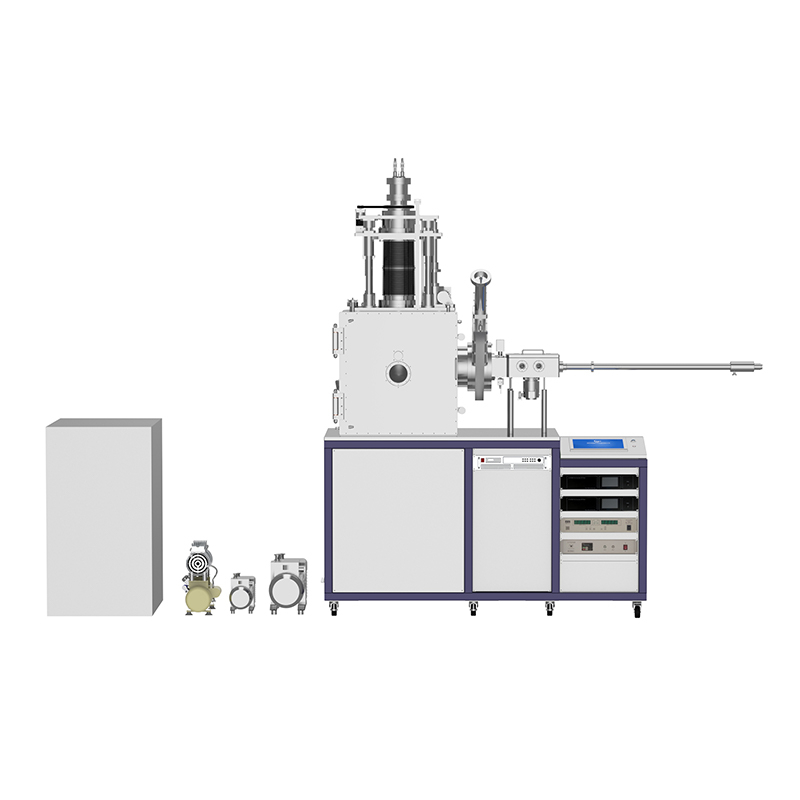

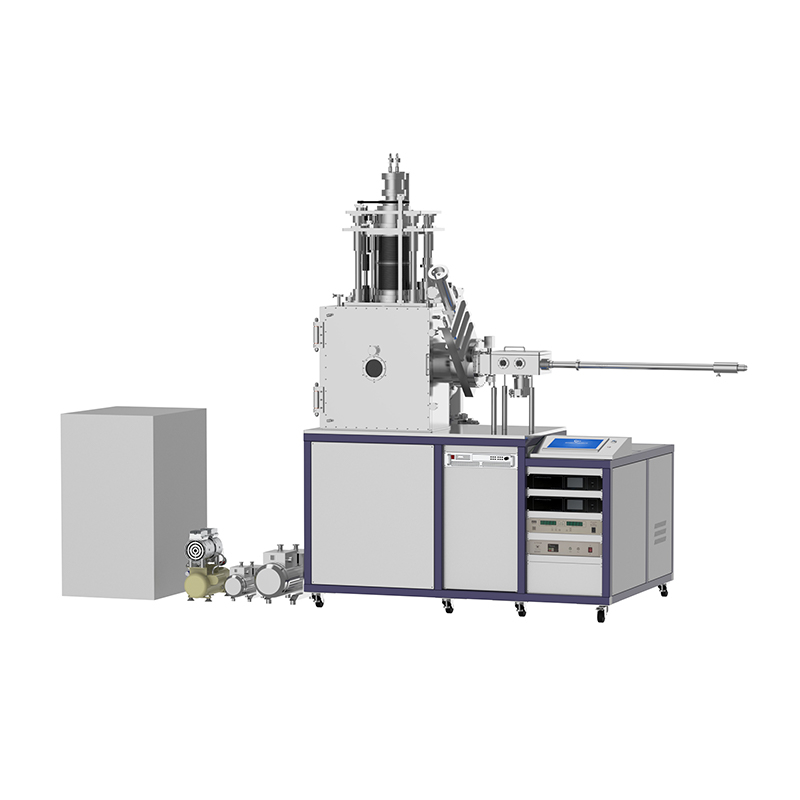

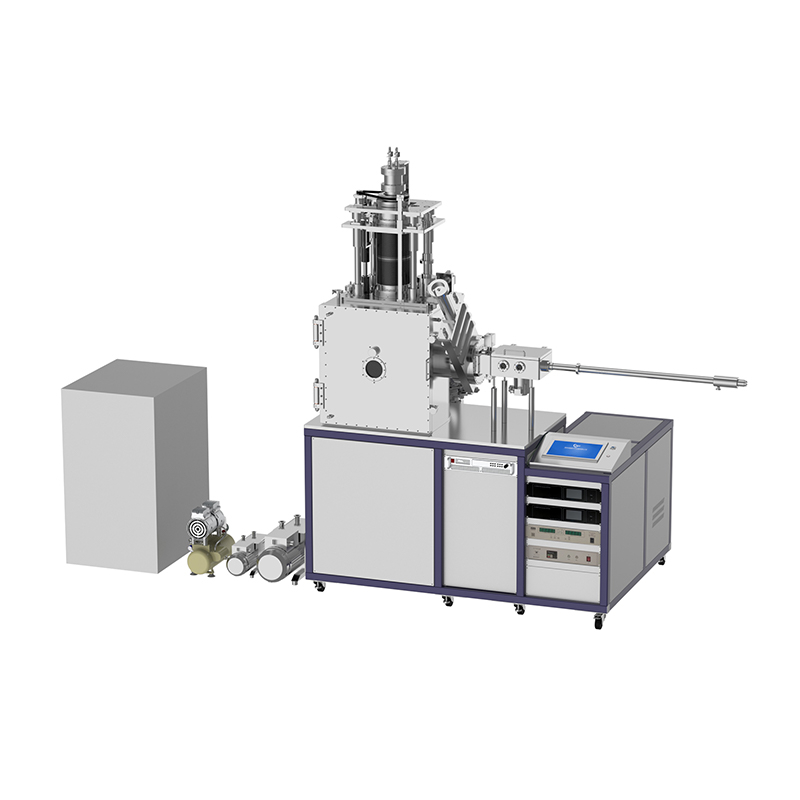

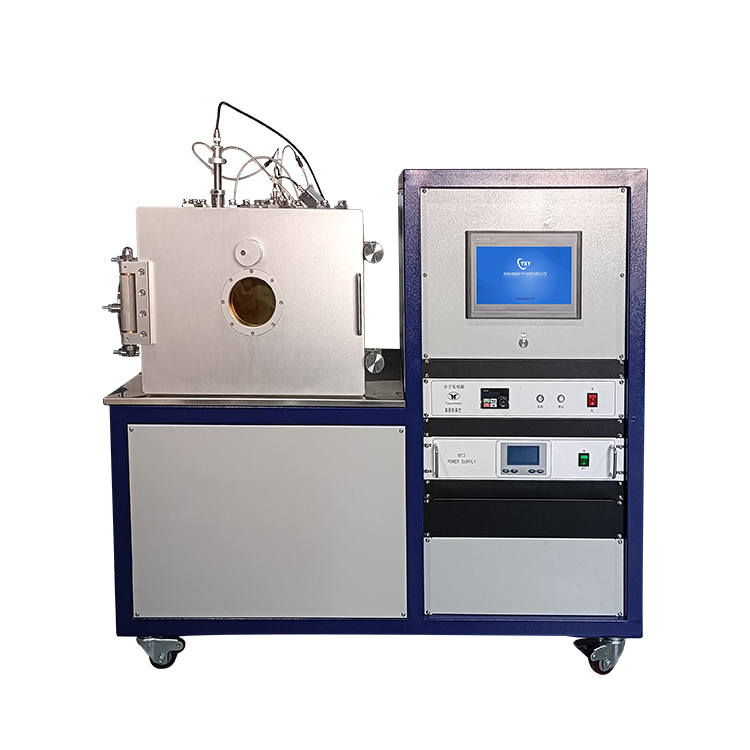

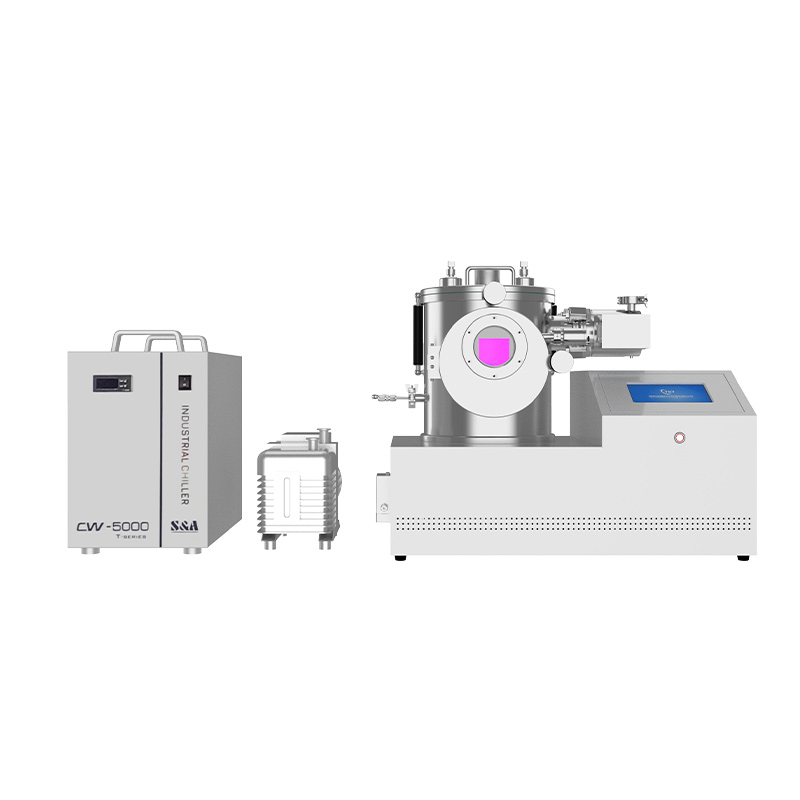

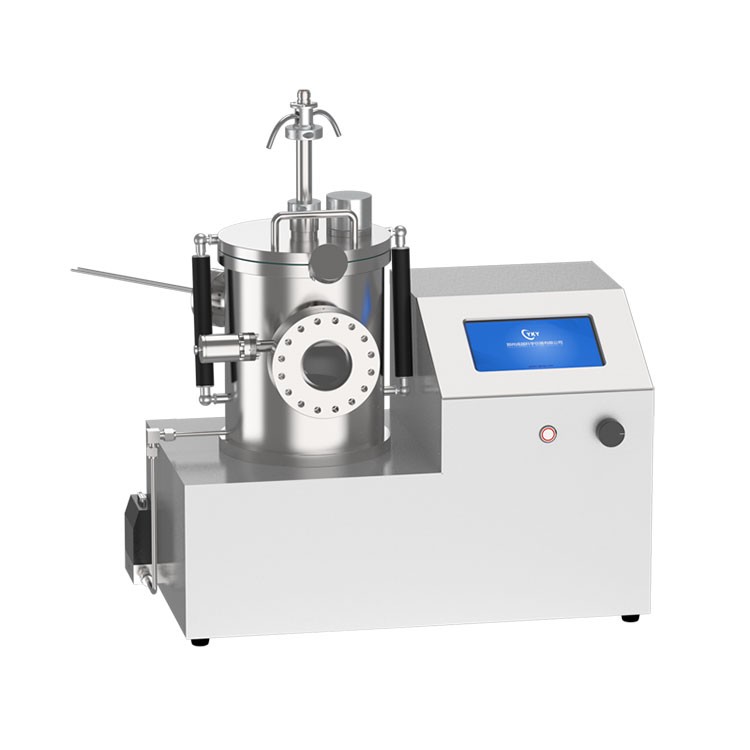

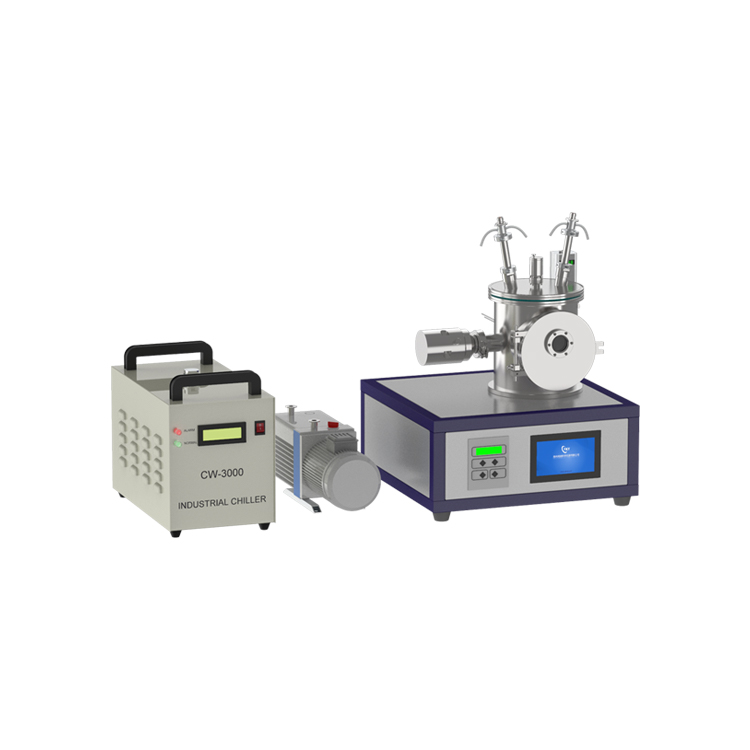

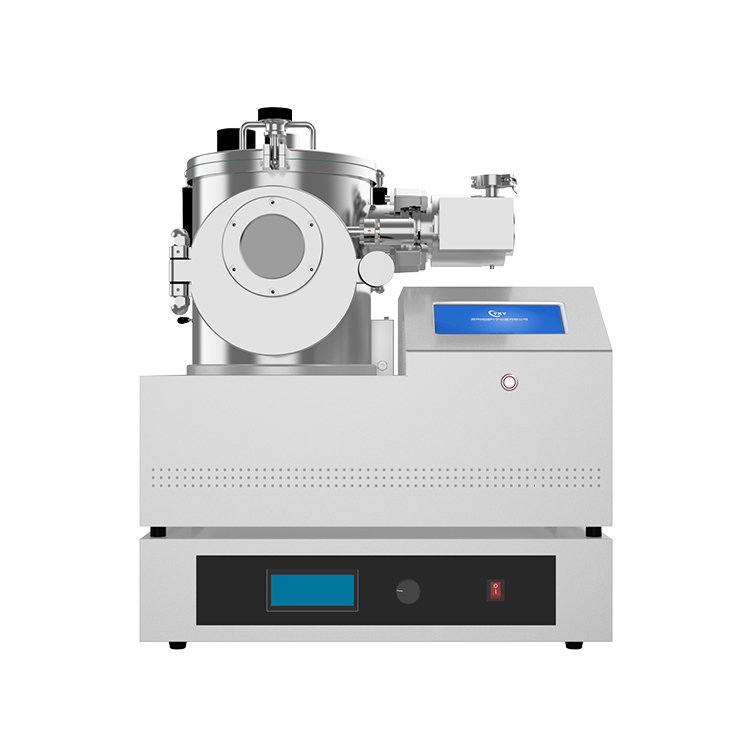

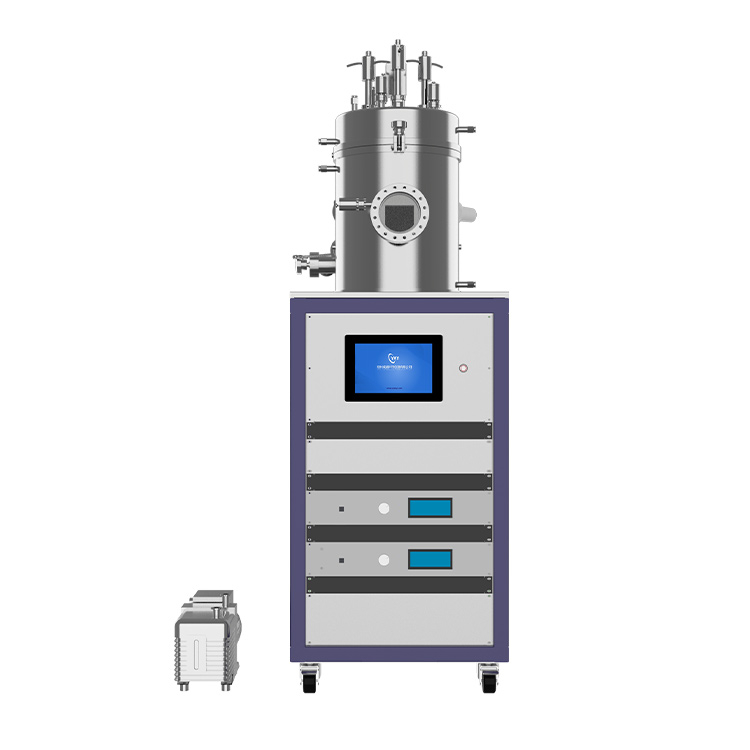

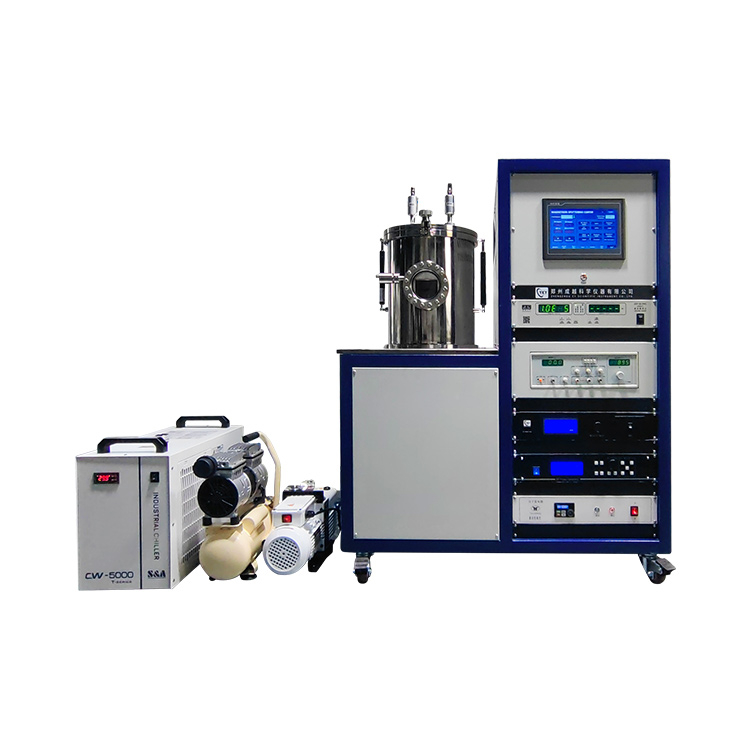

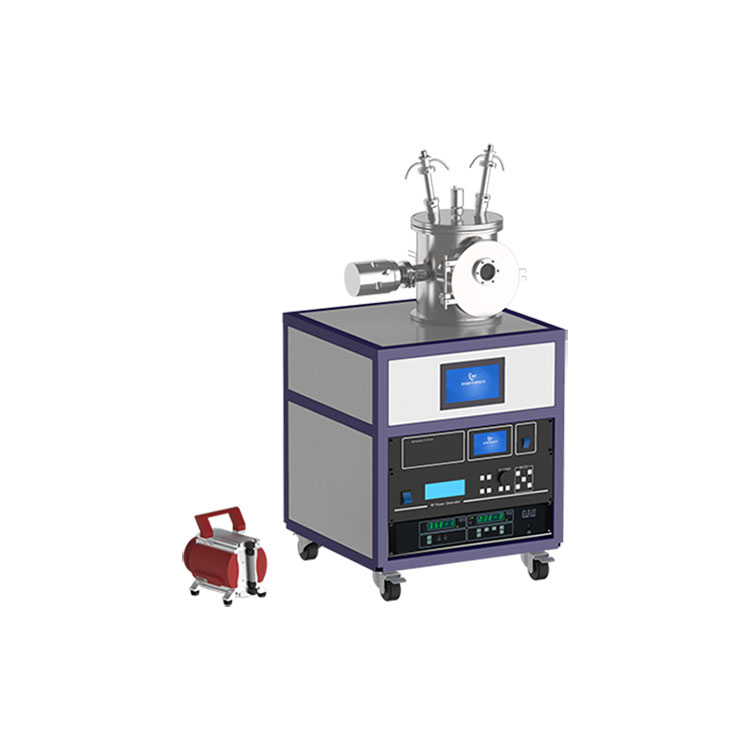

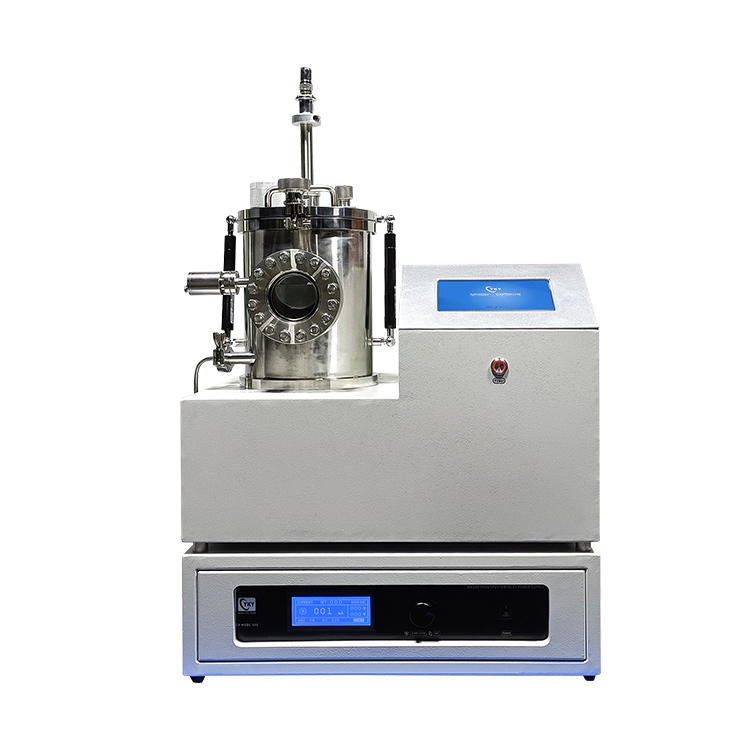

Four-Target Magnetron Sputtering Coater with Load-Lock Chamber

The Four-Target Magnetron Sputtering Coater can be used to prepare single-layer or multi-layer films, including ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, hard coatings, PTFE films, etc

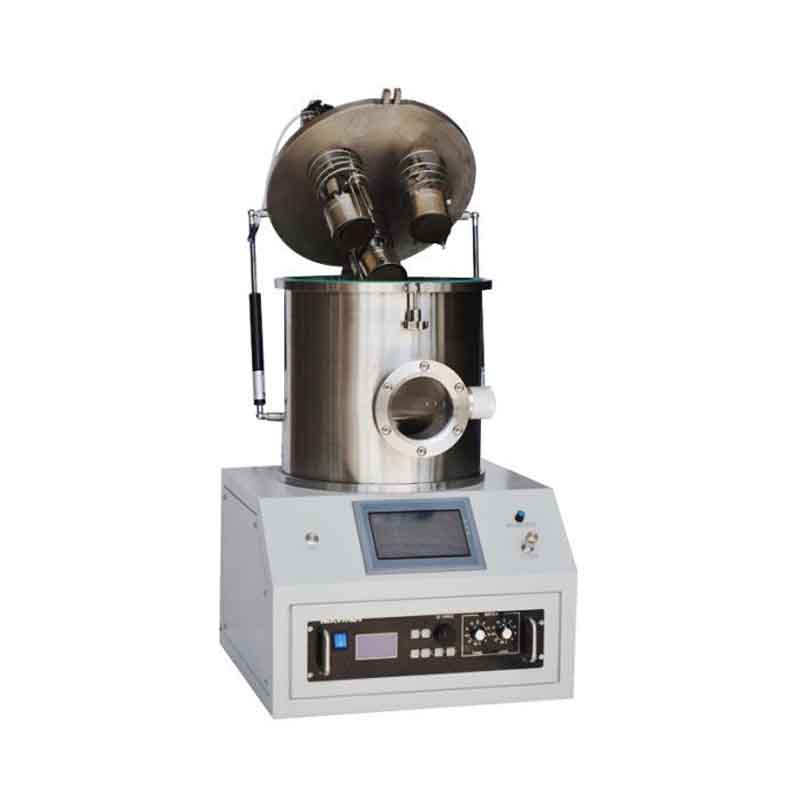

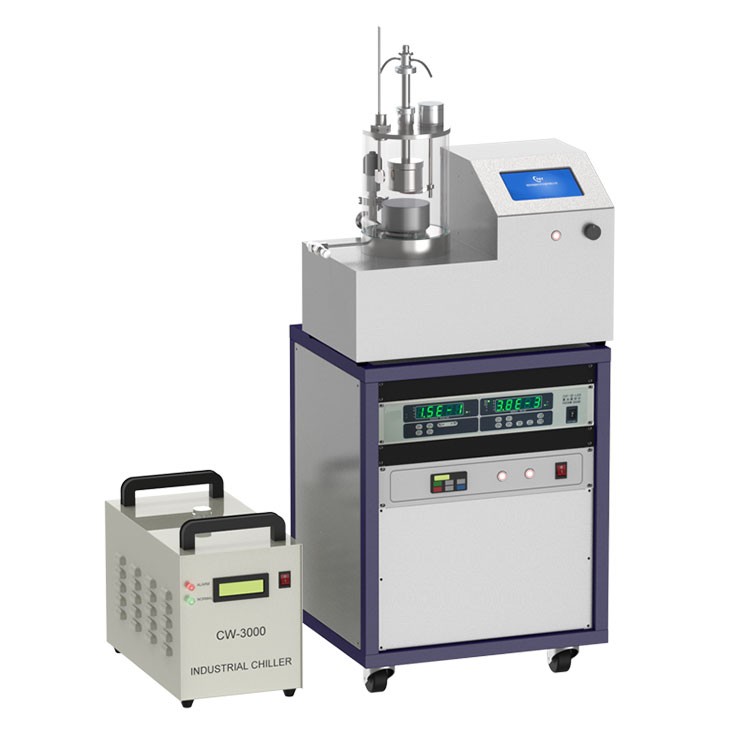

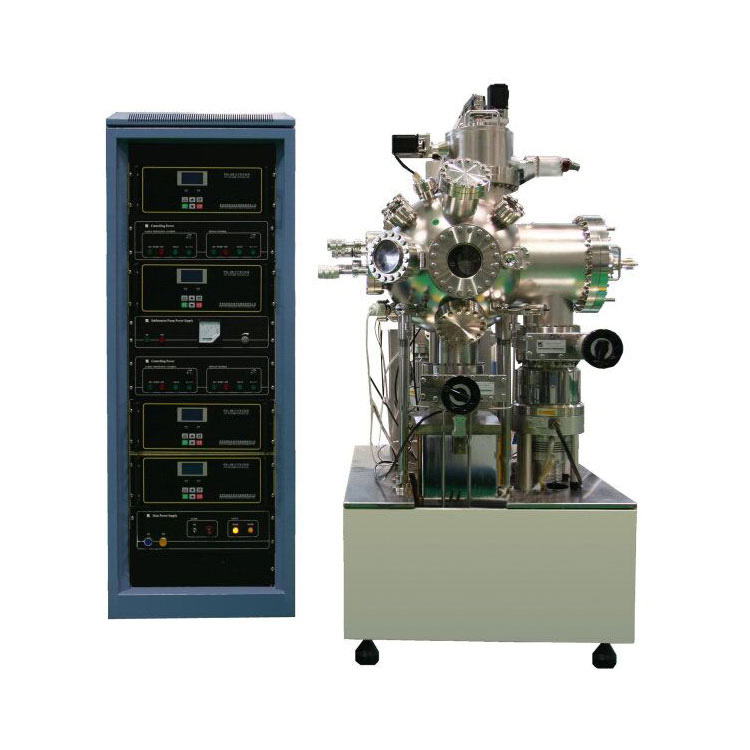

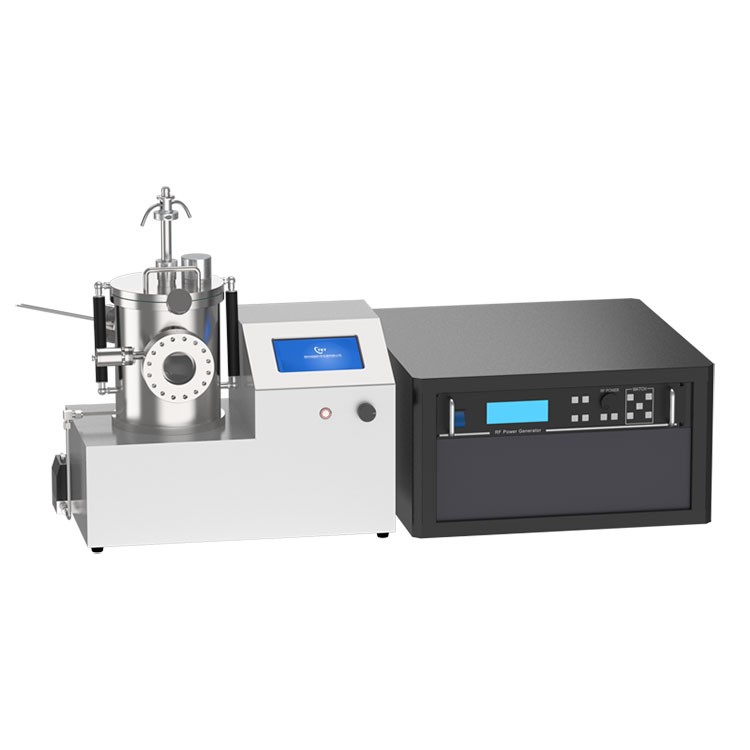

The Four-Target Magnetron Sputtering Coater is a cost-effective magnetron sputtering coating equipment independently developed by our company. It features standardization, modularity, and customizability. Magnetic target sizes of 1 inch, 2 inches, 3 inches, and 4 inches are available for selection, allowing customers to choose based on the size of their substrates. The standard power supply configuration includes a 500W DC power supply and a 500W RF power supply. The DC power supply is suitable for preparing metal films, while the RF power supply is suitable for preparing non-metal films. The four targets can meet the needs for multi-layer or multiple coating cycles. If customers have other coating requirements, other RF power supplies and pulsed power supplies can be customized. Various power supplies are available in power ratings from 300W to 1000W.

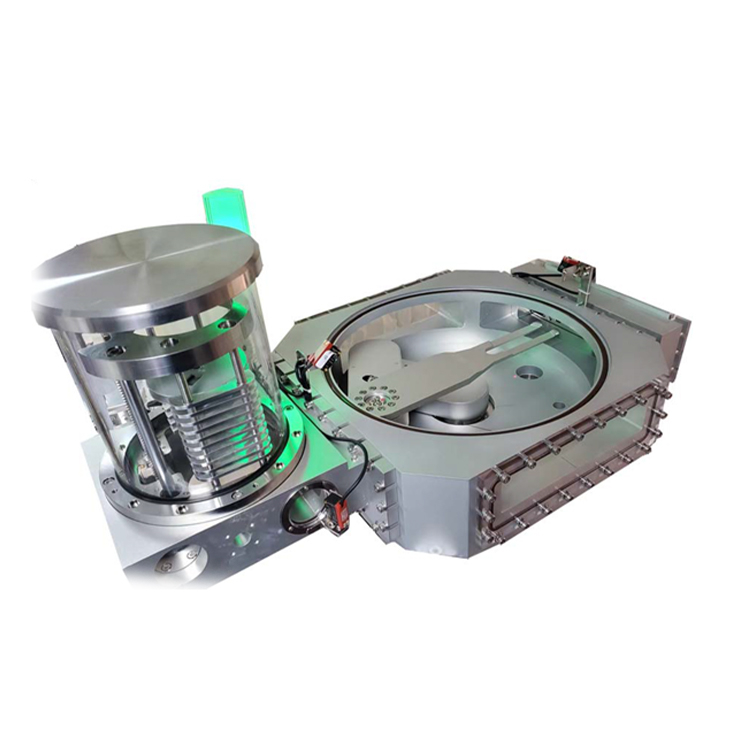

The equipment consists of a main chamber and a load-lock chamber. The load-lock chamber is equipped with a magnetic push rod, and a vacuum gate valve is installed between the two chambers. Users can load samples into the load-lock chamber and perform preliminary vacuum pumping while sputtering work is ongoing in the main chamber. Once sputtering in the main chamber is complete, samples can be transferred into the sample holder of the main chamber via the magnetic push rod. This design reduces the frequency of venting and pumping the main chamber, not only saving significant time but also ensuring better base vacuum, effectively improving coating quality.

The Four-Target Magnetron Sputtering Coater can be used to prepare single-layer or multi-layer films, including ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, hard coatings, PTFE films, etc. Compared to similar equipment, this coater not only has wide applications but also boasts the advantages of compact size and ease of operation, making it an ideal device for preparing material thin films in laboratories. The high vacuum environment ensures that the evaporation process occurs in a high vacuum, guaranteeing that evaporated atoms or molecules reach the substrate directly, avoiding contamination from air impurities and improving film quality. High vacuum conditions also help reduce oxidation of the evaporation material, further enhancing film purity and performance.

Technical Parameters:

Product Name | Four-Target Magnetron Sputtering Coater (DC + RF Power Supplies) |

Model | CY-MSH500X-IIII-DCDCDCRF-SS |

Sample Holder | External Dimensions: φ150mm

Temperature Control Accuracy: ±1℃

Heating Range: Room Temperature ~ 900℃

Adjustable Rotation Speed: 1-20 rpm |

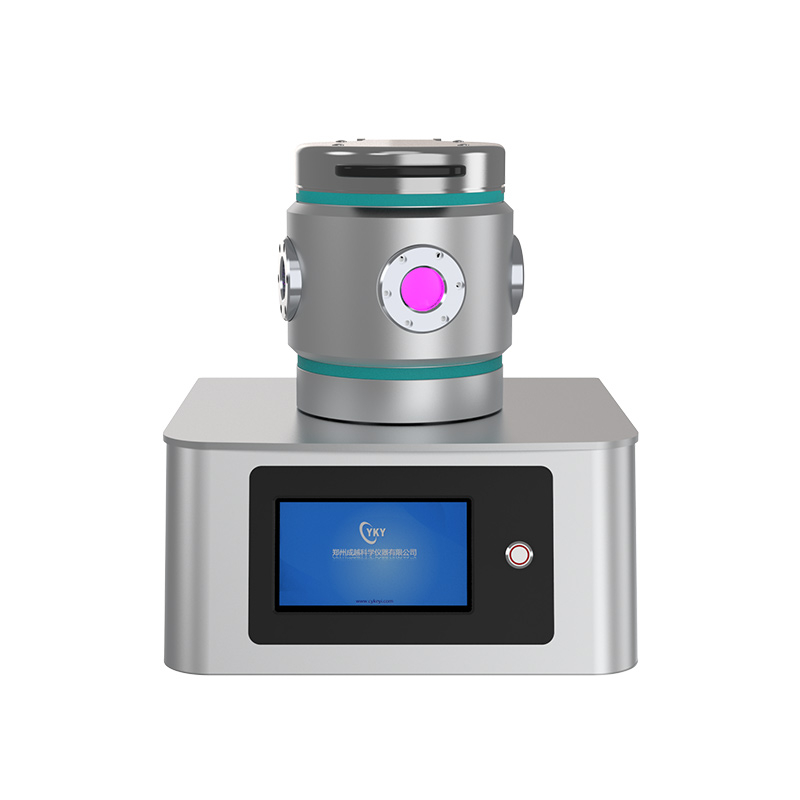

Magnetron Target Guns | Sputtering Direction: Downward Sputtering

Adjustable Angle for Swivel Targets: -45° to 45°, equipped with pneumatic shutter

Target Dimensions: Diameter 4 inches, Thickness ≤3mm

Insulation Voltage: >2000V

Quantity: Three 4-inch swivel targets; One 4-inch fixed target

Cooling Method: Water-cooled |

Vacuum Chamber | Chamber Type: D-shaped Chamber

Chamber Dimensions: Φ500mm × 500mm

Chamber Material: 304 Stainless Steel

Viewport: Quartz window, Diameter φ100mm

Opening Method: Front door opening |

Gas Control | Flow Control: 3 Mass Flow Controllers:

Range: 0~500 SCCM

Range: 0~100 SCCM

Range: 0~20 SCCM |

Bipolar Pulse Magnetron Sputtering Power Supply | Input Voltage: 380VAC ±10%, Three-phase four-wire system, 50-60Hz

Output Power: 0-5KW

Output Voltage: 0-1000V

Output Current: Max. 9A (at constant power)

Output Frequency: 1KHz -150KHz

Output Characteristics: Constant Current / Constant Power / Constant Voltage

Cooling Method: Air-cooled

Communication Interface: 0-5V or 0-10V analog, RS-485

Duty Cycle: 100%

Quantity: 1 unit |

RF Power Supply | Power Rating: 1000W

Power Output Range: 0W-1000W

Maximum Output Power: 1000W

Maximum Reflected Power: 130W

RF Frequency: 13.56MHz +/-0.005% stability

Quantity: 1 unit |

DC Power Supply | Power Rating: 1000W

Quantity: 2 units |

Molecular Pump | Pump Speed: 1200 L/s

Cooling Method: Water-cooled

Achievable Vacuum: 9.0×10⁻⁴ Pa

Backing Pump Speed: 4 L/s

Combination Vacuum Gauge: Range 10⁻⁵ Pa ~ 10⁵ Pa

Quantity: 1 set

Vacuum Valve: Electrically Controlled Pneumatic Valve |

Load-Lock Chamber | Chamber Dimensions: Compatible with wafers up to 6 inches

Equipped Molecular Pump Set:

Backing Pump: VRD-4, Pump Speed 1.1 L/s

Molecular Pump: Japanese TG60F, Pump Speed 60 L/s |

Film Thickness Monitor | Quantity: 1 set

Number of Channels: Single-channel

Measurement Accuracy: 1 Å

Standard Sensor Quartz Crystal: 6MHz

Compatible Quartz Crystal Size: φ14mm |

Water Chiller | Temperature Control Range: 10~25℃

Rated Cooling Capacity: 0.75kW

Flow Rate: 10 L/min

Coolant: Purified Water |

Air Compressor | Speed: 1380 RPM

Flow Rate: 40 L/min

Rated Exhaust Pressure: 0.7 MPa |

Control System | PLC + 14.3 inch Touch Screen |