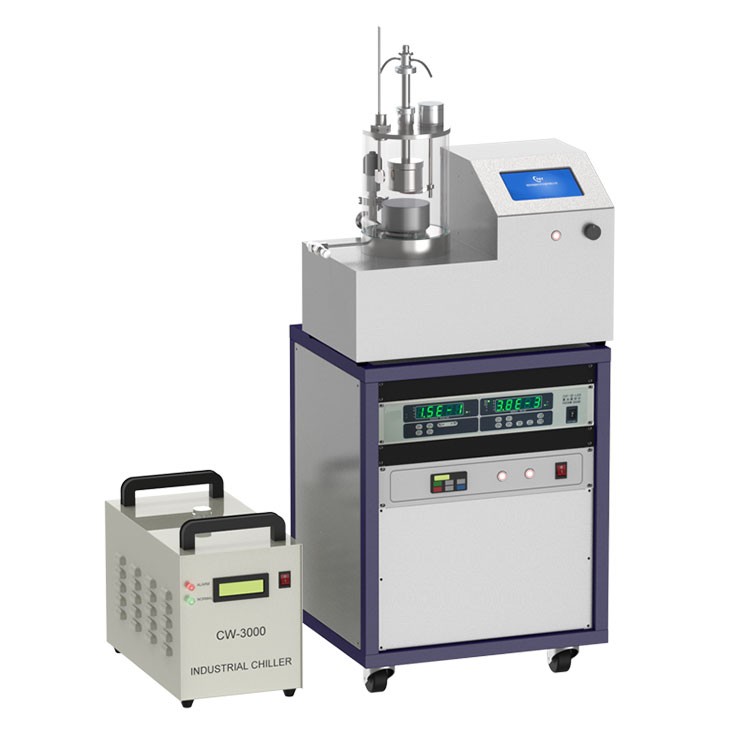

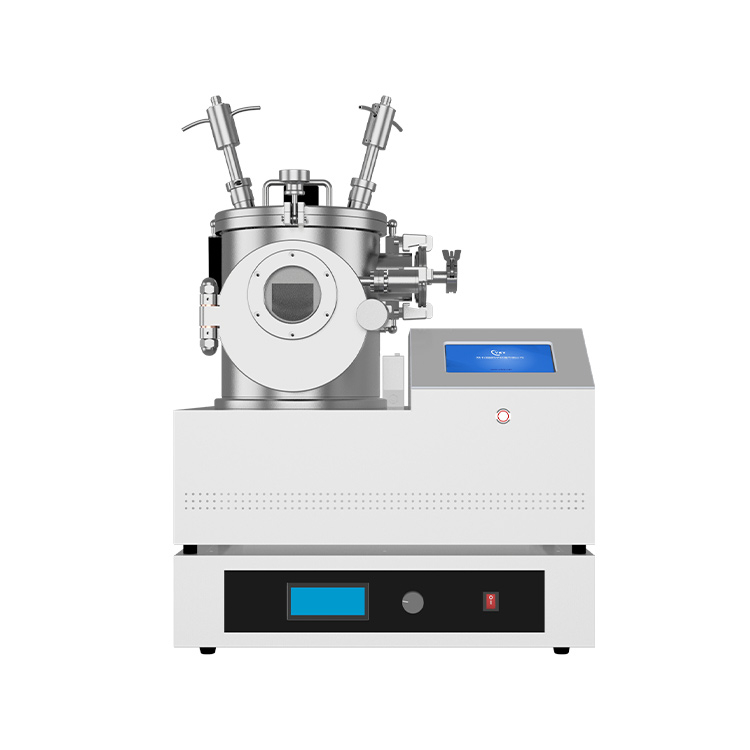

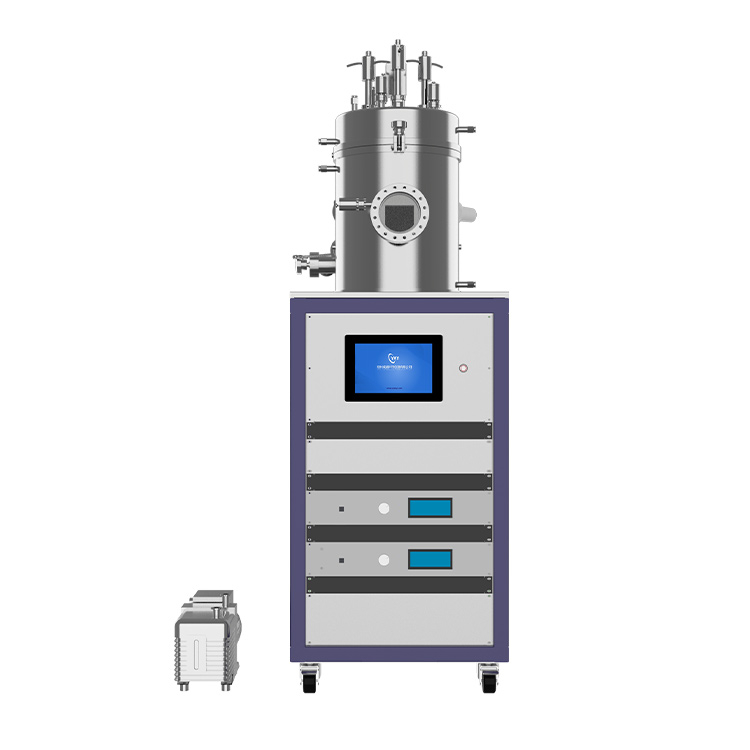

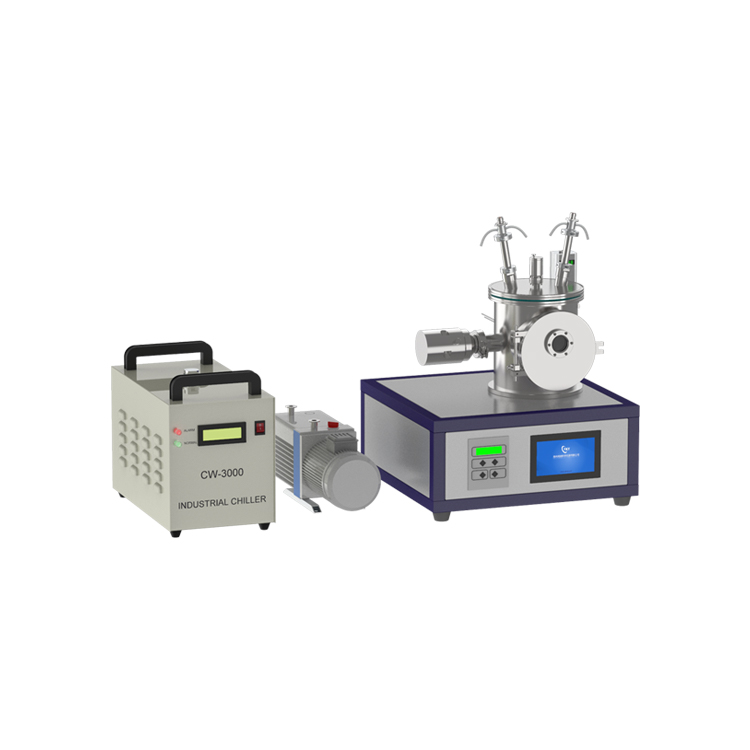

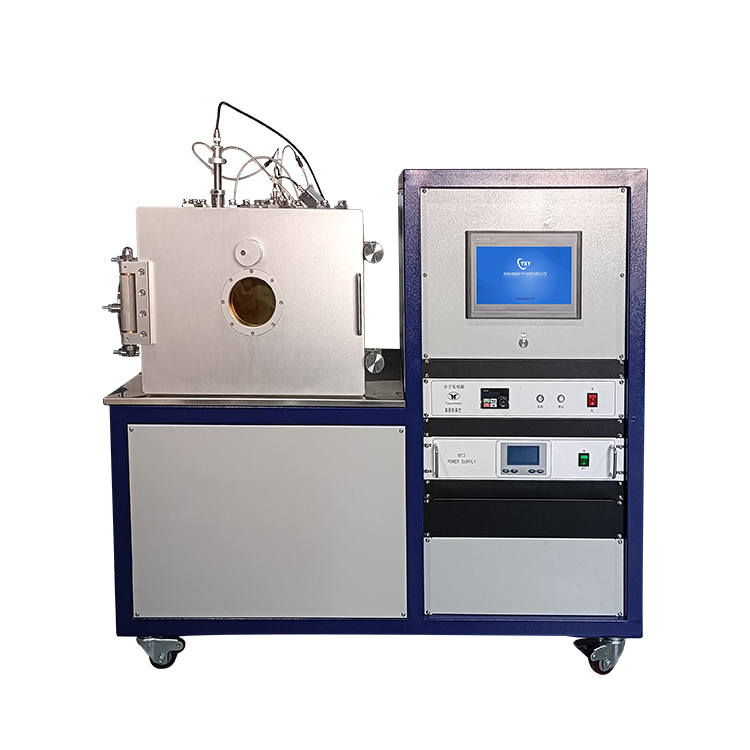

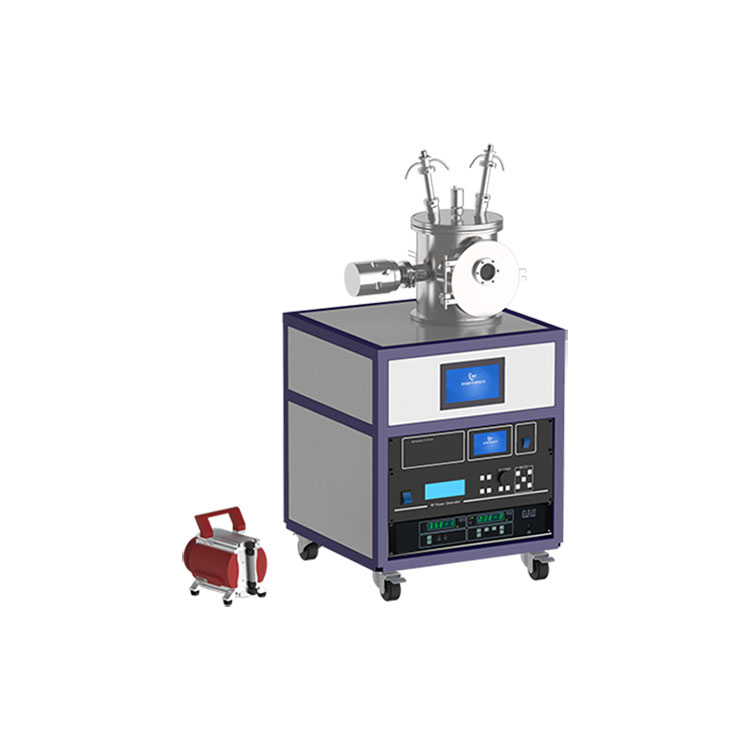

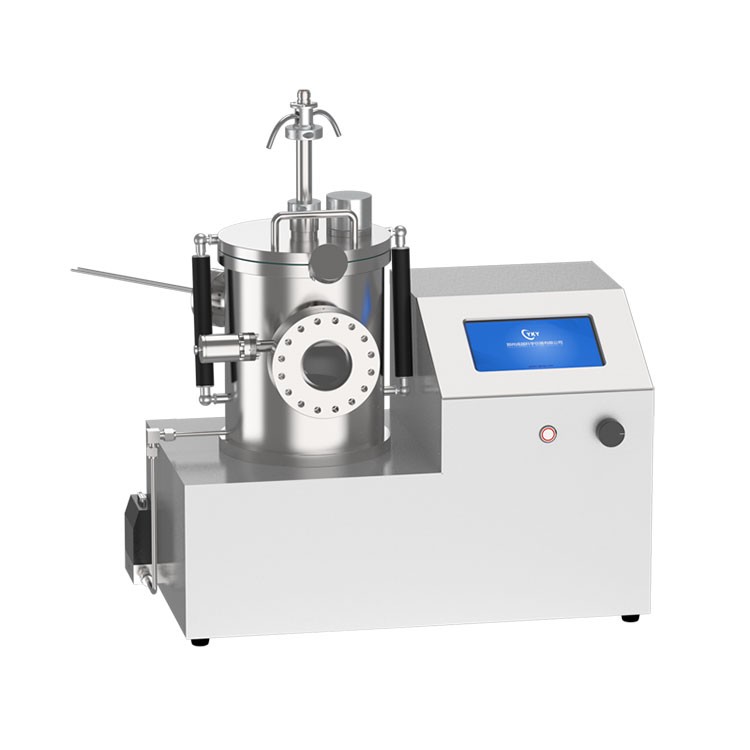

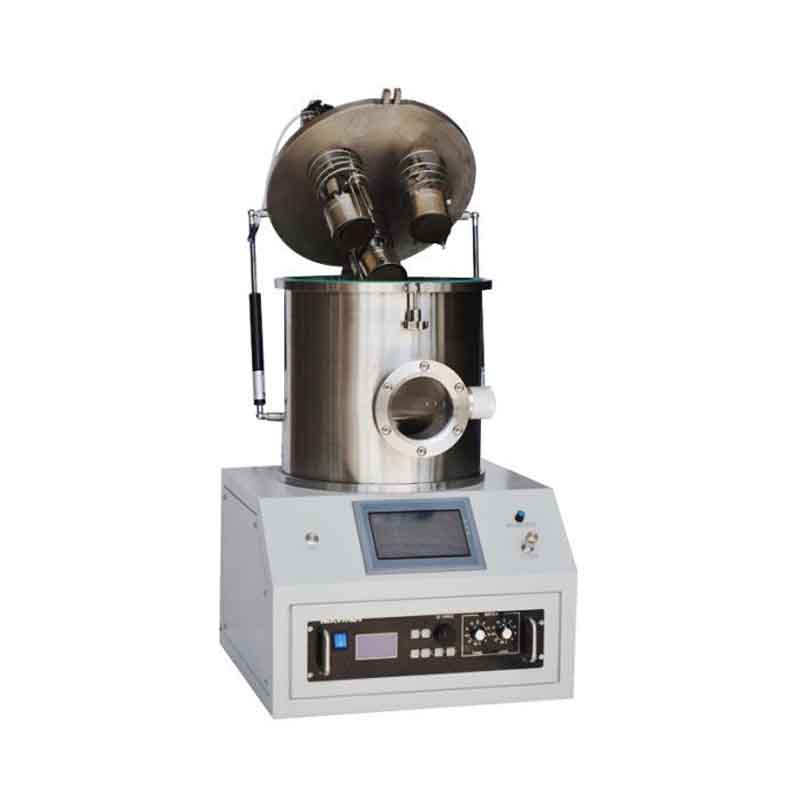

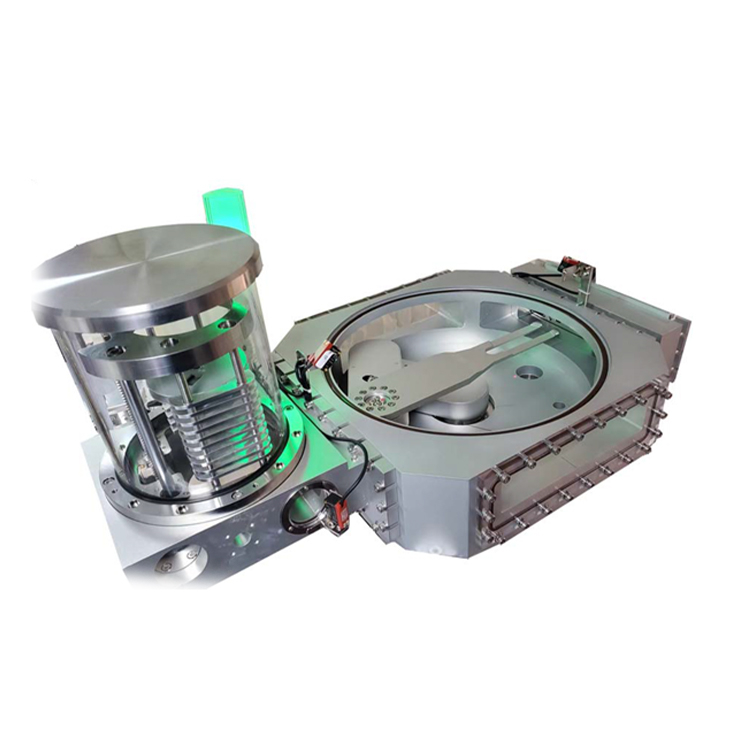

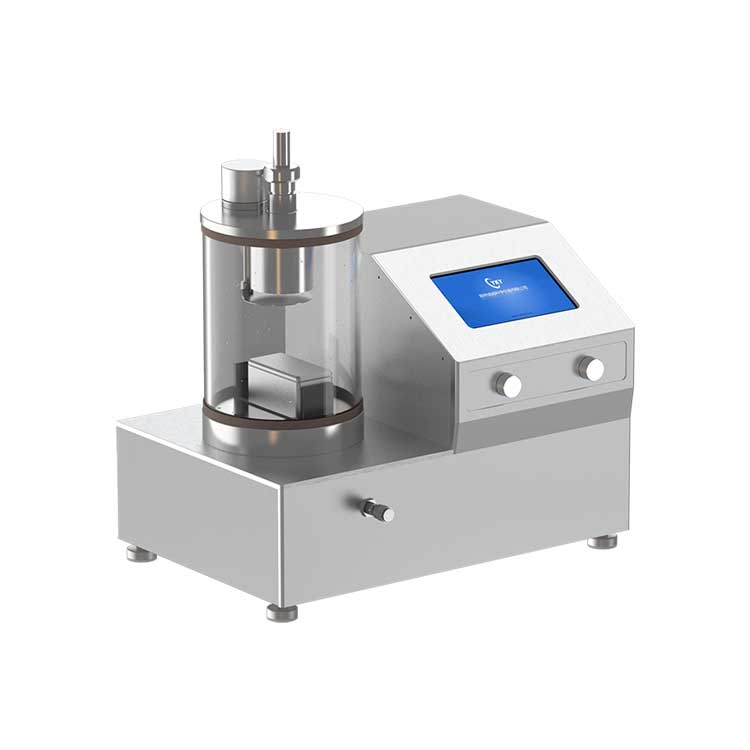

Vacuum Chamber | Stainless steel chamber: 280mm ID.×375 mm Height, (~23Liter) Sand-blasting electrolytic polishing surface 100 mm observation window in front of chamber Hinged type door for easy sample loading Manually operated shutters are on top of each evaporation W boat, which allow evaporating 4 kinds of material one by one 4 KF40 ports built in chamber for connecting to necessary device

|

Vacuum Pump | |

Evaporation Source

&Sample Holder | Four tungsten heating boats are included supported by water cold electrodes Tungsten heating boat has dimension 70mm L x 12 mm W x 3 mm H. Spare W boat is available at extra cost。 Each top of boat has a manual operation shutter Built in manual shutter allows evaporation source can be used without contamination 100 mm diameter rotating sample holder is on top of the chamber with diameter 260mm, which can be heated up to 600°C max. via digital temperature controller with +/1 °C accuracy The distance between evaporation source and sample holder is 150-300 mm adjustable

|

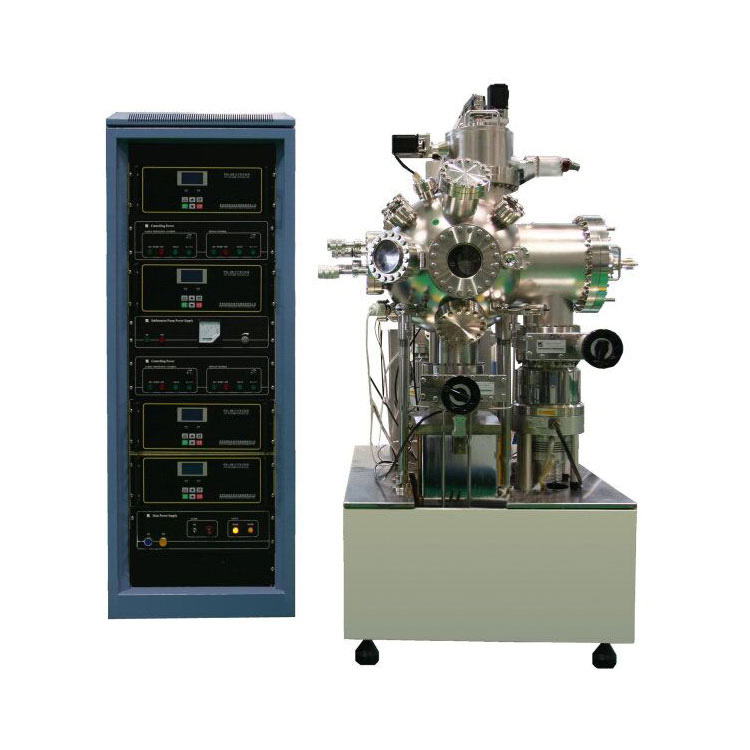

Control Unit | Vacuum, thickness and power control are integrated into one control box Control Unit is separated from vacuum chamber for easy moving You may place the control unit on the top of vacuum station

|

Overall Dimensions | L600mm×W860mm× H1500mm |

Net Weight | 600 kg |

Facility Requirement for Installation | Space: 250 SF with height > 6 feet Power: 208 - 240V AC, single phase with Max 10KW ( 50A breaker) Water: > 15L/minute flowing water required for electrode cooling.

|