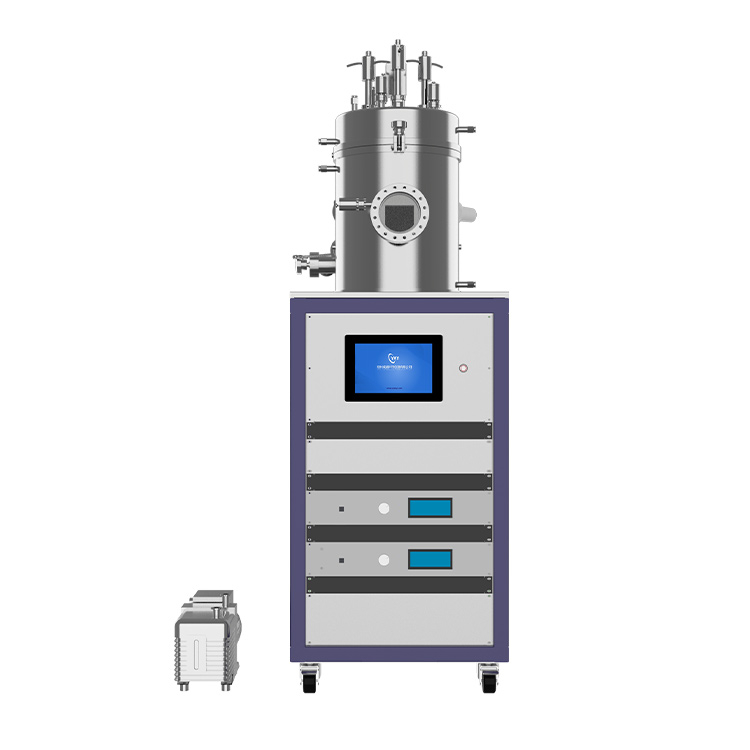

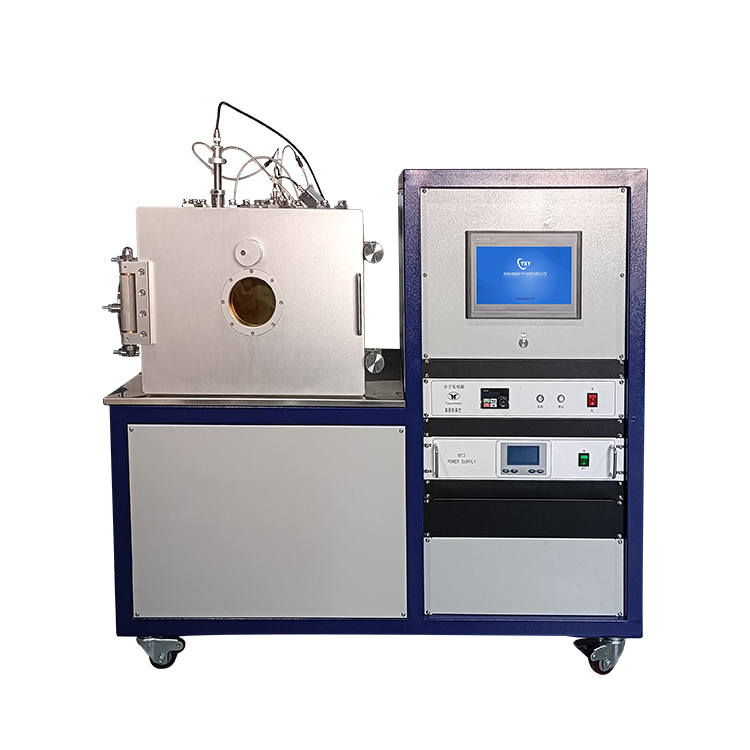

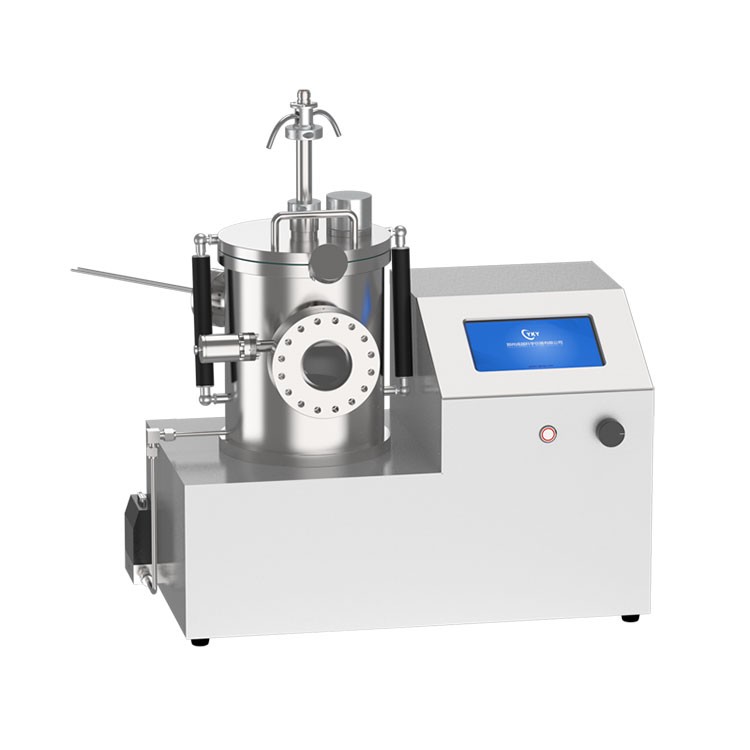

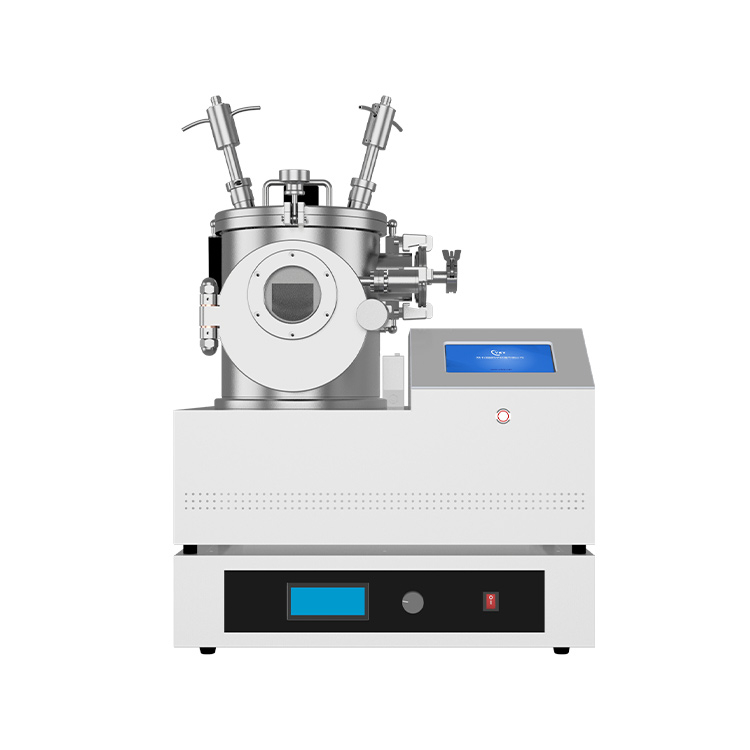

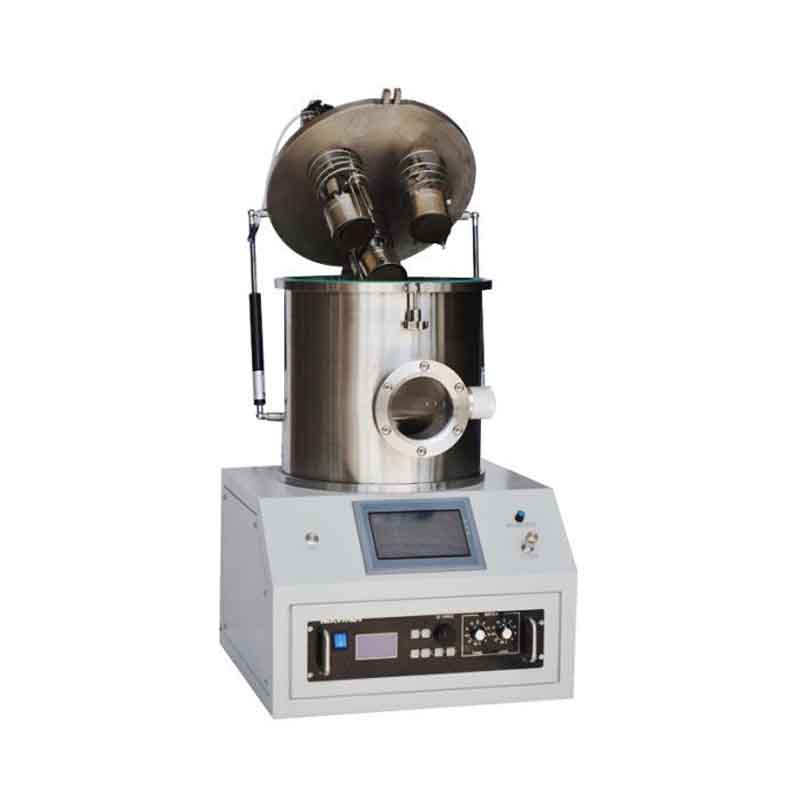

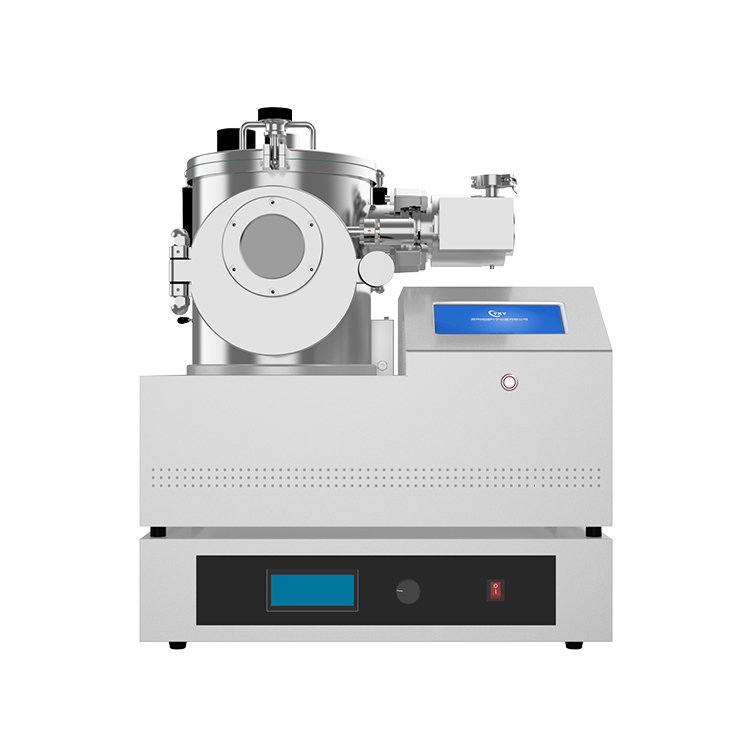

Vacuum chamber | Circular type vacuum chamber,size: dia. 450×350mm |

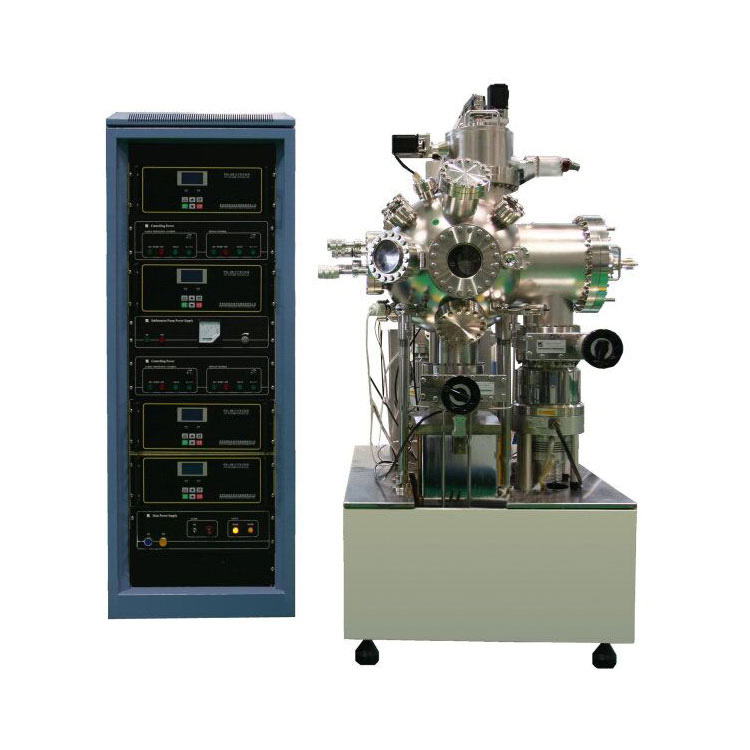

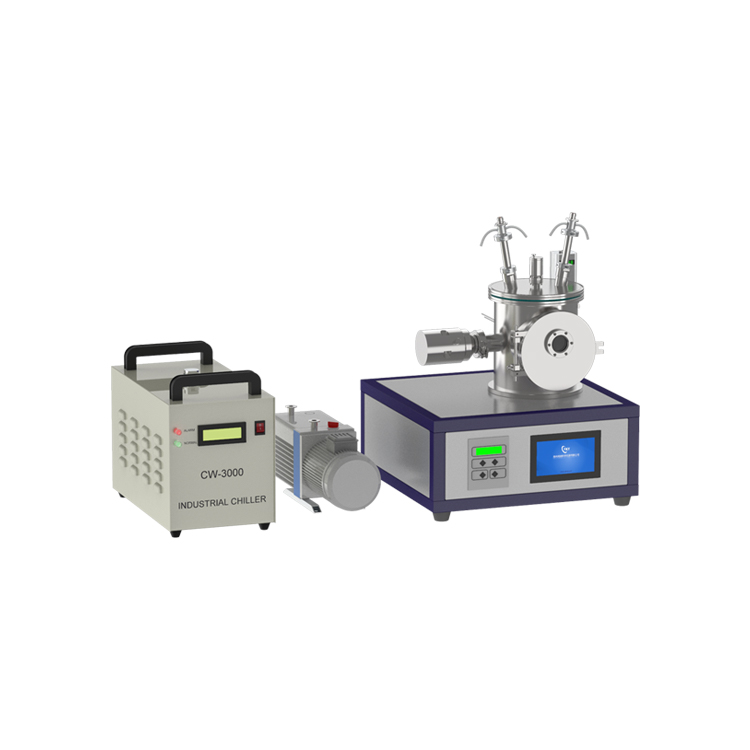

Vacuum system configuration | Compound molecular pump, mechanical pump, gate valve |

ultimate pressure | ≦6.67*10-5Pa(After baking degassing) |

Vacuum recovery time | Up to 6. 6*10-4Pa in 40 minutes. (the system briefly exposes the atmosphere and fills with dry nitrogen to start pumping) |

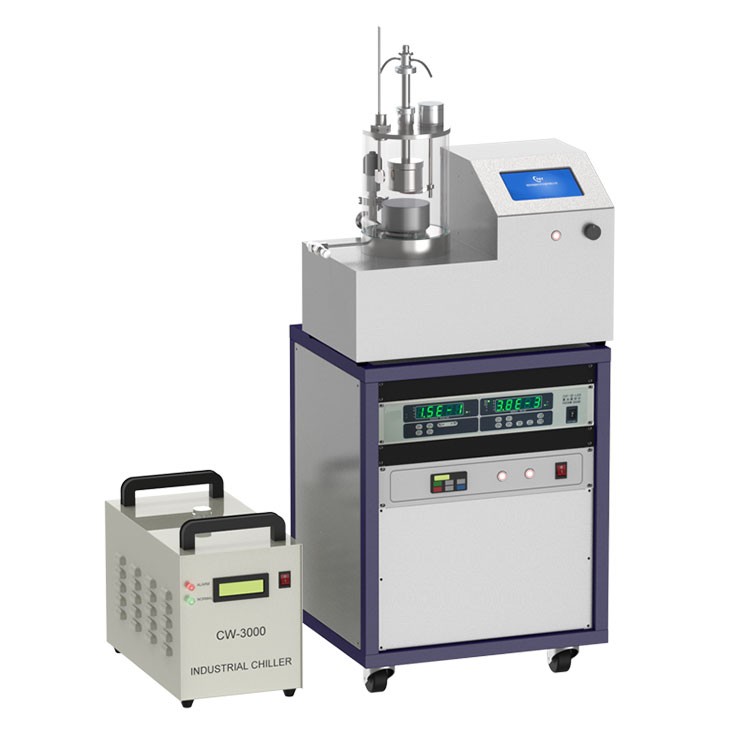

Magnetron target component | 3 sets of permanent magnetic targets; target size dia. 60mm (one of the targets can sputtering ferromagnetic material). The RF beach and DC cutoff of each target are compatible; and the distance between target and sample is adjustable from 90mm to 100mm; when direct upward sputtering, the distance between target and sample is adjustable from 40mm to 80mm. |

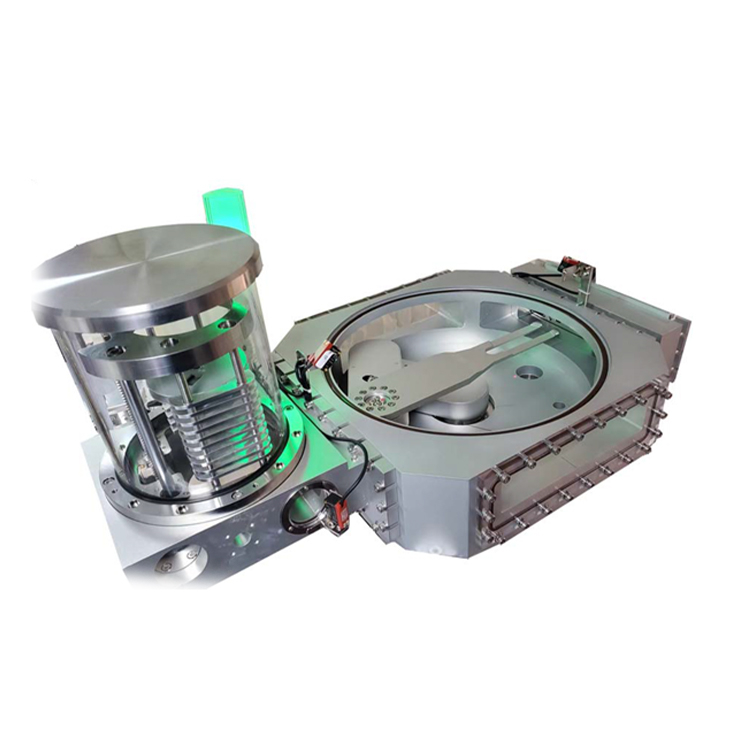

Water-cooling Substrate Heating Revolution Table | Substrate Structure | The substrate heating and water cooling work independently, and the heating furnace can be replaced by water cooling substrates |

Sample size | Dia. 30mm |

Mode of motion | The substrate can rotate continuously, and the rotation speed is 5-10 RPM |

Heating | Max. Temperature 600℃±1℃ |

Substrate Negative Bias | -200V |

Gas channel system | 2-channel Mass Flow Controller (MFC) |

Optional parts 6 station base plate heating revolution table | Removing the single substrate, The water heating platform can be replaced on the rotary table. 6 sheets of 30mm substrates can be placed simultaneously; Among the six stations, one of them is installed with heating furnace, while the rest are natural cooling substrates. Maximum temperature of substrate heating: 600℃±1℃ |

Computer Control System | Control sample rotation, baffle switch, target identification, etc. |

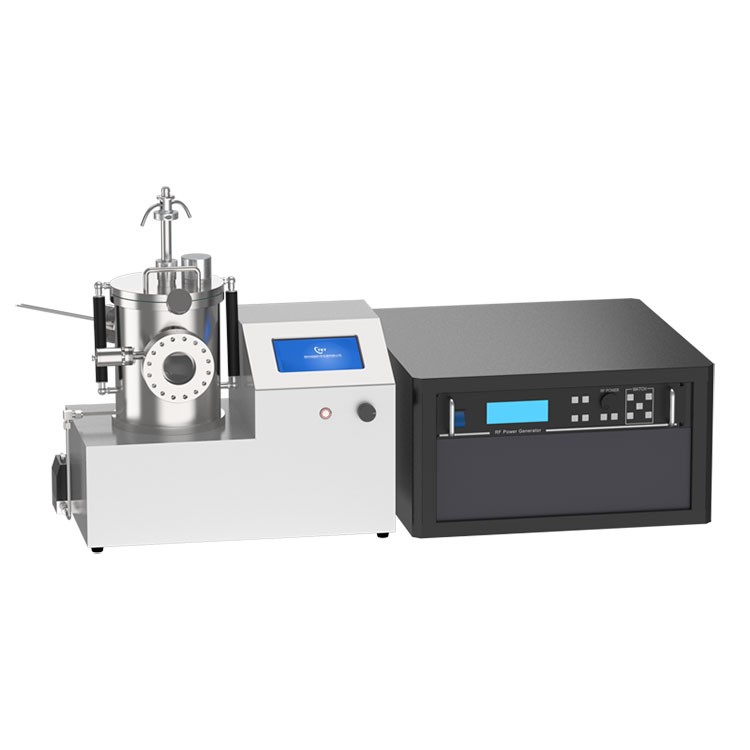

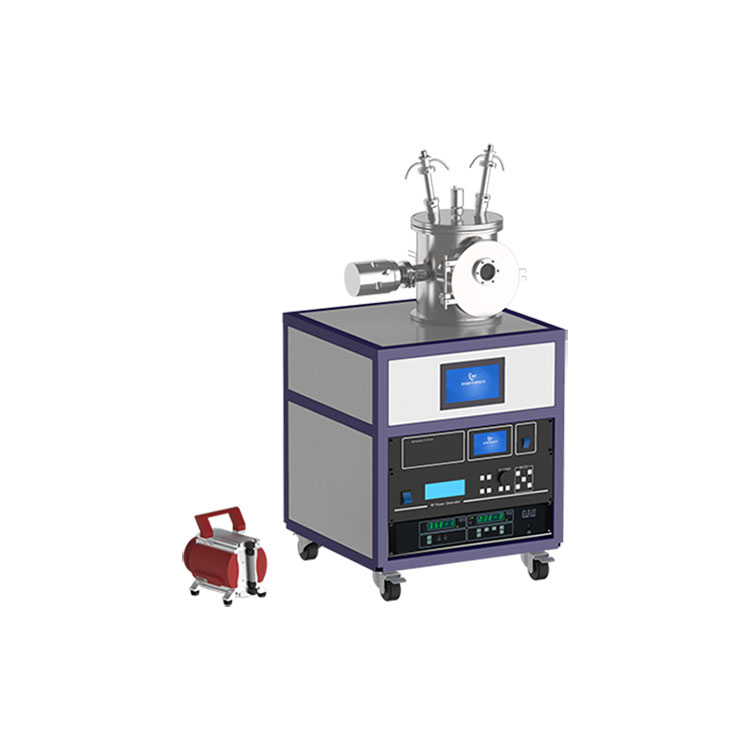

Floor Occupied | Main machine | 1300×800mm2 |

Electrical Cabinet | 700×700mm2 |